What are Sensor Circuits?

A sensor circuit is an electronic circuit that incorporates one or more sensors to detect and measure physical quantities and convert them into electrical signals. These signals can then be processed, analyzed, and used to control other devices or systems. Sensor circuits play a crucial role in bridging the gap between the physical world and the digital domain, allowing electronic devices to interact with their environment.

Key Components of Sensor Circuits

Sensor circuits typically consist of the following key components:

- Sensor: The primary component that detects and measures the physical quantity of interest.

- Signal Conditioning Circuitry: Electronics that process and amplify the sensor’s output signal to make it suitable for further processing.

- Analog-to-Digital Converter (ADC): Converts the analog sensor signal into a digital format for use by digital systems.

- Microcontroller or Processor: Processes the digital sensor data and performs necessary computations or control functions.

Types of Sensors

There are numerous types of sensors available, each designed to detect and measure specific physical quantities. Some of the most common types of sensors include:

Temperature Sensors

Temperature sensors measure the amount of heat energy in a system or environment. They are widely used in applications such as:

- Environmental monitoring

- HVAC systems

- Industrial process control

- Medical devices

Common types of temperature sensors include:

- Thermistors

- Resistance Temperature Detectors (RTDs)

- Thermocouples

- Semiconductor temperature sensors

| Sensor Type | Operating Principle | Temperature Range | Accuracy |

|---|---|---|---|

| Thermistor | Resistance change | -90°C to 130°C | ±0.1°C |

| RTD | Resistance change | -200°C to 850°C | ±0.1°C |

| Thermocouple | Voltage generation | -270°C to 1300°C | ±0.5°C |

| Semiconductor | Voltage change | -55°C to 150°C | ±0.5°C |

Pressure Sensors

Pressure sensors measure the force applied to a surface per unit area. They are used in various applications, such as:

- Automotive systems (e.g., tire pressure monitoring)

- Industrial process control

- Medical devices (e.g., blood pressure monitoring)

- Aerospace and aviation

Common types of pressure sensors include:

- Piezoresistive pressure sensors

- Capacitive pressure sensors

- Piezoelectric pressure sensors

- Optical pressure sensors

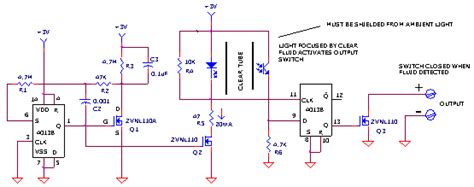

Light Sensors

Light sensors detect the presence or intensity of light in a given environment. They are used in applications such as:

- Automatic lighting control

- Camera systems

- Optical communication

- Ambient light sensing in displays

Common types of light sensors include:

- Photoresistors (LDRs)

- Photodiodes

- Phototransistors

- Ambient light sensors

Motion Sensors

Motion sensors detect the presence, movement, or acceleration of objects. They are used in various applications, such as:

- Security systems

- Automotive safety systems

- Gaming controllers

- Fitness trackers

Common types of motion sensors include:

- Passive Infrared (PIR) sensors

- Ultrasonic sensors

- Accelerometers

- Gyroscopes

Signal Conditioning in Sensor Circuits

The output signals from sensors often require conditioning before they can be effectively processed by digital systems. Signal conditioning circuitry is designed to perform the following functions:

- Amplification: Increasing the strength of the sensor’s output signal to a level suitable for further processing.

- Filtering: Removing unwanted noise or interference from the sensor signal.

- Linearization: Correcting non-linear sensor outputs to achieve a linear relationship between the measured physical quantity and the electrical signal.

- Offset and Gain Adjustment: Calibrating the sensor output to account for variations in sensor characteristics and ensuring accurate measurements.

