What are Power MOSFETs?

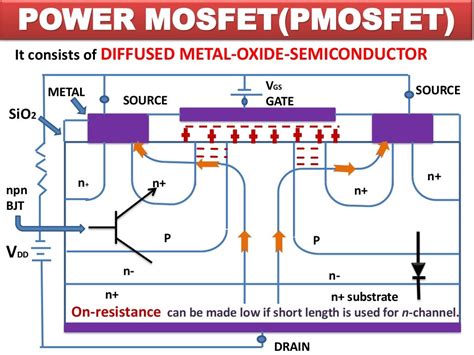

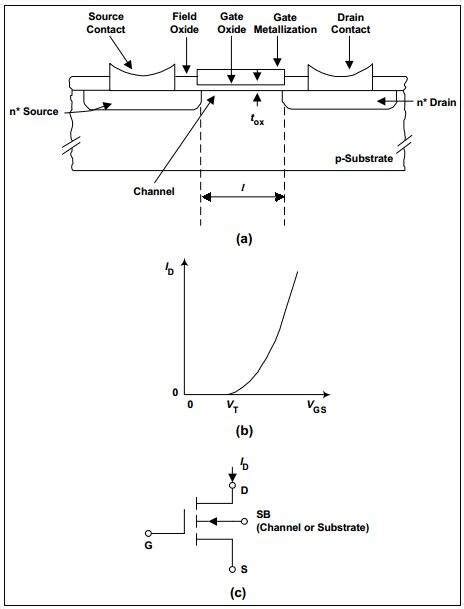

Power MOSFETs are semiconductor devices that consist of three terminals: the gate, source, and drain. They are designed to control the flow of current through a channel between the source and drain terminals by applying a voltage to the gate terminal. When a positive voltage is applied to the gate, it creates an electric field that attracts electrons to the channel, allowing current to flow from the source to the drain. Conversely, when the gate voltage is removed, the channel is closed, and current flow is blocked.

Power MOSFETs are commonly used in various applications, including:

- Switching power supplies

- Motor drives

- Automotive electronics

- Power converters

- Audio amplifiers

They offer several advantages over other types of transistors, such as bipolar junction transistors (BJTs), including:

- High input impedance

- Low on-resistance

- Fast switching speeds

- Low gate drive current requirements

- Ability to handle high currents and voltages

Benefits of Using Power MOSFETs in Series

Using power MOSFETs in series can offer several benefits in certain applications. Some of the main advantages include:

1. Increased Voltage Handling Capability

One of the primary reasons for using power MOSFETs in series is to increase the overall voltage handling capability of the circuit. By connecting multiple MOSFETs in series, the voltage stress is distributed across each device, allowing the circuit to handle higher voltages than a single MOSFET could withstand.

For example, if a single power MOSFET has a maximum drain-to-source voltage rating of 100V, connecting two identical MOSFETs in series would theoretically allow the circuit to handle up to 200V. This is because the voltage drop across each MOSFET would be half of the total voltage applied to the series combination.

2. Improved Current Sharing

Another benefit of using power MOSFETs in series is improved current sharing between the devices. When MOSFETs are connected in parallel, there is a risk of uneven current distribution due to differences in device characteristics, such as on-resistance and threshold voltage. This can lead to one MOSFET carrying more current than the others, potentially causing overheating and premature failure.

By connecting the MOSFETs in series, the current through each device is forced to be equal, as it must flow through all the devices in the series chain. This ensures that the current is evenly distributed among the MOSFETs, reducing the risk of overloading any single device.

3. Reduced Power Dissipation

Using power MOSFETs in series can also help reduce power dissipation in the circuit. When a single MOSFET is used to handle high currents, it may experience significant power dissipation due to its on-resistance. This can lead to increased heat generation and reduced efficiency.

By distributing the current among multiple MOSFETs in series, the power dissipation is spread across the devices, reducing the thermal stress on each individual MOSFET. This can help improve the overall efficiency of the circuit and extend the lifetime of the components.

Challenges of Using Power MOSFETs in Series

While using power MOSFETs in series can offer several benefits, there are also some challenges and considerations to keep in mind:

1. Voltage Balancing

One of the main challenges when using power MOSFETs in series is ensuring proper voltage balancing across the devices. Due to manufacturing variations and differences in device characteristics, the voltage drop across each MOSFET may not be perfectly equal. This can lead to one device experiencing a higher voltage stress than the others, potentially exceeding its maximum rating and causing failure.

