Introduction to Schematic Review

A schematic review is a crucial step in the design process of electronic circuits and systems. It involves thoroughly examining the schematic diagram to ensure that the design is accurate, complete, and compliant with the project requirements and industry standards. A comprehensive schematic review checklist helps designers and reviewers to systematically evaluate the schematic and identify potential issues before proceeding to the PCB layout and fabrication stages.

Importance of Schematic Review

Conducting a thorough schematic review is essential for several reasons:

- Error detection: A schematic review helps identify and correct design errors, such as incorrect component values, missing connections, or wrong pin assignments, early in the design process.

- Design optimization: During the review, designers can identify opportunities to optimize the circuit design, such as reducing component count, improving signal integrity, or enhancing power efficiency.

- Cost savings: Identifying and rectifying issues during the schematic review phase can save significant time and cost compared to discovering problems later in the PCB layout or fabrication stages.

- Collaboration and communication: A schematic review facilitates collaboration among team members and stakeholders, ensuring that everyone has a clear understanding of the design intent and requirements.

- Documentation: The schematic review process helps create accurate and up-to-date documentation, which is essential for future reference, maintenance, and troubleshooting.

Schematic Review Checklist

To conduct a comprehensive schematic review, follow this checklist:

1. Design Requirements

- [ ] Review the project requirements and specifications

- [ ] Ensure that the schematic meets the functional and performance requirements

- [ ] Verify that the schematic is consistent with the block diagram and other system-level documents

2. Component Selection

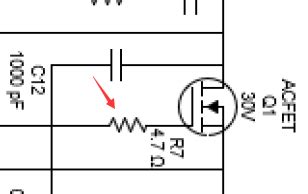

- [ ] Check that the components are appropriate for the application and meet the required specifications (e.g., voltage rating, power dissipation, tolerance)

- [ ] Verify that the components are available and not obsolete

- [ ] Ensure that the component footprints are correct and match the manufacturer’s recommendations

3. Power Supply

- [ ] Verify that the power supply is properly designed and rated for the circuit requirements

- [ ] Check for proper power supply decoupling and bypassing

- [ ] Ensure that the power supply sequencing is correct (if applicable)

4. Grounding and Shielding

- [ ] Verify that the grounding scheme is appropriate for the circuit (e.g., single-point, multi-point, or hybrid grounding)

- [ ] Check for proper ground plane usage and connection

- [ ] Ensure that sensitive signals are properly shielded and separated from noisy signals

5. Signal Integrity

- [ ] Verify that the signal paths are as short as possible and have appropriate terminations

- [ ] Check for proper impedance matching and controlled impedance traces (if applicable)

- [ ] Ensure that the signal levels and noise margins are within acceptable limits

6. Electromagnetic Compatibility (EMC)

- [ ] Verify that the circuit is designed to minimize electromagnetic interference (EMI) and susceptibility

- [ ] Check for proper filtering, shielding, and grounding techniques to mitigate EMC issues

- [ ] Ensure that the circuit complies with relevant EMC standards and regulations

7. Connectivity and Interfaces

- [ ] Verify that all the required connections are present and correct

- [ ] Check for proper connector pinouts and orientations

- [ ] Ensure that the interfaces (e.g., I2C, SPI, USB) are properly implemented and meet the required specifications

8. Testability and Debugging

- [ ] Verify that the circuit includes appropriate test points and debugging interfaces

- [ ] Check for proper labeling and identification of test points and connectors

- [ ] Ensure that the circuit can be easily tested and debugged during development and production

9. Documentation and Readability

- [ ] Ensure that the schematic is well-organized, readable, and follows industry standards (e.g., IEEE 315)

- [ ] Verify that the component designators, net names, and labels are consistent and meaningful

- [ ] Check that the schematic includes appropriate notes, comments, and revision history

10. Design for Manufacturing (DFM)

- [ ] Verify that the schematic is designed with manufacturability in mind

- [ ] Check for proper component spacing, orientation, and placement

- [ ] Ensure that the schematic complies with the PCB manufacturer’s design rules and guidelines

Schematic Review Process

The schematic review process typically involves the following steps:

- Preparation: Gather all the necessary documents, such as project requirements, datasheets, and reference designs.

- Individual review: Each reviewer independently examines the schematic using the checklist as a guide.

- Collaboration: Reviewers discuss their findings, share insights, and resolve any discrepancies or concerns.

- Issue tracking: Document and track all the issues identified during the review process using a spreadsheet or a dedicated issue tracking tool.

- Design updates: The designer addresses the identified issues and updates the schematic accordingly.

- Re-review: Repeat the review process until all the issues are resolved and the schematic is approved for PCB layout.

Best Practices for Schematic Review

To ensure an effective and efficient schematic review process, consider the following best practices:

- Establish clear guidelines: Develop and maintain a comprehensive schematic review checklist that is tailored to your organization’s needs and standards.

- Foster a collaborative environment: Encourage open communication and teamwork among reviewers, designers, and stakeholders to facilitate a thorough and constructive review process.

- Allocate sufficient time: Provide reviewers with adequate time to thoroughly examine the schematic and document their findings.

- Use automation tools: Leverage electronic design automation (EDA) tools that offer automated schematic checks and design rule checks (DRC) to complement the manual review process.

- Continuously improve: Regularly update and refine the schematic review checklist based on lessons learned, new technologies, and evolving industry standards.

Schematic Review Tools

Several EDA tools offer features that can aid in the schematic review process, such as:

- Altium Designer: Provides a built-in design rule checker and a schematic comparison tool to identify differences between schematic revisions.

- Cadence OrCAD: Offers a design rule checker and a schematic design analyzer to identify potential issues and optimize the design.

