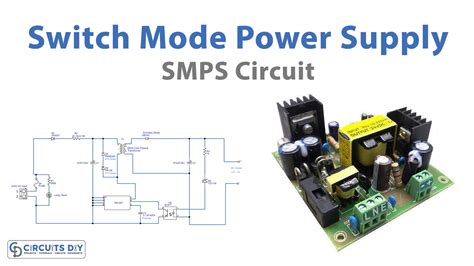

What is an SMPS Circuit?

An SMPS (Switched-Mode Power Supply) circuit is a power supply that uses a switching regulator to efficiently convert electrical power from one form to another. Unlike linear power supplies, which use a transformer and linear regulators to step down voltage and control output, SMPS circuits employ high-frequency switching and pulse-width modulation (PWM) to regulate the output voltage or current.

SMPS circuits are widely used in various electronic devices, such as computers, smartphones, televisions, and industrial equipment, due to their high efficiency, compact size, and ability to handle a wide range of input voltages.

How Does an SMPS Circuit Work?

The basic working principle of an SMPS circuit involves the following stages:

-

Rectification: The input AC voltage is converted to DC voltage using a bridge rectifier and a filter capacitor.

-

High-frequency switching: The DC voltage is then fed to a high-frequency switching element, typically a MOSFET or IGBT, which rapidly turns on and off to create a pulsed waveform.

-

Transformer: The pulsed waveform is applied to the primary winding of a high-frequency transformer, which steps up or down the voltage depending on the turns ratio.

-

Rectification and filtering: The secondary winding of the transformer outputs a pulsed waveform, which is then rectified and filtered to produce a smooth DC output voltage.

-

Feedback and control: A feedback circuit continuously monitors the output voltage or current and adjusts the switching duty cycle to maintain the desired output level. This is typically achieved using pulse-width modulation (PWM) or pulse-frequency modulation (PFM) techniques.

Types of SMPS Circuits

There are several types of SMPS circuits, each with its own advantages and applications:

1. Buck Converter (Step-Down Converter)

A buck converter steps down the input voltage to a lower output voltage. It is commonly used in applications where a lower voltage is required, such as in battery-powered devices or for powering low-voltage digital circuits.

2. Boost Converter (Step-Up Converter)

A boost converter steps up the input voltage to a higher output voltage. It is used in applications where a higher voltage is needed, such as in LED drivers or for powering high-voltage loads.

3. Buck-Boost Converter

A buck-boost converter can both step up and step down the input voltage, depending on the duty cycle of the switching element. This versatility makes it useful in applications where the input voltage may vary above and below the desired output voltage.

4. Flyback Converter

A flyback converter is an isolated SMPS topology that uses a single switching element and a transformer to provide voltage conversion and galvanic isolation. It is commonly used in low-power applications, such as in phone chargers or small power adapters.

5. Forward Converter

A forward converter is another isolated SMPS topology that uses multiple switching elements and a transformer to provide voltage conversion and galvanic isolation. It is typically used in medium-power applications, such as in computer power supplies or industrial equipment.

Advantages of SMPS Circuits

SMPS circuits offer several advantages over linear power supplies:

-

High efficiency: SMPS circuits can achieve efficiencies of up to 95%, which means less power is wasted as heat, resulting in cooler operation and reduced energy costs.

-

Compact size: The high-frequency operation of SMPS circuits allows for smaller transformers, inductors, and capacitors, resulting in a more compact overall design compared to linear power supplies.

-

Wide input voltage range: SMPS circuits can handle a wide range of input voltages, making them suitable for applications where the input voltage may fluctuate, such as in battery-powered devices or universal power supplies.

-

Flexible output control: By adjusting the switching duty cycle, SMPS circuits can provide precise control over the output voltage or current, enabling features like voltage regulation, current limiting, and programmable output profiles.

Disadvantages of SMPS Circuits

Despite their many advantages, SMPS circuits also have some drawbacks:

-

Electromagnetic interference (EMI): The high-frequency switching in SMPS circuits can generate electromagnetic noise, which can interfere with nearby electronic devices if not properly managed. Careful PCB layout, shielding, and filtering techniques are required to minimize EMI.

-

Complex design: SMPS circuits are more complex than linear power supplies, requiring specialized knowledge in power electronics, control systems, and magnetics. Designing an efficient and reliable SMPS circuit can be challenging and time-consuming.

-

Higher cost: Due to their complexity and the need for specialized components, SMPS circuits can be more expensive than linear power supplies, especially for low-volume applications.

-

Increased ripple: The switching nature of SMPS circuits can result in higher output voltage ripple compared to linear power supplies. Additional filtering may be required to achieve a smooth output voltage.

SMPS Circuit Design Considerations

When designing an SMPS circuit, several key factors must be considered:

-

Input and output specifications: The input voltage range, output voltage, and maximum output current must be clearly defined to select the appropriate SMPS topology and components.

-

Efficiency: Maximizing efficiency is crucial for reducing power losses and heat generation. This involves selecting efficient switching elements, minimizing conduction and switching losses, and optimizing the transformer and inductor designs.

-

Thermal management: Proper thermal management is essential for ensuring the long-term reliability of an SMPS circuit. This includes selecting components with appropriate power ratings, designing effective heat sinking, and ensuring adequate airflow for cooling.

-

EMI suppression: To minimize electromagnetic interference, the SMPS circuit layout should be carefully designed, with attention paid to proper grounding, shielding, and filtering techniques. Compliance with relevant EMC standards may also be required.

