Introduction

In the world of high-frequency electronics, the choice of printed circuit board (PCB) material plays a crucial role in determining the performance and reliability of devices operating in the millimeter-wave (mmWave) frequency range. As the demand for mmWave applications continues to grow, engineers and designers must carefully consider the properties and characteristics of various RF PCB materials to ensure optimal system performance.

This article provides an in-depth comparison of popular RF PCB materials suitable for mmWave devices, focusing on their dielectric properties, loss tangent, thermal stability, and manufacturing considerations. By understanding the strengths and limitations of each material, designers can make informed decisions when selecting the most appropriate substrate for their specific application.

Understanding mmWave Frequencies and Their Challenges

Millimeter-wave frequencies, typically defined as the range between 30 GHz and 300 GHz, offer several advantages for modern wireless communication systems and sensing applications. These high frequencies enable wider bandwidths, higher data rates, and improved spatial resolution compared to lower frequency bands.

However, designing PCBs for mmWave devices comes with its own set of challenges:

-

Higher losses: As frequencies increase, the dielectric and conductor losses in PCB materials become more significant, leading to signal attenuation and degraded performance.

-

Reduced wavelengths: mmWave frequencies have shorter wavelengths, making PCB traces more susceptible to signal integrity issues such as reflections, crosstalk, and radiation.

-

Stringent manufacturing requirements: The smaller feature sizes and tighter tolerances required for mmWave PCBs demand advanced manufacturing processes and strict quality control measures.

To address these challenges, RF PCB materials for mmWave devices must exhibit low dielectric loss, excellent thermal stability, and consistent electrical properties across the desired frequency range.

Key Properties of RF PCB Materials

When evaluating RF PCB materials for mmWave applications, several key properties should be considered:

Dielectric Constant (Dk)

The dielectric constant, also known as the relative permittivity (εr), is a measure of a material’s ability to store electrical energy in an electric field. A lower dielectric constant is generally preferred for mmWave PCBs as it allows for wider trace widths and spacing, reducing conductor losses and improving manufacturability.

Dissipation Factor (Df) or Loss Tangent (tanδ)

The dissipation factor or loss tangent quantifies the amount of energy dissipated in a dielectric material when subjected to an alternating electric field. A lower loss tangent is desirable for mmWave applications to minimize signal attenuation and maintain high-quality factor (Q) in resonant structures.

Thermal Stability

RF PCB materials must maintain their electrical properties over the expected operating temperature range of the device. Materials with low thermal coefficient of dielectric constant (TCDk) and thermal coefficient of dissipation factor (TCDf) are preferred to ensure consistent performance across temperature variations.

Moisture Absorption

Moisture absorption can significantly impact the electrical properties of PCB materials, leading to changes in dielectric constant and increased losses. Materials with low moisture absorption rates are essential for maintaining stable performance in humid environments.

Mechanical Properties

The mechanical properties of RF PCB materials, such as dimensional stability, coefficient of thermal expansion (CTE), and flexural strength, are important considerations for reliability and compatibility with assembly processes.

Popular RF PCB Materials for mmWave Devices

Several RF PCB materials have been developed specifically for mmWave applications, offering a range of properties to suit different design requirements. Some popular options include:

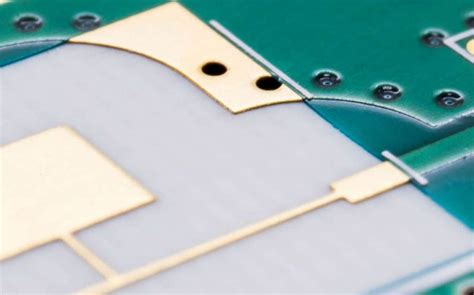

PTFE (Polytetrafluoroethylene) Laminates

PTFE-based laminates, such as Rogers RT/duroid® and Taconic TLY, are well-established materials for high-frequency applications. They offer excellent electrical properties, including low dielectric constant (2.1-2.3) and low loss tangent (0.0009-0.0020), making them suitable for mmWave designs. These materials also exhibit good thermal stability and low moisture absorption.

However, PTFE laminates can be challenging to process due to their softness and tendency to cold-flow, requiring specialized fabrication techniques. They also have a higher cost compared to other materials.

Hydrocarbon Ceramic Laminates

Hydrocarbon ceramic laminates, such as Rogers RO4000® series and Taconic RF-35, combine a woven glass fabric with a ceramic-filled hydrocarbon resin system. These materials offer a balance of good electrical properties (Dk: 3.3-3.7, Df: 0.0025-0.0037) and improved mechanical stability compared to PTFE laminates.

