Introduction to ISU Petasys

ISU Petasys is a leading multilayer manufacturing company that specializes in the production of high-quality printed circuit boards (PCBs). With their state-of-the-art technology and experienced team of professionals, ISU Petasys has established itself as a reliable partner for businesses seeking successful PCB implementation.

Company Overview

| Company Name | ISU Petasys |

|---|---|

| Industry | Electronics Manufacturing |

| Specialty | Multilayer PCB Production |

| Founded | 1999 |

| Headquarters | South Korea |

ISU Petasys was founded in 1999 with the mission to provide innovative solutions for the electronics industry. Over the years, the company has expanded its operations and has become a trusted name in the field of PCB manufacturing.

Products and Services

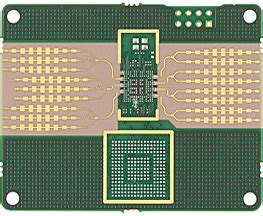

ISU Petasys offers a wide range of PCB products and services to cater to the diverse needs of their clients. Some of their key offerings include:

- Multilayer PCBs

- High-density interconnect (HDI) PCBs

- Flexible PCBs

- Rigid-flex PCBs

- PCB assembly services

The company’s expertise in multilayer PCB production has enabled them to serve various industries, including:

- Automotive

- Telecommunications

- Consumer electronics

- Medical devices

- Aerospace and defense

The Importance of Multilayer PCBs in Modern Electronics

What are Multilayer PCBs?

Multilayer PCBs are printed circuit boards that consist of multiple layers of conductive material, typically copper, separated by insulating layers. These layers are interconnected through vias, which are small holes drilled through the board and plated with conductive material.

Advantages of Multilayer PCBs

Multilayer PCBs offer several advantages over traditional single-layer PCBs:

- Increased circuit density: Multilayer PCBs allow for more complex circuits to be designed in a smaller space, enabling the creation of compact and highly functional electronic devices.

- Improved signal integrity: The use of multiple layers helps to reduce electromagnetic interference (EMI) and crosstalk, ensuring cleaner and more reliable signal transmission.

- Enhanced thermal management: The multilayer structure allows for better heat dissipation, which is crucial for high-performance electronic components.

- Reduced manufacturing costs: By consolidating multiple circuits onto a single board, multilayer PCBs can help to reduce overall manufacturing costs and improve production efficiency.

Applications of Multilayer PCBs

Multilayer PCBs are used in a wide range of electronic applications, including:

- Smartphones and tablets

- Computers and laptops

- Automotive electronic systems

- Medical devices and equipment

- Industrial control systems

- Telecommunications infrastructure

ISU Petasys’ Approach to Multilayer PCB Manufacturing

Advanced Technology and Equipment

ISU Petasys invests in the latest technology and equipment to ensure the highest quality standards in their multilayer PCB production process. Some of the key technologies employed by the company include:

- Laser drilling for precise via formation

- Automated optical inspection (AOI) for defect detection

- Computer numerical control (CNC) routing for accurate board shaping

- Impedance control for consistent electrical performance

Quality Control and Testing

To maintain the highest levels of quality, ISU Petasys implements stringent quality control measures throughout the manufacturing process. This includes:

- Incoming material inspection

- In-process quality checks

- Final inspection and testing

- Burn-in testing for critical applications

The company also adheres to international quality standards, such as ISO 9001 and IPC Class 2 and 3, to ensure that their products meet or exceed customer expectations.

Customization and Prototyping Services

ISU Petasys understands that every customer has unique requirements when it comes to PCB design and functionality. To address this, the company offers customization and prototyping services to help clients bring their ideas to life.

The company’s experienced design team works closely with customers to understand their specific needs and develop tailored PCB solutions. Rapid prototyping capabilities allow for quick iteration and refinement of designs, ensuring that the final product meets the desired specifications.

Successful PCB Implementation with ISU Petasys

Case Studies

ISU Petasys has a proven track record of successful PCB implementation across various industries. Here are a few notable case studies:

Automotive Infotainment System

- Challenge: A leading automotive manufacturer required a compact and reliable PCB solution for their next-generation infotainment system.

- Solution: ISU Petasys developed a high-density multilayer PCB with advanced signal integrity features, enabling seamless integration of multiple functions within a limited space.

- Result: The client successfully launched their infotainment system, which received positive reviews for its performance and reliability.

