Introduction to Electronic Circuit Design

Electronic circuit design is the process of creating circuits that perform specific functions using electronic components. It requires a deep understanding of electronics principles, component characteristics, and design techniques. Designing even small electronic circuits demands significant attention to detail in order to ensure proper operation, reliability, and adherence to requirements.

Key Aspects of Circuit Design

Several key aspects must be carefully considered when designing electronic circuits:

Component Selection

Choosing the right components is critical. This includes considering factors like:

- Electrical ratings (voltage, current, power dissipation)

- Performance specifications

- Tolerance and variation

- Physical size and packaging

- Cost and availability

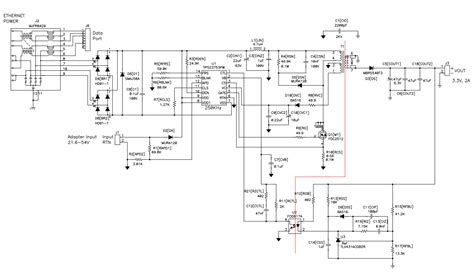

Schematic Capture

The circuit schematic visually represents the components and their interconnections. Best practices for schematics include:

- Using consistent symbols and labeling

- Organizing functionally-related sections

- Minimizing wire crossings for clarity

- Providing reference designators for each component

Simulation and Analysis

Computer-based simulation allows the circuit to be analyzed prior to physical prototyping. Key analyses include:

- DC operating point

- Transient response

- AC small-signal response

- Monte Carlo tolerance analysis

- Worst-case extremes analysis

PCB Layout

The physical layout of the printed circuit board is important for both manufacturability and performance. Layout considerations include:

- Component placement

- Signal routing and interconnects

- Power distribution

- Grounding and shielding

- Thermal management

- Manufacturing rules and constraints

Testing and Verification

Thorough testing is needed to verify the circuit meets requirements. Common tests include:

- Functional testing

- Performance testing

- Stress testing at specification limits

- Environmental testing (temperature, humidity, vibration, etc.)

- Electromagnetic compatibility (EMC) testing

- Reliability testing

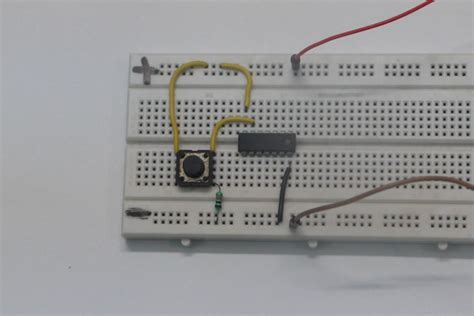

Circuit Design Process

The typical process flow for designing an electronic circuit is:

- Define requirements

- Create block diagram

- Develop schematic

- Perform simulations

- Design PCB layout

- Build prototype

- Conduct testing

- Iterate and refine design

- Release to production

This process involves close collaboration between electrical engineers, PCB designers, test engineers, and other stakeholders. Careful project management is required to coordinate the schedule, budget, and deliverables.

Circuit Design Tools

A variety of software tools are used to aid in the circuit design process:

| Tool Type | Purpose |

|---|---|

| SPICE simulator | Schematic capture and circuit simulation |

| PCB layout | PCB design and layout |

| PDM | Product data management |

| PLM | Product lifecycle management |

The choice of tools depends on the scale and complexity of the design as well as the design team’s preferences and budget. Compatibility and interoperability between tools is an important consideration.

Design for Manufacturing

Designing a circuit that can be efficiently and reliably manufactured requires adhering to good DFM practices:

Design Rules

The circuit must comply with the manufacturing capabilities and rules, such as:

- Minimum trace width and spacing

- Minimum drill size and pad dimensions

- Clearances for safety and isolation

- Panelization and breakout tabs

Component Selection

Components should be chosen with consideration for:

- Automated assembly methods (reflow, wave soldering)

- Pick-and-place machine limitations

- Packaging styles (through-hole, surface-mount)

- Component availability and lifecycle

Testability

The circuit should support in-circuit test and functional test methods:

- Test point access

- Built-in self-test

- Programming and configuration

- Boundary scan

Collaborating closely with the manufacturing team helps ensure a successful transition from design to production.

Analog Circuit Design Techniques

Analog circuits deal with continuous signals and require careful design to maintain signal integrity:

Amplifiers

Amplifier circuits increase the amplitude of small signals. Key parameters include:

- Gain and bandwidth

- Linearity and distortion

- Noise figure

- Input and output impedance

Filters

Filters are used to selectively pass or block certain frequencies. Common filter types are:

- Low-pass

- High-pass

- Band-pass

- Band-stop

Analog-to-Digital Conversion

ADCs convert continuous analog signals into discrete digital values. Important ADC specifications include:

- Resolution (number of bits)

- Sampling rate

- Linearity and monotonicity

- Aperture jitter

Power Regulation

Voltage regulators provide stable power supply voltages to the circuit. Regulator parameters include:

- Output voltage and current

- Line and load regulation

- Dropout voltage

- Efficiency

Analog circuit design requires a good grasp of device physics, feedback control systems, and signal processing theory.

