Introduction to Radar PCB Technology

Radar PCB, or Printed Circuit Board, is a specialized electronic circuit designed for detecting and processing radio frequency (RF) signals. This technology has revolutionized the field of detection and automation by enabling the creation of compact, efficient, and highly sensitive radar systems. Radar PCBs are used in a wide range of applications, from automotive safety and security to industrial automation and environmental monitoring.

What is a Radar PCB?

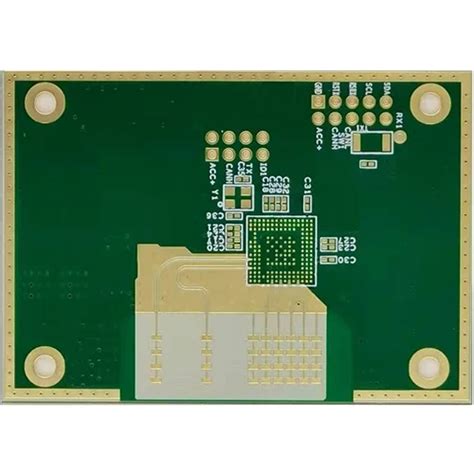

A Radar PCB is a multi-layered circuit board that incorporates various electronic components, such as antennas, amplifiers, filters, and signal processing units, to transmit and receive RF signals. The PCB acts as a substrate for these components, providing a stable and organized platform for their interconnection and operation.

The main function of a Radar PCB is to generate and transmit RF signals, which are then reflected by objects in the environment. The reflected signals are then received by the PCB’s antenna and processed by the onboard electronic components to determine the presence, distance, and velocity of the detected objects.

Key Components of a Radar PCB

A typical Radar PCB consists of the following key components:

-

Antenna: The antenna is responsible for transmitting and receiving RF signals. It can be integrated directly onto the PCB or connected externally, depending on the specific application and design requirements.

-

Transceiver: The transceiver is a combined transmitter and receiver unit that generates and processes RF signals. It typically includes an oscillator, amplifier, and mixer circuits.

-

Signal Processing Unit: This component is responsible for analyzing the received RF signals and extracting relevant information, such as distance, velocity, and direction of the detected objects. It often includes a microcontroller or digital signal processor (DSP) for complex signal processing tasks.

-

Power Management Unit: The power management unit ensures a stable and regulated power supply to all the electronic components on the Radar PCB. It may include voltage regulators, power filters, and protection circuits.

Advantages of Radar PCB Technology

Radar PCB technology offers several advantages over traditional radar systems, making it an attractive choice for various applications:

Compact Size and Low Power Consumption

One of the main advantages of Radar PCB technology is its ability to integrate all the necessary electronic components onto a single, compact circuit board. This miniaturization enables the creation of small, lightweight, and portable radar systems that can be easily integrated into various devices and vehicles.

Moreover, Radar PCBs are designed to operate with low power consumption, making them suitable for battery-powered applications and energy-efficient systems.

High Sensitivity and Accuracy

Radar PCBs are equipped with advanced signal processing capabilities that enable them to detect and track objects with high sensitivity and accuracy. By employing sophisticated algorithms and signal processing techniques, Radar PCBs can filter out noise and interference, resulting in clearer and more reliable detection results.

Cost-Effectiveness and Scalability

Compared to traditional radar systems, which often require bulky and expensive components, Radar PCBs offer a cost-effective solution for mass production and deployment. The standardized manufacturing processes and the use of readily available electronic components make Radar PCBs more affordable and accessible to a wider range of industries and applications.

Furthermore, Radar PCB technology is highly scalable, allowing for the development of customized solutions tailored to specific application requirements. The modular nature of PCB design enables easy integration of additional features and functionalities, such as communication interfaces, data storage, and user interfaces.

Applications of Radar PCB Technology

Radar PCB technology finds applications in various domains, ranging from automotive and industrial sectors to consumer electronics and environmental monitoring. Some of the key applications include:

Automotive Safety and Advanced Driver Assistance Systems (ADAS)

Radar PCBs are widely used in the automotive industry for implementing advanced safety features and driver assistance systems. Some common applications include:

-

Adaptive Cruise Control (ACC): Radar PCBs are used to detect the distance and velocity of the vehicle in front, enabling the system to automatically adjust the speed and maintain a safe following distance.

-

Blind Spot Detection (BSD): Radar PCBs mounted on the side mirrors or rear bumper can detect vehicles in the blind spots and alert the driver to potential collisions during lane changes.

-

Automatic Emergency Braking (AEB): By continuously monitoring the road ahead, Radar PCBs can detect imminent collisions and trigger the braking system to prevent or mitigate accidents.

-

Parking Assistance: Radar PCBs can be used to detect obstacles and guide the driver during parking maneuvers, providing audio and visual alerts to prevent collisions.

Industrial Automation and Robotics

Radar PCB technology is increasingly being adopted in industrial automation and robotics applications for object detection, navigation, and collision avoidance. Some examples include:

-

Material Handling: Radar PCBs can be integrated into automated guided vehicles (AGVs) and mobile robots to detect obstacles and navigate safely within warehouses and manufacturing facilities.

-

Process Monitoring: Radar PCBs can be used to monitor the level of liquids, solids, and granular materials in tanks, silos, and conveyors, enabling real-time process control and optimization.

-

Quality Control: By incorporating Radar PCBs into inspection systems, manufacturers can detect defects, irregularities, and foreign objects in products, ensuring high quality and reducing waste.

Security and Surveillance

Radar PCB technology offers a reliable and cost-effective solution for security and surveillance applications, such as:

-

Intrusion Detection: Radar PCBs can be used to detect unauthorized entry into restricted areas, triggering alarms and alerting security personnel.

