Introduction to Resistive Touch Technology

Resistive touch technology is one of the most widely used touch sensing technologies in various applications, from smartphones and tablets to industrial control panels and medical devices. It offers a simple, cost-effective, and reliable way to detect and respond to touch inputs on a screen or surface.

What is a Resistive Touch Sensor?

A resistive touch sensor is a device that detects touch by measuring the change in electrical resistance between two conductive layers when they are pressed together. It consists of two transparent conductors, typically made of indium tin oxide (ITO), separated by a thin space. When a user touches the screen, the two layers make contact, and the sensor detects the change in resistance at the point of contact.

Advantages of Resistive Touch Sensors

Resistive touch sensors offer several advantages over other touch sensing technologies:

- Low cost: Resistive touch sensors are relatively inexpensive to manufacture compared to other touch technologies like capacitive or infrared.

- Durability: The simple construction of resistive touch sensors makes them highly durable and resistant to wear and tear.

- Versatility: Resistive touch sensors can work with any type of touch input, including bare fingers, gloves, or a stylus.

- Accuracy: Resistive touch sensors can provide high accuracy and resolution, making them suitable for applications that require precise touch input.

How Resistive Touch Sensors Work

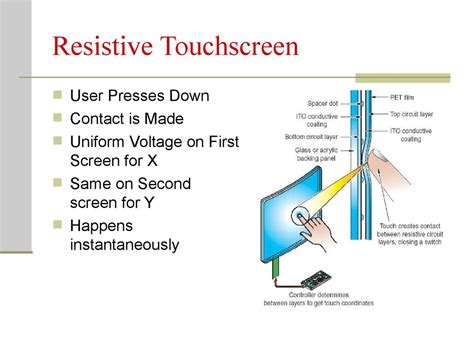

The Structure of a Resistive Touch Sensor

A typical resistive touch sensor consists of the following components:

- Top layer: A flexible, transparent conductor (usually ITO) is coated on a polyester film.

- Spacer dots: Small, transparent dots are printed on the top layer to maintain a uniform gap between the top and bottom layers.

- Bottom layer: A rigid, transparent conductor (also ITO) is coated on a glass or acrylic substrate.

- Conductive bars: Conductive bars are printed along the edges of the top and bottom layers to provide electrical connections.

The Touch Detection Process

When a user touches the screen, the following steps occur:

- The top layer flexes and makes contact with the bottom layer at the point of touch.

- The electrical resistance between the top and bottom layers changes at the point of contact.

- The conductive bars on the edges of the layers detect the change in resistance.

- The controller circuit connected to the conductive bars calculates the X and Y coordinates of the touch point based on the resistance values.

Calculating Touch Coordinates

The controller circuit uses a voltage divider method to calculate the touch coordinates. It applies a voltage gradient across one layer (e.g., top layer for X-axis) while keeping the other layer (bottom layer for X-axis) at a constant voltage. The voltage at the point of contact is proportional to its position along the axis. The process is then repeated for the other axis (Y-axis) by swapping the roles of the layers.

The touch coordinates can be calculated using the following formulas:

X = (Vx – Vmin) / (Vmax – Vmin) * Width

Y = (Vy – Vmin) / (Vmax – Vmin) * Height

Where:

– Vx and Vy are the voltages measured at the point of contact for the X and Y axes, respectively.

– Vmin and Vmax are the minimum and maximum voltages applied across the layers.

– Width and Height are the dimensions of the touch screen.

Types of Resistive Touch Sensors

There are two main types of resistive touch sensors:

4-Wire Resistive Touch Sensors

In a 4-wire resistive touch sensor, the top and bottom layers each have two conductive bars (one on each edge) for voltage application and measurement. The controller circuit alternates between the layers to determine the X and Y coordinates of the touch point.

Advantages:

– Simple construction and lower cost compared to 5-wire sensors.

– Faster response time due to fewer switching operations.

Disadvantages:

– Lower durability due to the repeated flexing of the top layer.

– Reduced accuracy and linearity compared to 5-wire sensors.

5-Wire Resistive Touch Sensors

A 5-wire resistive touch sensor has an additional conductive bar on the bottom layer, which acts as a voltage reference. This configuration allows the controller to measure the touch coordinates using only the top layer, while the bottom layer provides a stable reference voltage.

Advantages:

– Higher durability and longer lifespan due to reduced flexing of the top layer.

– Better accuracy and linearity compared to 4-wire sensors.

Disadvantages:

– Slightly higher cost and complexity compared to 4-wire sensors.

