What is a Gerber File?

A Gerber file is a standard file format used in the printed circuit board (PCB) industry to describe the printed circuit board images copper layers, solder mask, legend, drill holes, etc. It is a 2D binary vector image file format: all the images are defined as draws and arcs.

The Gerber file format was originally developed by the Gerber Systems Corp., a division of Gerber Scientific, founded by Joseph Gerber. The Gerber file is now considered the de facto standard used by PCB fabrication houses.

Gerber File Extensions

Gerber files come in a variety of file extensions, including:

| Extension | Description |

|---|---|

| .GBR | Generic extension, drawings, copper layers, masks |

| .GKO | Board outline |

| .GTP | Top paste |

| .GTP | Top paste |

| .GBP | Bottom paste |

| .GTO | Top overlay |

| .GBO | Bottom overlay |

| .GTS | Top solder mask |

| .GBS | Bottom solder mask |

| .GM1 | Mechanical layer 1 |

| .GD1 | Drill/rout layer |

Role of Gerber Files in PCB Manufacturing Process

The PCB manufacturing process involves several steps, and Gerber files play a crucial role in many of these steps. Here’s an overview of the PCB manufacturing process and how Gerber files are used:

PCB Design

The PCB design process involves creating a schematic diagram and a PCB layout using PCB design software. Once the design is complete, the PCB design software generates Gerber files for each layer of the PCB, including the copper layers, solder mask, silk screen, and drill holes.

Gerber File Generation

The Gerber file generation process involves converting the PCB design into a format that can be read by the PCB fabrication equipment. The PCB design software generates a separate Gerber file for each layer of the PCB, and these files are sent to the PCB fabrication house.

PCB Fabrication

The PCB fabrication process involves several steps, including:

-

Film Printing: The Gerber files are used to create photographic films for each layer of the PCB. These films are used to transfer the PCB design onto the copper-clad laminate.

-

Etching: The photographic films are used to selectively etch away the unwanted copper from the laminate, leaving behind the desired copper traces.

-

Drilling: The drill file, which is also generated from the Gerber files, is used to drill holes in the PCB for component placement and vias.

-

Solder Mask Application: The solder mask layer, which is generated from the Gerber files, is applied to the PCB to protect the copper traces and prevent short circuits.

-

Silk Screen Printing: The silk screen layer, which is generated from the Gerber files, is used to print text and symbols on the PCB for component identification and assembly instructions.

PCB Assembly

Once the PCB fabrication process is complete, the PCB is ready for assembly. The Gerber files are used to generate assembly drawings and pick-and-place files, which are used to guide the automated assembly equipment in placing components on the PCB.

Importance of Gerber Files in PCB Manufacturing

Gerber files are essential to the PCB manufacturing process because they provide a standardized way to describe the PCB design to the fabrication house. Without Gerber files, it would be very difficult to manufacture PCBs consistently and with high quality.

Here are some reasons why Gerber files are so important:

-

Standardization: Gerber files provide a standardized format for describing PCB designs, which makes it easier for PCB fabrication houses to work with designs from different sources.

-

Accuracy: Gerber files allow for very precise description of PCB features, down to the micrometer level. This level of accuracy is essential for manufacturing high-quality PCBs.

-

Automation: Gerber files can be read by automated PCB fabrication equipment, which allows for faster and more efficient manufacturing processes.

-

Quality Control: Gerber files provide a way to verify that the PCB design meets the necessary specifications before manufacturing begins. This helps to catch errors early and avoid costly rework.

Common Issues with Gerber Files

While Gerber files are essential to the PCB manufacturing process, there are some common issues that can arise:

-

Incompatible File Formats: Not all PCB design software generates Gerber files in the same format. It’s important to ensure that the Gerber files are compatible with the fabrication house’s equipment.

-

Missing Layers: If a Gerber file is missing a layer, such as the solder mask or silk screen layer, it can cause problems during manufacturing.

