Introduction to SMD LEDs

Surface-mount device light-emitting diodes (SMD LEDs) have revolutionized the world of electronics, offering a compact, efficient, and versatile lighting solution for a wide range of applications. These tiny luminaries have become an essential component in modern printed circuit board (PCB) designs, providing not only illumination but also contributing to the overall aesthetics and functionality of electronic devices.

In this comprehensive article, we will dive deep into the world of SMD LEDs, exploring their benefits, types, and applications. We will also discuss how incorporating SMD LEDs into your PCB design can optimize your bill of materials (BOM) and streamline your manufacturing process.

The Advantages of SMD LEDs

Compact Size

One of the most significant advantages of SMD LEDs is their compact size. These miniature components typically measure just a few millimeters in length and width, making them ideal for space-constrained PCB designs. Their small footprint allows for higher component density on the board, enabling the creation of more complex and feature-rich devices in smaller form factors.

Energy Efficiency

SMD LEDs are known for their exceptional energy efficiency compared to traditional lighting solutions. They consume significantly less power while producing the same amount of light output, resulting in lower energy consumption and extended battery life in portable devices. This efficiency also translates to reduced heat generation, which can help improve the overall thermal management of your PCB.

Durability and Reliability

Another key benefit of SMD LEDs is their durability and reliability. These solid-state devices have no fragile filaments or glass components, making them resistant to shock, vibration, and extreme temperatures. SMD LEDs have a longer lifespan compared to traditional incandescent bulbs, often lasting tens of thousands of hours without significant degradation in light output.

Wide Range of Colors and Brightness

SMD LEDs are available in a wide spectrum of colors, including red, green, blue, yellow, white, and even multi-color options. This versatility allows designers to incorporate specific colors for different functions, such as status indicators, backlighting, or decorative lighting. Additionally, SMD LEDs offer various brightness levels, enabling precise control over the light intensity to suit specific application requirements.

Types of SMD LEDs

Standard SMD LEDs

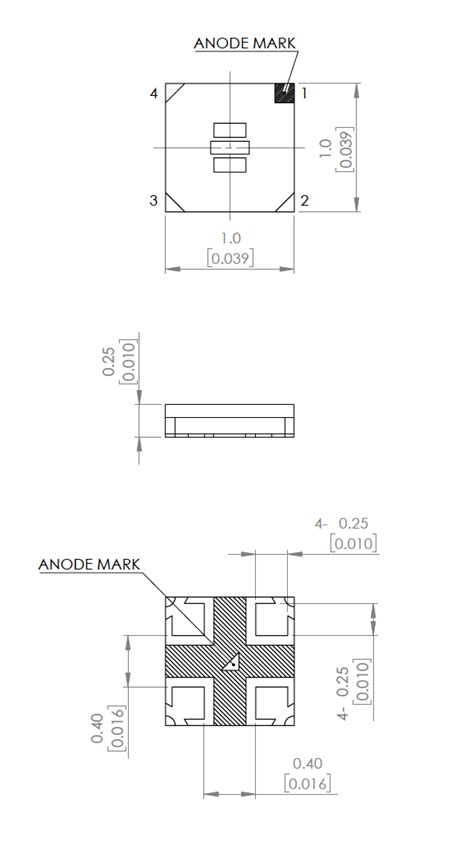

Standard SMD LEDs are the most common type found in PCB designs. They typically come in sizes such as 0603, 0805, and 1206, referring to their dimensions in imperial units (0.06″ x 0.03″, 0.08″ x 0.05″, and 0.12″ x 0.06″, respectively). These LEDs are available in a wide range of colors and are suitable for general-purpose indicating and lighting applications.

High-Power SMD LEDs

High-power SMD LEDs are designed to deliver higher luminous flux compared to standard SMD LEDs. They are often used in applications that require brighter illumination, such as camera flashes, automotive lighting, or general lighting fixtures. High-power SMD LEDs typically have larger packages, such as 3535 or 5050, to accommodate the increased power dissipation and heat generation.

RGB SMD LEDs

RGB SMD LEDs integrate red, green, and blue emitters into a single package, allowing for the generation of a wide range of colors by varying the intensity of each emitter. These LEDs are commonly used in applications that require dynamic color mixing, such as mood lighting, decorative illumination, or status indication. RGB SMD LEDs often come with integrated control circuitry, simplifying the implementation of color-changing effects.

Infrared and Ultraviolet SMD LEDs

Infrared (IR) and ultraviolet (UV) SMD LEDs emit light in the non-visible spectrum. IR SMD LEDs are commonly used in remote control systems, security cameras, and proximity sensors, while UV SMD LEDs find applications in sterilization, curing, and counterfeit detection. These specialized LEDs require specific considerations in PCB design, such as appropriate filtering and protection from harmful wavelengths.

Incorporating SMD LEDs into Your PCB Design

Schematic Design Considerations

When incorporating SMD LEDs into your PCB design, there are several schematic design considerations to keep in mind:

-

Forward Voltage and Current: Each SMD LED has a specific forward voltage (Vf) and forward current (If) rating. Ensure that your design provides the appropriate voltage and current to drive the LEDs without exceeding their maximum ratings.

-

Current-Limiting Resistors: To prevent excessive current from damaging the LEDs, include current-limiting resistors in series with each LED. The resistor value can be calculated based on the LED’s forward voltage, forward current, and the supply voltage.