-

Feedback and control: The feedback and control circuitry must be designed to ensure stable operation across the entire range of input and output conditions. This may involve selecting appropriate control ICs, designing compensation networks, and implementing protection features like over-voltage and over-current protection.

SMPS Circuit Components

An SMPS circuit typically consists of the following key components:

-

Switching element: The switching element, usually a MOSFET or IGBT, is responsible for the high-frequency switching that enables voltage conversion. The selection of the switching element depends on factors such as the required switching frequency, power handling capability, and efficiency.

-

Transformer: The transformer provides voltage conversion and galvanic isolation between the input and output stages. The transformer design must consider factors such as the turns ratio, core material, and winding techniques to minimize losses and ensure efficient operation.

-

Inductors and capacitors: Inductors and capacitors are used for energy storage and filtering in an SMPS circuit. The selection of these components depends on factors such as the required inductance and capacitance values, current handling capability, and ripple performance.

-

Rectifiers: Rectifiers, such as diodes or synchronous rectifiers, are used to convert the pulsed waveform from the transformer secondary into a DC output voltage. The selection of rectifiers depends on factors such as the required forward voltage drop, reverse recovery time, and efficiency.

-

Control ICs: Control ICs, such as PWM controllers or PFM controllers, are used to generate the switching signals and implement the feedback and control loops. The selection of the control IC depends on factors such as the required control features, accuracy, and compatibility with the chosen SMPS topology.

SMPS Circuit Applications

SMPS circuits are used in a wide range of applications, including:

-

Consumer electronics: SMPS circuits are found in devices such as smartphones, laptops, televisions, and home appliances, where they provide efficient power conversion and help to reduce device size and weight.

-

Industrial equipment: SMPS circuits are used in industrial applications such as motor drives, process control systems, and automation equipment, where they provide reliable and efficient power conversion for a variety of loads.

-

Automotive electronics: SMPS circuits are increasingly used in automotive applications, such as in-vehicle infotainment systems, advanced driver assistance systems (ADAS), and electric vehicle charging systems, where they provide efficient power conversion in a compact and lightweight form factor.

-

Telecommunications: SMPS circuits are used in telecommunications equipment, such as base stations, routers, and switches, where they provide reliable and efficient power conversion for sensitive electronic components.

-

Renewable energy: SMPS circuits are used in renewable energy applications, such as solar inverters and wind turbine controllers, where they provide efficient power conversion and help to maximize energy harvest efficiency.

SMPS Circuit Safety and Regulations

When designing and working with SMPS circuits, it is essential to consider safety and regulatory requirements:

-

Galvanic isolation: Many applications require galvanic isolation between the input and output stages of an SMPS circuit to protect users from electric shock hazards. This is typically achieved using an isolation transformer and appropriate creepage and clearance distances on the PCB.

-

Safety standards: SMPS circuits must comply with relevant safety standards, such as UL, CE, and IEC, depending on the target market and application. These standards specify requirements for electrical safety, fire safety, and mechanical safety.

-

EMC regulations: SMPS circuits must also comply with electromagnetic compatibility (EMC) regulations, such as FCC and CE, to ensure that they do not generate excessive electromagnetic interference and are not susceptible to external interference.

-

Thermal and overcurrent protection: SMPS circuits should incorporate appropriate thermal and overcurrent protection features, such as thermal shutdown and current limiting, to prevent damage to the circuit and connected equipment in the event of a fault condition.

Frequently Asked Questions (FAQ)

-

What is the difference between an SMPS and a linear power supply?

An SMPS uses high-frequency switching and pulse-width modulation to efficiently convert electrical power, while a linear power supply uses a transformer and linear regulators to step down voltage and control output. SMPS circuits are more efficient, compact, and can handle a wider range of input voltages compared to linear power supplies. -

Can an SMPS circuit provide multiple output voltages?

Yes, an SMPS circuit can be designed to provide multiple output voltages by using multiple secondary windings on the transformer and separate rectification and filtering stages for each output. -

What is the typical switching frequency of an SMPS circuit?

The switching frequency of an SMPS circuit can range from a few kilohertz to several megahertz, depending on the specific application and design requirements. Higher switching frequencies allow for smaller transformers and filter components but may increase switching losses and EMI. -

How can I reduce EMI in an SMPS circuit?

To reduce EMI in an SMPS circuit, you can use techniques such as proper PCB layout, grounding, and shielding. Additionally, using snubber circuits, spread-spectrum switching, and EMI filters can help to minimize electromagnetic noise. -

What are the key factors to consider when selecting a switching element for an SMPS circuit?

When selecting a switching element for an SMPS circuit, you should consider factors such as the required switching frequency, power handling capability, efficiency, and cost. MOSFETs and IGBTs are common choices for switching elements, and the specific device selected will depend on the application requirements and design constraints.

Conclusion

SMPS circuits are a critical component in modern electronic devices, providing efficient and compact power conversion solutions for a wide range of applications. By understanding the working principles, types, advantages, and design considerations of SMPS circuits, engineers and enthusiasts can develop efficient and reliable power supply solutions for their projects.

When designing an SMPS circuit, it is essential to consider factors such as input and output specifications, efficiency, thermal management, EMI suppression, and feedback and control. Careful component selection and PCB layout are also crucial for ensuring optimal performance and reliability.

As electronic devices continue to evolve and become more complex, the demand for efficient and compact power supply solutions will only increase. By staying up-to-date with the latest SMPS circuit technologies and design techniques, engineers can meet these challenges and develop innovative power supply solutions for the future.

No responses yet