-

Incorrect Aperture Sizes: The aperture sizes specified in the Gerber files must match the actual sizes used in the PCB design. Incorrect aperture sizes can cause issues with etching and drilling.

-

Incorrect Units: Gerber files can be generated in either metric or imperial units. It’s important to ensure that the units match the fabrication house’s requirements.

Best Practices for Working with Gerber Files

To ensure that Gerber files are generated correctly and can be used effectively in the PCB manufacturing process, here are some best practices to follow:

-

Use a reputable PCB design software: Choose a PCB design software that generates Gerber files in a compatible format with your fabrication house’s equipment.

-

Double-check the Gerber files: Before sending the Gerber files to the fabrication house, double-check that all layers are included and that the aperture sizes and units are correct.

-

Communicate with the fabrication house: Work closely with the fabrication house to ensure that they have all the necessary information to manufacture the PCB correctly.

-

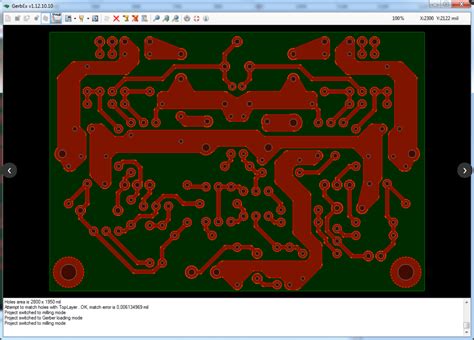

Use a Gerber file viewer: Use a Gerber file viewer to visually inspect the Gerber files before sending them to the fabrication house. This can help catch errors early.

Gerber File Formats

There are several different Gerber file formats, each with its own advantages and disadvantages. Here’s an overview of the most common Gerber file formats:

Standard Gerber RS-274-D

The Standard Gerber RS-274-D format is the most basic Gerber file format. It uses a simple ASCII format to describe the PCB features, and it has some limitations in terms of the types of features it can describe.

Extended Gerber RS-274X

The Extended Gerber RS-274X format is an improved version of the Standard Gerber format. It includes additional commands for describing more complex PCB features, such as filled areas and arcs.

Gerber X2

The Gerber X2 format is the most advanced Gerber file format. It includes additional metadata that describes the PCB features in more detail, such as the layer type and polarity. This makes it easier for PCB fabrication houses to interpret the Gerber files and reduces the risk of errors.

FAQ

- What software can be used to view Gerber files?

There are several software options available for viewing Gerber files, including: - GerbView (free)

- ViewMate (free)

- CAM350 (paid)

-

Valor (paid)

-

Can Gerber files be edited?

Gerber files are not meant to be edited directly. If changes need to be made to the PCB design, it’s best to make the changes in the PCB design software and then regenerate the Gerber files. -

What happens if a Gerber file is missing a layer?

If a Gerber file is missing a layer, such as the solder mask or silk screen layer, it can cause problems during manufacturing. The PCB fabrication house may need to contact the designer to obtain the missing files, which can delay the manufacturing process. -

How do I ensure that my Gerber files are compatible with my fabrication house’s equipment?

The best way to ensure compatibility is to communicate with the fabrication house and provide them with the necessary information about your Gerber files, such as the file format and units used. Many fabrication houses also provide guidelines or templates for generating Gerber files that are compatible with their equipment. -

Can Gerber files be used for other manufacturing processes besides PCBs?

While Gerber files are primarily used in the PCB industry, they can also be used for other manufacturing processes that involve 2D vector images, such as laser cutting or engraving. However, the specific requirements for these processes may differ from those for PCB manufacturing.

Conclusion

Gerber files play a crucial role in the PCB manufacturing process, providing a standardized way to describe PCB designs to fabrication houses. By following best practices for generating and working with Gerber files, designers can ensure that their PCBs are manufactured correctly and with high quality. As PCB designs continue to become more complex, the importance of Gerber files will only continue to grow in the future.

No responses yet