– Slower response time due to additional switching operations.

Applications of Resistive Touch Sensors

Resistive touch sensors are used in a wide range of applications, including:

Consumer Electronics

- Smartphones and tablets (particularly in low-cost devices)

- Digital cameras and camcorders

- E-book readers

- Portable gaming devices

Industrial and Commercial Applications

- Point-of-sale (POS) terminals

- Industrial control panels and HMIs

- Medical devices and equipment

- Automotive touchscreens (e.g., infotainment systems, navigation displays)

- Kiosks and information displays

Comparison with Other Touch Technologies

Resistive touch sensors compete with other touch sensing technologies, such as capacitive and infrared. The following table compares the key characteristics of these technologies:

| Technology | Resistive | Capacitive | Infrared |

|---|---|---|---|

| Activation | Pressure | Conductive touch | Interruption of light beams |

| Multi-touch | Limited | Extensive | Limited |

| Accuracy | High | High | Moderate |

| Durability | Moderate | High | High |

| Cost | Low | Moderate to High | High |

| Visibility | Good | Excellent | Good |

| Glove operation | Yes | No | Yes |

Challenges and Limitations of Resistive Touch Sensors

Despite their advantages, resistive touch sensors also have some challenges and limitations:

Wear and Tear

The repeated flexing of the top layer can lead to wear and tear over time, reducing the sensor’s sensitivity and accuracy. This is particularly true for 4-wire sensors, which rely on the top layer for both X and Y coordinate measurements.

Reduced Visibility

The multiple layers of a resistive touch sensor can reduce the overall transparency of the screen, affecting the display quality and visibility, especially in outdoor or bright light conditions.

Limited Multi-touch Capability

Resistive touch sensors have limited multi-touch capability compared to capacitive sensors. They can typically detect only one touch point at a time, although some advanced controllers can support two-point touch detection.

Future Developments and Trends

As touch technology continues to evolve, researchers and manufacturers are working on improving resistive touch sensors and developing new variations:

Hybrid Touch Sensors

Hybrid touch sensors combine resistive and capacitive technologies to offer the benefits of both. For example, a resistive-capacitive hybrid sensor can provide the accuracy and durability of a resistive sensor while enabling multi-touch functionality through capacitive sensing.

Pressure-sensitive Resistive Touch Sensors

Researchers are developing resistive touch sensors that can detect not only the position but also the pressure of a touch. This can enable new forms of user interaction, such as pressure-based gestures and variable-force input.

Transparent Conductive Materials

The development of new transparent conductive materials, such as silver nanowires, graphene, and conductive polymers, can potentially replace ITO in resistive touch sensors. These materials offer better optical and electrical properties, flexibility, and cost-effectiveness.

Frequently Asked Questions (FAQ)

-

Q: Are resistive touch sensors suitable for outdoor use?

A: Yes, resistive touch sensors can work well in outdoor environments because they are not affected by moisture, dust, or gloves. However, the reduced visibility due to multiple layers may affect the display quality in bright sunlight. -

Q: Can resistive touch sensors detect multiple touch points simultaneously?

A: Most resistive touch sensors can detect only one touch point at a time. However, some advanced controllers can support two-point touch detection, enabling limited multi-touch functionality. -

Q: How do resistive touch sensors compare to capacitive sensors in terms of cost?

A: Resistive touch sensors are generally less expensive to manufacture than capacitive sensors, making them a cost-effective choice for many applications. However, the cost difference has been narrowing as capacitive technology becomes more widespread. -

Q: What is the typical lifespan of a resistive touch sensor?

A: The lifespan of a resistive touch sensor depends on factors such as the type (4-wire or 5-wire), usage frequency, and environmental conditions. On average, a well-designed resistive touch sensor can last for 1-3 million touches or 3-5 years of regular use. -

Q: Can resistive touch sensors be used with gloves or a stylus?

A: Yes, one of the main advantages of resistive touch sensors is their ability to work with any type of touch input, including gloved fingers or a stylus. This makes them suitable for applications where users may need to wear gloves, such as industrial or medical settings.

Conclusion

Resistive touch sensors are a reliable, cost-effective, and versatile solution for many touch-based applications. By understanding their working principles, advantages, and limitations, designers and engineers can make informed decisions when integrating touch functionality into their products.

As touch technology continues to advance, resistive touch sensors are likely to remain a key player, alongside capacitive and other emerging technologies. With ongoing research and development, we can expect to see further improvements in the performance, durability, and capabilities of resistive touch sensors in the future.

No responses yet