-

Polarity: SMD LEDs are polarized components, meaning they have a specific anode (+) and cathode (-) orientation. Ensure that the LEDs are connected with the correct polarity in your schematic to avoid reverse bias and potential damage.

-

Multiplexing: If your design requires multiple LEDs to be controlled independently, consider using multiplexing techniques to reduce the number of GPIO pins required. This can be achieved through the use of LED drivers or shift registers.

PCB Layout Considerations

Proper PCB layout is crucial for the optimal performance and reliability of SMD LEDs. Consider the following guidelines when laying out your PCB:

-

Placement: Position the SMD LEDs in a way that minimizes the trace lengths between the LED and its associated components, such as current-limiting resistors and drivers. This helps reduce voltage drops and improves overall efficiency.

-

Thermal Management: High-power SMD LEDs generate significant heat, which can affect their performance and longevity. Incorporate appropriate thermal management techniques, such as using thermal vias, copper pours, or heat sinks, to dissipate heat away from the LEDs.

-

Trace Width: Ensure that the traces connecting the SMD LEDs are wide enough to handle the expected current flow without excessive voltage drop or resistive heating. Use online trace width calculators or consult your PCB manufacturer’s guidelines to determine the appropriate trace widths.

-

Solder Mask and Silkscreen: Apply solder mask around the SMD LED pads to prevent solder bridging and improve the overall aesthetics of the PCB. Use silkscreen labels to indicate the polarity and function of each LED, making it easier for assembly and troubleshooting.

Optimizing Your Bill of Materials with SMD LEDs

Standardization

One of the key strategies for optimizing your bill of materials (BOM) with SMD LEDs is standardization. By selecting a few standard SMD LED packages and colors that can be used across multiple designs, you can reduce the number of unique components in your inventory. This simplifies procurement, minimizes the risk of obsolescence, and allows for bulk purchasing, which can lead to cost savings.

Supplier Selection

Choosing the right supplier for your SMD LEDs is crucial for ensuring a reliable and cost-effective supply chain. Consider factors such as the supplier’s reputation, quality control processes, lead times, and pricing. Establishing strong relationships with trusted suppliers can help you secure favorable terms, such as volume discounts or consignment inventory arrangements.

Inventory Management

Effective inventory management is essential for optimizing your BOM and reducing carrying costs. Implement a robust inventory tracking system that provides real-time visibility into your SMD LED stock levels, lead times, and consumption rates. This information can help you make informed decisions about reorder points, safety stock levels, and order quantities, minimizing the risk of stockouts or excess inventory.

Value Engineering

Value engineering involves identifying opportunities to reduce costs without compromising the functionality or quality of your PCB design. With SMD LEDs, value engineering can involve:

-

Reducing the number of LED colors: Consolidating the color palette to a few essential colors can simplify your BOM and reduce the number of unique LED part numbers.

-

Optimizing LED brightness: Carefully evaluate the required brightness levels for each application and select SMD LEDs with the appropriate luminous intensity. Overspecifying LED brightness can lead to unnecessary costs and power consumption.

-

Exploring alternative suppliers: Continuously monitor the market for new SMD LED suppliers that offer competitive pricing, improved performance, or better lead times. Be open to evaluating and qualifying alternative sources to ensure a robust and cost-effective supply chain.

Frequently Asked Questions (FAQ)

-

Q: What are the most common SMD LED package sizes?

A: The most common SMD LED package sizes are 0603, 0805, and 1206. These sizes refer to the dimensions of the LED package in imperial units (length x width). -

Q: How do I calculate the current-limiting resistor value for an SMD LED?

A: To calculate the current-limiting resistor value, use the following formula: R = (Vs – Vf) / If, where R is the resistor value, Vs is the supply voltage, Vf is the LED’s forward voltage, and If is the LED’s forward current. -

Q: Can I use SMD LEDs for high-power applications?

A: Yes, high-power SMD LEDs are available for applications that require brighter illumination. These LEDs typically come in larger packages, such as 3535 or 5050, to handle the increased power dissipation and heat generation. -

Q: How do I ensure proper thermal management for SMD LEDs?

A: To ensure proper thermal management, consider using thermal vias, copper pours, or heat sinks to dissipate heat away from the SMD LEDs. Also, follow the manufacturer’s guidelines for maximum junction temperature and ensure adequate spacing between LEDs to prevent thermal coupling. -

Q: What are the benefits of using RGB SMD LEDs?

A: RGB SMD LEDs allow for the generation of a wide range of colors by varying the intensity of the red, green, and blue emitters. They are commonly used in applications that require dynamic color mixing, such as mood lighting, decorative illumination, or status indication.

Conclusion

SMD LEDs have become an indispensable component in modern PCB designs, offering a compact, efficient, and versatile lighting solution. By understanding the types, advantages, and design considerations of SMD LEDs, you can effectively incorporate them into your PCB layout and optimize your bill of materials.

Through standardization, supplier selection, inventory management, and value engineering, you can streamline your SMD LED supply chain, reduce costs, and ensure a reliable and efficient production process. As technology continues to advance, SMD LEDs will undoubtedly play an increasingly important role in the world of electronics, illuminating the path to innovative and cost-effective PCB designs.

No responses yet