Hydrocarbon ceramic laminates are easier to process and are compatible with standard PCB manufacturing techniques, making them a popular choice for cost-sensitive mmWave applications.

Low-Temperature Co-fired Ceramic (LTCC)

LTCC is a multilayer ceramic substrate technology that allows for the integration of passive components, such as resistors, capacitors, and inductors, within the substrate itself. This enables the creation of highly compact and integrated mmWave modules.

LTCC materials, such as DuPont GreenTape™ and Ferro A6M, offer low dielectric loss (tanδ: 0.001-0.002), good thermal conductivity, and a stable dielectric constant (6-8) over a wide frequency range. However, LTCC requires specialized design and manufacturing processes, and the higher dielectric constant may not be suitable for all mmWave applications.

Liquid Crystal Polymer (LCP)

LCP is a unique material that combines the benefits of both ceramic and polymer substrates. It offers excellent electrical properties (Dk: 2.9-3.1, Df: 0.002-0.004), low moisture absorption, and a near-hermetic seal due to its low permeability.

LCP’s low CTE and good thermal stability make it an attractive option for mmWave applications with strict dimensional requirements. However, LCP’s anisotropic nature requires careful design considerations, and its cost is relatively high compared to other materials.

Comparison Table

| Material | Dielectric Constant (Dk) | Dissipation Factor (Df) | Thermal Stability | Moisture Absorption | Processing Ease |

|---|---|---|---|---|---|

| PTFE Laminates | 2.1-2.3 | 0.0009-0.0020 | Excellent | Low | Challenging |

| Hydrocarbon Ceramic | 3.3-3.7 | 0.0025-0.0037 | Good | Low | Easier |

| LTCC | 6-8 | 0.001-0.002 | Good | Low | Specialized |

| LCP | 2.9-3.1 | 0.002-0.004 | Excellent | Very Low | Moderate |

Selecting the Right RF PCB Material for mmWave Devices

Choosing the most suitable RF PCB material for a specific mmWave application involves careful consideration of the device’s requirements, including:

- Frequency range and bandwidth

- Required electrical performance (loss, phase stability, etc.)

- Environmental conditions (temperature, humidity)

- Mechanical constraints (size, weight, flexibility)

- Integration and assembly requirements

- Cost and manufacturing considerations

By weighing these factors and comparing the properties of available materials, designers can make an informed decision that balances performance, reliability, and cost-effectiveness.

Frequently Asked Questions (FAQ)

1. What is the most important property to consider when selecting an RF PCB material for mmWave devices?

The most important property depends on the specific application, but generally, low dielectric loss (low Df or tanδ) is crucial for maintaining signal integrity and minimizing attenuation at mmWave frequencies.

2. Can FR-4 PCB material be used for mmWave applications?

Standard FR-4 PCB material is not suitable for mmWave applications due to its high dielectric loss and poor thermal stability at high frequencies. Specialized RF PCB materials with low loss and good thermal properties are required for optimal mmWave performance.

3. What is the impact of moisture absorption on RF PCB materials?

Moisture absorption can cause changes in the dielectric constant and increase dielectric loss, leading to degraded performance and potential reliability issues. Materials with low moisture absorption rates are preferred for mmWave applications, especially in humid environments.

4. How does the dielectric constant affect the design of mmWave PCBs?

A lower dielectric constant allows for wider trace widths and spacing, which can help reduce conductor losses and improve manufacturability. However, materials with higher dielectric constants may be necessary for certain applications, such as miniaturization or impedance matching.

5. Are there any cost-effective RF PCB materials suitable for mmWave devices?

Hydrocarbon ceramic laminates, such as Rogers RO4000® series, offer a good balance of electrical performance and cost-effectiveness for many mmWave applications. They are also easier to process compared to PTFE laminates, making them a popular choice for cost-sensitive designs.

Conclusion

Selecting the appropriate RF PCB material is crucial for the success of mmWave device designs. By understanding the key properties and trade-offs of various materials, designers can make informed decisions that optimize performance, reliability, and cost.

PTFE laminates, hydrocarbon ceramic laminates, LTCC, and LCP are among the most popular RF PCB materials for mmWave applications, each offering unique advantages and challenges. Careful consideration of the device’s requirements and operating conditions should guide the material selection process.

As mmWave technologies continue to advance, new materials and manufacturing techniques are likely to emerge, providing designers with even more options for creating high-performance, reliable, and cost-effective PCBs for the next generation of wireless communication and sensing applications.

No responses yet