To address this issue, voltage balancing techniques are often employed. Some common methods include:

- Using matched MOSFETs with similar characteristics

- Implementing voltage balancing resistors or capacitors across each MOSFET

- Employing active voltage balancing circuits, such as gate drive transformers or feedback control loops

| Voltage Balancing Technique | Advantages | Disadvantages |

|---|---|---|

| Matched MOSFETs | Simple implementation, no additional components | Limited availability, higher cost |

| Balancing Resistors/Capacitors | Easy to implement, low cost | Power dissipation, reduced efficiency |

| Active Balancing Circuits | Precise voltage balancing, improved efficiency | Increased complexity, higher cost |

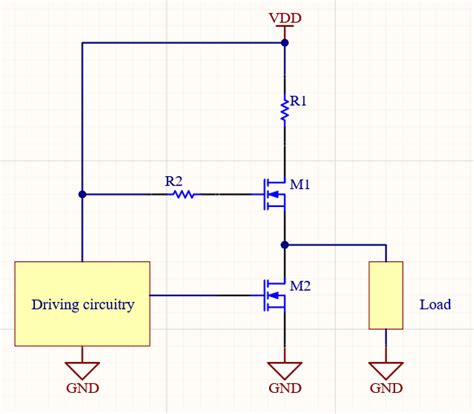

2. Switching Synchronization

Another challenge when using power MOSFETs in series is ensuring synchronized switching of the devices. If the MOSFETs do not turn on and off simultaneously, it can lead to uneven voltage distribution and increased stress on individual devices.

To achieve synchronized switching, the gate drive signals for each MOSFET must be carefully designed and timed. This can be accomplished using techniques such as:

- Using a single gate drive circuit with matched propagation delays to each MOSFET

- Employing gate drive transformers or coupled inductors to provide isolated and synchronized gate signals

- Implementing digital control techniques, such as field-programmable gate arrays (FPGAs) or microcontrollers, to generate precise gate drive signals

3. Parasitic Effects

When using power MOSFETs in series, parasitic effects such as stray inductances and capacitances can have a significant impact on the circuit’s performance. These parasitic elements can cause voltage spikes, ringing, and uneven voltage distribution during switching transitions.

To minimize the impact of parasitic effects, careful circuit layout and design techniques must be employed. Some strategies include:

- Minimizing the loop area between the MOSFETs and their associated components

- Using low-inductance bus bars or printed circuit board (PCB) traces for high-current paths

- Implementing snubber circuits or voltage clamping devices to suppress voltage spikes and ringing

- Optimizing the gate drive circuit to minimize the impact of gate-to-drain capacitance

Applications of Power MOSFETs in Series

Power MOSFETs in series are commonly used in various high-voltage and high-power applications, such as:

1. High-Voltage Power Supplies

In high-voltage power supply designs, such as those used in X-ray machines, lasers, and particle accelerators, power MOSFETs in series are often employed to handle the high voltage requirements. By distributing the voltage stress across multiple devices, the power supply can generate and regulate voltages in the range of several kilovolts.

2. Motor Drives

In motor drive applications, power MOSFETs in series can be used to control the speed and torque of high-voltage motors, such as those found in electric vehicles and industrial machinery. By using series-connected MOSFETs, the drive circuit can handle the high voltages required to control the motor while ensuring efficient and reliable operation.

3. Pulse Power Systems

Pulse power systems, such as those used in radar, sonar, and particle beam applications, often employ power MOSFETs in series to generate high-voltage, high-current pulses. By using multiple MOSFETs in series, the pulse power system can achieve the required voltage and current levels while minimizing the stress on individual devices.

Frequently Asked Questions (FAQ)

-

Q: Can any type of power MOSFET be used in series?

A: While most power MOSFETs can be used in series, it is recommended to use devices with similar characteristics, such as on-resistance and threshold voltage, to ensure optimal performance and reliability. -

Q: How many power MOSFETs can be connected in series?

A: The number of power MOSFETs that can be connected in series depends on the specific application and the voltage and current requirements. In theory, there is no limit to the number of devices that can be used, but practical considerations such as voltage balancing and switching synchronization may limit the practical number of devices. -

Q: What is the purpose of voltage balancing when using power MOSFETs in series?

A: Voltage balancing ensures that the voltage stress is evenly distributed across each MOSFET in the series chain. This prevents any single device from experiencing a voltage that exceeds its maximum rating, which could lead to device failure. -

Q: How can synchronized switching be achieved when using power MOSFETs in series?

A: Synchronized switching can be achieved by using techniques such as matched gate drive circuits, gate drive transformers, or digital control methods. These techniques ensure that the gate drive signals for each MOSFET are precisely timed and synchronized, minimizing voltage stress and ensuring reliable operation. -

Q: Are there any additional considerations when using power MOSFETs in series in high-frequency applications?

A: Yes, in high-frequency applications, parasitic effects such as stray inductances and capacitances can have a more significant impact on the circuit’s performance. Careful circuit layout and design techniques, such as minimizing loop areas and using snubber circuits, must be employed to mitigate these effects and ensure optimal performance.

Conclusion

Using power MOSFETs in series can offer several benefits, including increased voltage handling capability, improved current sharing, and reduced power dissipation. However, it is essential to consider the challenges and design considerations, such as voltage balancing, switching synchronization, and parasitic effects, to ensure optimal performance and reliability.

By understanding the benefits and challenges of using power MOSFETs in series and employing appropriate design techniques, engineers and designers can leverage the advantages of these devices in various high-voltage and high-power applications, such as power supplies, motor drives, and pulse power systems.

As with any power electronics design, careful analysis, simulation, and testing are crucial to validate the performance and reliability of circuits using power MOSFETs in series. By following best practices and considering the specific requirements of the application, designers can successfully implement power MOSFETs in series to achieve efficient, reliable, and high-performance power electronic systems.

No responses yet