Some common signal conditioning techniques include:

- Operational amplifier (op-amp) based circuits

- Instrumentation amplifiers

- Active filters

- Wheatstone bridge circuits for resistive sensors

- Charge amplifiers for piezoelectric sensors

Interfacing Sensors with Microcontrollers

To effectively use sensors in electronic systems, it is essential to interface them with microcontrollers or processors that can process the sensor data and perform necessary control functions. The following steps are involved in interfacing sensors with microcontrollers:

- Selecting an appropriate ADC: Choose an ADC with sufficient resolution and sampling rate to accurately capture the sensor signal.

- Configuring the ADC: Set up the ADC’s input range, sampling rate, and other parameters to match the sensor’s output characteristics.

- Establishing communication: Use an appropriate communication protocol (e.g., I2C, SPI, UART) to transfer sensor data from the ADC to the microcontroller.

- Processing sensor data: Implement software routines to process the sensor data, perform necessary computations, and generate control signals or output data.

Some popular microcontroller platforms for sensor interfacing include:

- Arduino

- Raspberry Pi

- STM32

- ESP32

Sensor Fusion and Advanced Techniques

In some applications, using a single sensor may not provide sufficient information or accuracy. Sensor fusion techniques combine data from multiple sensors to achieve more robust and reliable measurements. Some common sensor fusion techniques include:

- Kalman filtering: A mathematical algorithm that combines data from multiple sensors to estimate the state of a system, considering the uncertainty of each sensor’s measurements.

- Complementary filtering: A technique that combines data from sensors with complementary characteristics (e.g., gyroscope and accelerometer) to obtain a more accurate estimate of orientation or position.

- Bayesian inference: A probabilistic approach that uses prior knowledge and sensor observations to estimate the state of a system.

Applications of Sensor Circuits

Sensor circuits find applications in a wide range of industries and domains, including:

- Automotive: Engine management, safety systems, navigation, and climate control.

- Industrial automation: Process control, quality monitoring, and predictive maintenance.

- Consumer electronics: Smartphones, wearables, gaming devices, and home automation.

- Healthcare: Medical devices, patient monitoring, and diagnostic equipment.

- Environmental monitoring: Weather stations, air and water quality monitoring, and precision agriculture.

- Robotics and autonomous systems: Navigation, obstacle detection, and control of robotic systems.

Frequently Asked Questions (FAQ)

- What is the difference between active and passive sensors?

-

Active sensors require an external power source to operate and actively emit energy (e.g., ultrasonic sensors, radar), while passive sensors do not require power and rely on detecting energy from the environment (e.g., thermistors, photoresistors).

-

How do I choose the right sensor for my application?

-

Consider factors such as the physical quantity to be measured, the required accuracy and resolution, the operating environment, and the available budget. Consult sensor datasheets and application notes to determine the most suitable sensor for your specific needs.

-

What is the role of an ADC in a sensor circuit?

-

An ADC converts the analog output signal from a sensor into a digital format that can be processed by a microcontroller or processor. The ADC’s resolution and sampling rate determine the accuracy and speed of the digital conversion process.

-

How can I reduce noise in my sensor readings?

-

Implement appropriate signal conditioning techniques such as filtering, shielding, and proper grounding. Use decoupling capacitors to reduce power supply noise, and consider using differential signaling for improved noise immunity. Employ software techniques like averaging and digital filtering to further enhance signal quality.

-

What are some common challenges in designing sensor circuits?

- Some challenges include selecting the appropriate sensor and signal conditioning components, ensuring proper calibration and compensation for environmental factors, managing power consumption, and designing robust and reliable circuits that can operate in harsh environments. Careful design, testing, and validation are essential to overcome these challenges and create effective sensor circuits.

Conclusion

Sensor circuits play a vital role in enabling electronic devices and systems to interact with the physical world. By understanding the fundamentals of sensor circuits, the different types of sensors available, and the techniques for signal conditioning and interfacing with microcontrollers, designers can create innovative and effective solutions for a wide range of applications.

As technology continues to advance, the demand for more sophisticated and intelligent sensor systems will only grow. By staying up-to-date with the latest developments in sensor technology and circuit design techniques, engineers and developers can continue to push the boundaries of what is possible and create new opportunities for sensing and control in various domains.

No responses yet