-

Perimeter Monitoring: By deploying a network of Radar PCBs along the perimeter of a facility, security teams can detect and track the movement of people and vehicles, preventing unauthorized access and ensuring the safety of the premises.

-

Drone Detection: Radar PCBs can be used to detect and track the presence of drones in restricted airspaces, helping to prevent potential security breaches and collisions with manned aircraft.

Environmental Monitoring and Weather Forecasting

Radar PCB technology has significant applications in environmental monitoring and weather forecasting, enabling the collection of real-time data on various atmospheric and oceanic parameters. Some examples include:

-

Precipitation Monitoring: Radar PCBs can be used to measure the intensity, distribution, and movement of rainfall, snowfall, and hail, providing valuable data for flood forecasting and water resource management.

-

Wind Profiling: By analyzing the Doppler shift of the reflected RF signals, Radar PCBs can measure the speed and direction of wind at various altitudes, aiding in weather forecasting and renewable energy resource assessment.

-

Ocean Monitoring: Radar PCBs can be used to measure ocean surface currents, wave heights, and sea states, providing crucial information for maritime navigation, coastal protection, and climate research.

Challenges and Future Developments in Radar PCB Technology

Despite the numerous advantages and applications of Radar PCB technology, there are still some challenges and areas for future development:

Interference and Clutter Mitigation

One of the main challenges in Radar PCB technology is the presence of interference and clutter in the received RF signals. Interference can be caused by other electronic devices operating in the same frequency range, while clutter refers to unwanted reflections from the environment, such as buildings, trees, and terrain.

To mitigate these issues, researchers are developing advanced signal processing algorithms and antenna design techniques, such as adaptive beamforming, polarimetric filtering, and multi-static radar configurations. These approaches aim to enhance the signal-to-noise ratio and improve the overall detection performance of Radar PCBs.

Integration with Other Sensing Modalities

Another area of future development is the integration of Radar PCB technology with other sensing modalities, such as cameras, lidar, and ultrasonic sensors. By fusing data from multiple sensors, the overall perception and decision-making capabilities of the system can be significantly enhanced.

For example, in automotive applications, the combination of Radar PCBs with cameras can provide a more comprehensive understanding of the surrounding environment, enabling more accurate object classification and tracking. Similarly, in industrial automation, the fusion of Radar PCBs with lidar and ultrasonic sensors can improve the navigation and obstacle avoidance capabilities of mobile robots.

Miniaturization and Low-Cost Manufacturing

As the demand for Radar PCB technology grows across various industries, there is a increasing focus on further miniaturization and low-cost manufacturing. Researchers are exploring novel materials, such as high-frequency laminates and 3D-printed substrates, to reduce the size and weight of Radar PCBs while maintaining their performance.

Moreover, advancements in manufacturing processes, such as multi-layer PCB fabrication and automated assembly techniques, are expected to drive down the production costs and make Radar PCB technology more accessible to a wider range of applications and markets.

Frequently Asked Questions (FAQ)

-

Q: What is the typical operating frequency range of Radar PCBs?

A: Radar PCBs can operate in various frequency bands, depending on the specific application and regulatory requirements. Common frequency ranges include 24 GHz, 77 GHz, and 79 GHz for automotive applications, and 5.8 GHz and 10 GHz for industrial and security applications. -

Q: Can Radar PCBs detect stationary objects?

A: Yes, Radar PCBs can detect both moving and stationary objects. By analyzing the amplitude and phase of the reflected RF signals, the system can determine the presence and distance of stationary objects in the environment. -

Q: How does the weather affect the performance of Radar PCBs?

A: Weather conditions, such as heavy rain, snow, or fog, can affect the performance of Radar PCBs by attenuating and scattering the RF signals. However, compared to other sensing technologies, such as cameras and lidar, Radar PCBs are relatively less sensitive to adverse weather conditions and can provide reliable detection results in most scenarios. -

Q: What is the typical detection range of Radar PCBs?

A: The detection range of Radar PCBs depends on various factors, such as the operating frequency, antenna design, transmit power, and target characteristics. In general, automotive Radar PCBs can detect objects up to 200-300 meters, while industrial and security Radar PCBs may have a shorter range of 50-100 meters. -

Q: Are Radar PCBs safe for human exposure?

A: Radar PCBs emit non-ionizing RF radiation, which is generally considered safe for human exposure at the power levels used in most applications. However, it is essential to comply with the relevant safety standards and regulations, such as the FCC and ETSI guidelines, to ensure that the Radar PCBs operate within the permissible exposure limits.

Conclusion

Radar PCB technology has emerged as a powerful and versatile solution for detection and automation applications across various industries. By integrating all the necessary electronic components onto a single, compact circuit board, Radar PCBs offer a cost-effective, scalable, and high-performance alternative to traditional radar systems.

As the technology continues to evolve, with advancements in signal processing, sensor fusion, and manufacturing techniques, Radar PCBs are poised to play an increasingly crucial role in shaping the future of automotive safety, industrial automation, security, and environmental monitoring.

However, to fully unleash the potential of Radar PCB technology, it is essential to address the challenges related to interference mitigation, sensor integration, and miniaturization. By fostering collaboration between academia, industry, and regulatory bodies, we can develop innovative solutions and standards that will drive the widespread adoption of Radar PCBs across various domains.

As we move towards a more connected, automated, and sustainable future, Radar PCB technology will undoubtedly be at the forefront of this transformation, enabling safer, smarter, and more efficient systems that enhance our quality of life and protect our environment.

No responses yet