Medical Device PCB

- Challenge: A medical device company needed a PCB that could withstand harsh sterilization processes while maintaining high precision and reliability.

- Solution: ISU Petasys designed a multilayer PCB using special materials and coatings to ensure compatibility with sterilization methods and long-term durability.

- Result: The medical device achieved regulatory approval and has been successfully deployed in healthcare facilities worldwide.

Customer Support and Collaboration

ISU Petasys believes in building strong, long-term relationships with their customers. The company offers comprehensive customer support services, including:

- Technical consultation and guidance

- Design review and optimization

- Supply chain management

- After-sales support and maintenance

By working closely with customers throughout the PCB implementation process, ISU Petasys ensures that projects are completed on time, within budget, and to the highest quality standards.

Future Trends and Innovations in Multilayer PCB Technology

Miniaturization and High-Density Packaging

As electronic devices continue to shrink in size while increasing in functionality, the demand for miniaturized and high-density PCBs will continue to grow. ISU Petasys is investing in advanced technologies, such as ultra-fine line patterning and embedded components, to enable the production of even more compact and complex multilayer PCBs.

Sustainable and Eco-Friendly Manufacturing

With growing concerns over environmental sustainability, there is a growing trend towards eco-friendly PCB manufacturing processes. ISU Petasys is committed to reducing its environmental footprint by implementing green initiatives, such as:

- Using lead-free and halogen-free materials

- Implementing waste reduction and recycling programs

- Adopting energy-efficient manufacturing processes

By embracing sustainable practices, ISU Petasys aims to contribute to a greener future for the electronics industry.

Industry 4.0 and Smart Manufacturing

The advent of Industry 4.0 and the Internet of Things (IoT) is transforming the manufacturing landscape. ISU Petasys is leveraging these technologies to create smarter and more efficient PCB production processes.

By integrating sensors, data analytics, and automation into their manufacturing systems, the company can optimize production, reduce waste, and improve overall quality control. This not only benefits ISU Petasys but also enables them to deliver better value to their customers.

Frequently Asked Questions (FAQ)

- What sets ISU Petasys apart from other PCB manufacturers?

- ISU Petasys differentiates itself through its focus on multilayer PCB technology, advanced manufacturing capabilities, and commitment to customer success. The company’s experienced team, state-of-the-art equipment, and rigorous quality control processes ensure the delivery of high-quality PCBs that meet the most demanding requirements.

- How does ISU Petasys ensure the reliability and durability of their PCBs?

- ISU Petasys employs a multi-faceted approach to ensure the reliability and durability of their PCBs. This includes the use of high-quality materials, advanced manufacturing techniques, and thorough testing and inspection procedures. The company also offers customized solutions, such as special coatings and reinforcements, to enhance the durability of PCBs in harsh operating environments.

- What industries does ISU Petasys serve?

- ISU Petasys serves a wide range of industries, including automotive, telecommunications, consumer electronics, medical devices, aerospace, and defense. The company’s versatile multilayer PCB technology enables them to cater to the diverse needs of these industries, from high-volume consumer products to mission-critical applications.

- How does ISU Petasys support customers throughout the PCB implementation process?

- ISU Petasys offers comprehensive customer support services to ensure successful PCB implementation. This includes technical consultation, design review and optimization, supply chain management, and after-sales support. The company’s experienced team works closely with customers to understand their specific requirements and provide tailored solutions that meet their needs.

- What is ISU Petasys’ approach to sustainability and eco-friendly manufacturing?

- ISU Petasys is committed to sustainable and eco-friendly manufacturing practices. The company implements green initiatives, such as using lead-free and halogen-free materials, reducing waste, and adopting energy-efficient processes. By embracing sustainability, ISU Petasys aims to minimize its environmental impact while delivering high-quality PCBs to its customers.

Conclusion

ISU Petasys has established itself as a leader in multilayer PCB manufacturing, providing innovative solutions for businesses across various industries. With their advanced technology, experienced team, and commitment to quality, ISU Petasys is well-positioned to help companies realize successful PCB implementation.

As the electronics industry continues to evolve, ISU Petasys remains at the forefront of innovation, investing in cutting-edge technologies and sustainable practices to meet the ever-changing needs of their customers. By partnering with ISU Petasys, businesses can leverage the company’s expertise and capabilities to create high-performance, reliable, and cost-effective PCB solutions that drive their success in the market.

No responses yet