Digital Circuit Design Techniques

Digital circuits operate on discrete binary states, enabling complex logic and data processing:

Boolean Logic

Combinational logic circuits implement Boolean expressions:

- AND, OR, NOT, XOR gates

- Muxes, decoders, adders

- Programmable logic (PLDs, FPGAs)

Sequential Logic

Sequential circuits have memory and their outputs depend on current and previous inputs:

- Flip-flops

- Registers and shift registers

- Counters and state machines

Timing Analysis

The propagation delay through gates and interconnects must be analyzed to ensure correct operation at the desired clock speed:

- Setup and hold time

- Critical path analysis

- Clock skew

- Metastability

Hardware Description Languages

HDLs like Verilog and VHDL allow digital circuits to be defined in code and synthesized into physical implementations. Key constructs include:

- Modules and hierarchy

- Registers and sequential logic

- Dataflow and Boolean expressions

- Test benches

Digital circuits enable powerful data processing but require careful timing design and management of metastability.

Electromagnetic Compatibility

Electronic circuits can both emit and be susceptible to electromagnetic interference (EMI). Proper EMC design minimizes these effects:

Grounding

A low-impedance ground is critical for managing return currents:

- Ground planes

- Star grounds

- Chassis grounds

Shielding

Metallic shields around circuits and cables block radiated EMI:

- Enclosures

- Shield cans and foil

- Shielded cables and connectors

Filtering

Filters suppress conducted EMI entering or leaving the circuit:

- Power supply decoupling

- Feedthrough capacitors

- Common mode chokes

- Ferrites

Circuit Board Layout

The PCB layout significantly impacts EMC performance:

- Component placement

- Signal route shielding

- Avoiding loops and antennas

- Minimizing trace lengths and stubs

Meeting applicable EMC regulatory standards is mandatory for most electronic products.

Thermal Management

Heat generated by electronic components must be properly managed to prevent overheating failures:

Heat Sinks

Heat sinks conduct heat away from hot components and increase surface area for convective cooling. Heat sink parameters include:

- Thermal resistance

- Surface area

- Air flow

Thermal Interface Materials

TIMs fill air gaps between components and heat sinks, reducing thermal resistance:

- Greases

- Pads

- Adhesives

PCB Copper

Heavy copper pours on the PCB help spread heat. Typical copper weights are:

- 0.5 oz to 2 oz for signal layers

- 2 oz or more for ground and power planes

Airflow

Forced airflow from fans increases convective cooling:

- Fan type and size

- Airflow direction

- Vents and ducts

Modeling and measuring component temperatures under worst-case conditions ensures the thermal design is adequate.

Frequently Asked Questions

What education is needed for a career in electronic circuit design?

Most electronic circuit design jobs require at least a bachelor’s degree in electrical engineering or a related field. Additional studies in analog circuits, digital systems, electromagnetic, and semiconductor physics are beneficial. Many designers also pursue graduate degrees to specialize and advance their careers.

What programming languages are used for circuit design?

For digital circuit design, hardware description languages (HDLs) like Verilog and VHDL are commonly used. These allow the behavior of digital systems to be captured in code. General-purpose languages like C and Python are often used for test automation and data analysis scripts.

How much does electronic Circuit design software cost?

The cost of circuit design software varies widely depending on the tool’s capabilities and vendor. Some entry-level or free tools are available, though they may have limited functionality. Full-featured tools used for professional work can range from hundreds to tens of thousands of dollars per license. Many vendors offer time-limited evaluation versions to allow testing before purchasing.

What are the job prospects for electronic circuit designers?

The demand for electronic circuit designers is generally strong and is expected to continue growing. The increasing proliferation of electronics in all industries, along with new applications in areas like IoT, automotive, and medical devices, is driving the need for designers. However, the job market can be competitive, so having a solid educational background and staying current with new technologies is important.

What are some common challenges in electronic circuit design?

Some of the main challenges that electronic circuit designers face include:

- Managing the tradeoffs between cost, performance, and development time

- Integrating analog and digital subsystems and ensuring compatibility

- Modeling and analyzing complex systems with multiple variables

- Keeping up with new components, design tools, and manufacturing processes

- Ensuring reliable operation across all specified environmental conditions

- Meeting safety and regulatory standards for the target markets

Successful designers learn to balance these competing demands through a combination of technical skills, project management, and effective communication with a broad range of stakeholders.

Conclusion

Designing electronic circuits is a challenging and rewarding field that requires a diverse set of technical skills. Even small circuits demand significant attention to detail in order to ensure proper operation and reliability. The process spans initial requirements through component selection, schematic capture, simulation, PCB layout, prototyping, and testing.

Designers must consider numerous factors such as component tolerances, signal integrity, EMC, thermal management, and manufacturability. A variety of software tools are used throughout the process to aid in modeling, analysis, and verification.

Sound engineering practices, project management, and collaboration are essential for successful circuit design. Designers must continuously learn to stay current with advances in components, tools, and applications. With the expanding role of electronics in all industries, the demand for skilled circuit designers is likely to remain strong well into the future.

No responses yet