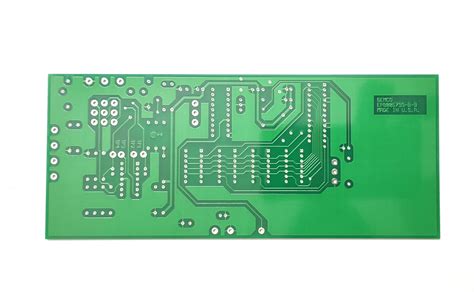

What is a Single-Sided PCB?

A single-sided PCB, also known as a Single-Layer PCB, is a printed circuit board that has conductive traces on only one side of the board. The other side of the board is typically left bare or covered with a solder mask. Single-sided PCBs are the simplest and most cost-effective type of PCB, making them an attractive option for many electronic projects.

Advantages of Single-Sided PCBs

- Cost-effective: Single-sided PCBs are cheaper to manufacture compared to multi-layer PCBs due to their simpler design and fewer materials required.

- Easy to design: Designing a single-sided PCB is relatively straightforward, as there are fewer constraints and considerations compared to multi-layer boards.

- Quick turnaround: Due to their simplicity, single-sided PCBs can be manufactured and assembled faster than more complex boards.

- Suitable for low-complexity circuits: Single-sided PCBs are ideal for projects with simple circuitry and low component density.

Disadvantages of Single-Sided PCBs

- Limited routing options: With only one side available for conductive traces, routing can become challenging for more complex designs.

- Lower component density: Single-sided PCBs have limited space for components, which can restrict the functionality and complexity of the circuit.

- Increased electromagnetic interference (EMI): The lack of a ground plane on single-sided PCBs can lead to higher levels of EMI compared to multi-layer boards.

- Less durable: Single-sided PCBs are more susceptible to damage from environmental factors and mechanical stress compared to multi-layer boards.

How to Design a Single-Sided PCB

Step 1: Create a Schematic

The first step in designing a single-sided PCB is to create a schematic of your circuit. A schematic is a graphical representation of the electrical connections between components. Use a CAD (Computer-Aided Design) software to create your schematic, ensuring that all components and connections are accurately represented.

Step 2: Choose Components

Select the components for your PCB based on the requirements of your project. Consider factors such as power consumption, operating voltage, and package size when choosing components. Ensure that the components are compatible with single-sided PCB design.

Step 3: Place Components

Arrange the components on the PCB layout in a logical and efficient manner. Consider the flow of the circuit and the proximity of related components. Aim to minimize the length of traces and the number of crossovers to simplify routing and reduce EMI.

Step 4: Route Traces

Connect the components using conductive traces. When routing traces on a single-sided PCB, follow these guidelines:

- Keep traces as short and direct as possible

- Avoid sharp angles; use 45-degree angles instead of 90-degree angles

- Maintain appropriate trace width based on the current requirements

- Ensure adequate spacing between traces to prevent short circuits

- Use jumper wires to create crossovers when necessary

Step 5: Add Silk Screen and Solder Mask

Apply a silk screen layer to the PCB to label components, add logos, or include other visual indicators. The silk screen helps with assembly and troubleshooting. Additionally, apply a solder mask to protect the conductive traces and prevent short circuits during soldering.

Step 6: Generate Gerber Files

Once your PCB design is complete, generate Gerber files, which are standard file formats used by PCB manufacturers. Gerber files contain all the necessary information for manufacturing your PCB, including the copper layers, solder mask, silk screen, and drill holes.

How to Save More on Single-Sided PCBs

1. Optimize PCB Design

Efficient PCB design can help reduce manufacturing costs. Consider the following tips:

- Minimize the PCB size: Smaller PCBs require less material and are cheaper to produce.

- Use standard component sizes: Choosing standard component sizes can reduce manufacturing costs and lead times.

- Avoid unnecessary features: Simplify your design by removing non-essential features, such as complex shapes or unnecessary text.

2. Choose the Right Manufacturer

Selecting the right PCB manufacturer can significantly impact your costs. When choosing a manufacturer, consider the following factors:

- Experience and reputation: Look for a manufacturer with a proven track record of producing high-quality PCBs.

- Pricing: Compare prices from multiple manufacturers to ensure you’re getting a competitive rate.

- Minimum order quantity (MOQ): Some manufacturers offer lower prices for larger order quantities. Consider your project requirements and budget when selecting a manufacturer.

3. Order in Bulk

Ordering PCBs in larger quantities can often result in lower unit prices. If your project requires multiple PCBs or if you anticipate future demand, consider placing a bulk order to take advantage of volume discounts.

4. Consider Panelization

Panelization is the process of combining multiple PCB designs onto a single panel for manufacturing. By panelizing your PCBs, you can reduce manufacturing costs and increase production efficiency. This is particularly useful for smaller PCBs or when ordering larger quantities.

5. Use Standard Specifications

Adhering to standard PCB specifications can help reduce manufacturing costs. Some standard specifications to consider include:

- Board thickness: 1.6mm is a common standard thickness for single-sided PCBs.

- Copper weight: 1oz copper is typically sufficient for most single-sided PCB Applications.

- Solder mask color: Green is the most common and cost-effective solder mask color.

By following these guidelines, you can optimize your single-sided PCB design and manufacturing process to save more money.

Frequently Asked Questions (FAQ)

- What is the minimum trace width for a single-sided PCB?

-

The minimum trace width depends on the PCB manufacturer and the specific design requirements. However, a common minimum trace width for single-sided PCBs is 0.2mm (8mil).

-

Can single-sided PCBs be used for high-frequency applications?

-

Single-sided PCBs are generally not recommended for high-frequency applications due to their limited routing options and increased susceptibility to EMI. For high-frequency applications, multi-layer PCBs with proper grounding and shielding are typically used.

-

What is the maximum number of components that can be placed on a single-sided PCB?

-

The maximum number of components that can be placed on a single-sided PCB depends on the size of the board, the size of the components, and the complexity of the circuit. As a general rule, single-sided PCBs are suitable for designs with low to moderate component density.

-

Can single-sided PCBs be used for surface mount components?

-

Yes, single-sided PCBs can be used for surface mount components. However, the placement and routing of surface mount components on a single-sided PCB can be more challenging compared to through-hole components due to the limited space and routing options.

-

What is the typical turnaround time for single-sided PCB manufacturing?

- The turnaround time for single-sided PCB manufacturing varies depending on the manufacturer and the specific project requirements. However, single-sided PCBs generally have shorter turnaround times compared to multi-layer PCBs due to their simpler design and manufacturing process. Typical turnaround times range from 1-2 weeks, but some manufacturers may offer expedited services for faster delivery.

In conclusion, single-sided PCBs offer a cost-effective and efficient solution for simple electronic projects. By understanding the advantages and limitations of single-sided PCBs, optimizing your design, and selecting the right manufacturer, you can save more money while still achieving your project goals. Always consider your specific requirements and budget when making decisions about your PCB design and manufacturing process.

No responses yet