- Mentor Graphics PADS: Includes a design rule checker and a schematic navigator to facilitate efficient schematic review and navigation.

- KiCad: An open-source EDA suite that offers a schematic editor with built-in electrical rules check (ERC) and design rule check (DRC) capabilities.

Schematic Review and Version Control

Integrating schematic review with version control systems (e.g., Git, SVN) can greatly enhance the design collaboration and iteration process. By using version control, teams can:

- Track changes: Maintain a complete history of schematic revisions, allowing designers to easily identify and revert changes if needed.

- Collaborate effectively: Enable multiple designers to work on the same schematic simultaneously, with the ability to merge changes and resolve conflicts.

- Enhance accountability: Associate each change with a specific designer, making it easier to identify the person responsible for a particular modification.

- Streamline design reviews: Use version control features like pull requests and code reviews to facilitate schematic reviews and gather feedback from the team.

Common Schematic Review Issues

During a schematic review, some common issues that may be identified include:

- Incorrect component values: Components with wrong values or tolerances can lead to circuit malfunction or performance degradation.

- Missing or incorrect connections: Incomplete or incorrect connections can result in open circuits, short circuits, or signal integrity issues.

- Inappropriately sized components: Components that are undersized or oversized for the application can cause reliability issues or inefficient use of board space.

- Inconsistent naming conventions: Inconsistent or unclear naming of components, nets, and labels can lead to confusion and errors during PCB layout and assembly.

- Insufficient power supply decoupling: Inadequate decoupling can result in power supply noise, which can adversely affect circuit performance and signal integrity.

- Lack of proper grounding: Improper grounding schemes can cause ground loops, noise coupling, and EMC issues.

- Violation of design rules: Schematic designs that violate the PCB manufacturer’s design rules can lead to fabrication issues and increased costs.

Schematic Review and Compliance

In addition to ensuring the technical correctness of the schematic, the review process should also consider compliance with relevant industry standards and regulations, such as:

- IPC standards: IPC (Association Connecting Electronics Industries) publishes various standards related to PCB design, fabrication, and assembly, such as IPC-2612 (Sectional Requirements for Electronic Diagramming Documentation) and IPC-2221 (Generic Standard on Printed Board Design).

- IEEE standards: The Institute of Electrical and Electronics Engineers (IEEE) publishes standards that cover various aspects of electronic design, such as IEEE 315 (Graphic Symbols for Electrical and Electronics Diagrams) and IEEE 1149.1 (Standard Test Access Port and Boundary-Scan Architecture).

- Safety standards: Depending on the application and target market, the schematic design may need to comply with safety standards such as UL (Underwriters Laboratories), CE (Conformité Européenne), or CSA (Canadian Standards Association).

- Environmental regulations: The schematic design should also consider environmental regulations, such as RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals), which restrict the use of certain hazardous materials in electronic products.

Schematic Review and PCB Layout

The schematic review process is closely tied to the subsequent PCB layout phase. A well-reviewed schematic can greatly simplify the PCB layout process and minimize the need for layout-driven schematic changes. Some key considerations for the schematic review in relation to PCB layout include:

- Component placement: Ensure that the schematic is organized in a way that facilitates efficient component placement on the PCB, with related components grouped together and signal paths optimized for minimum length and crosstalk.

- Signal integrity: Verify that the schematic design takes into account signal integrity considerations, such as proper termination, impedance matching, and crosstalk prevention, which will be critical during PCB layout.

- Power distribution: Review the schematic to ensure that the power distribution network is properly designed, with adequate decoupling and minimal voltage drop, to simplify the PCB power plane design.

- Footprint selection: Confirm that the selected component footprints are appropriate for the PCB manufacturing process and the assembly method (e.g., surface mount or through-hole), and that they match the actual component dimensions.

Conclusion

A comprehensive schematic review is an essential step in the electronic design process, ensuring that the schematic is accurate, complete, and compliant with project requirements and industry standards. By following a systematic schematic review checklist and adopting best practices, designers can identify and address issues early in the design cycle, saving time, cost, and effort in the later stages of PCB layout and fabrication.

Regular schematic reviews also promote collaboration, knowledge sharing, and continuous improvement within the design team. By integrating schematic review with version control systems and leveraging EDA tools, teams can streamline the review process and maintain a clear history of design changes.

Ultimately, a well-executed schematic review process lays the foundation for a successful PCB design, leading to higher-quality products, faster time-to-market, and improved customer satisfaction.

Frequently Asked Questions (FAQ)

- What is a schematic review?

A schematic review is a thorough examination of a schematic diagram to ensure that the design is accurate, complete, and compliant with project requirements and industry standards. - Why is a schematic review important?

A schematic review is important because it helps identify and correct design errors early in the design process, saving time, cost, and effort in the later stages of PCB layout and fabrication. It also promotes collaboration, knowledge sharing, and continuous improvement within the design team. - What are the key areas covered in a schematic review checklist?

A typical schematic review checklist covers areas such as design requirements, component selection, power supply, grounding and shielding, signal integrity, electromagnetic compatibility, connectivity and interfaces, testability and debugging, documentation and readability, and design for manufacturing. - What are some common issues identified during a schematic review?

Common issues identified during a schematic review include incorrect component values, missing or incorrect connections, inappropriately sized components, inconsistent naming conventions, insufficient power supply decoupling, lack of proper grounding, and violation of design rules. - How can EDA tools assist in the schematic review process?

EDA tools can assist in the schematic review process by providing features such as built-in design rule checkers, schematic comparison tools, and automated schematic checks to complement the manual review process. Some popular EDA tools that offer these features include Altium Designer, Cadence OrCAD, Mentor Graphics PADS, and KiCad.

No responses yet