Introduction to PTC thermistors

PTC (Positive Temperature Coefficient) thermistors are temperature-sensitive resistors whose resistance increases with rising temperature. This unique property makes them ideal for various applications in electronic circuits, including temperature sensing, current limiting, and circuit protection. In this article, we will explore the characteristics, working principles, and applications of PTC thermistors in detail.

What is a PTC Thermistor?

A PTC thermistor is a type of resistor whose resistance increases significantly as its temperature rises above a certain threshold. This behavior is known as the positive temperature coefficient effect. PTC thermistors are typically made from polycrystalline ceramic materials, such as barium titanate or lead titanate, which exhibit the PTC effect.

The resistance-temperature relationship of a PTC thermistor is non-linear and can be divided into three regions:

- Low temperature region: In this region, the resistance remains relatively constant with temperature changes.

- Switching region: As the temperature reaches a specific threshold (known as the Curie or switching temperature), the resistance begins to increase rapidly with further temperature increases.

- High temperature region: In this region, the resistance continues to increase with temperature, but at a slower rate compared to the switching region.

PTC Thermistor Characteristics

PTC thermistors exhibit several key characteristics that make them suitable for various applications:

- Positive Temperature Coefficient (PTC) effect: The resistance of a PTC thermistor increases with increasing temperature, which is the defining characteristic of these devices.

- Non-linear resistance-temperature relationship: The resistance change with temperature is not linear, and the most significant resistance change occurs in the switching region.

- Curie or switching temperature: This is the temperature at which the resistance begins to increase rapidly. The Curie temperature is determined by the material composition of the thermistor.

- Resistance ratio: This is the ratio of the resistance at the highest temperature to the resistance at the lowest temperature in the operating range.

- Response time: PTC thermistors have a relatively fast response time, typically in the range of a few seconds, depending on the size and thermal mass of the device.

How PTC Thermistors Work

The working principle of PTC thermistors is based on the positive temperature coefficient effect exhibited by certain ceramic materials. In these materials, the resistance increases with temperature due to the unique behavior of the charge carriers (electrons and holes) within the ceramic lattice.

At low temperatures, the charge carriers are trapped at grain boundaries, resulting in a high resistance. As the temperature increases, the charge carriers gain enough energy to overcome the potential barriers at the grain boundaries and move more freely through the material. This leads to a decrease in resistance.

However, as the temperature continues to rise and reaches the Curie or switching temperature, the ceramic material undergoes a phase transition. This phase transition causes the crystal structure to change, leading to a rapid increase in the potential barriers at the grain boundaries. As a result, the charge carriers become trapped again, causing a sharp increase in resistance.

Applications of PTC Thermistors

PTC thermistors find applications in various areas of electronic circuit design, including:

1. Temperature Sensing

PTC thermistors can be used as temperature sensors in a wide range of applications, such as:

- Environmental monitoring

- Automotive temperature sensing

- Household appliances

- Industrial process control

The non-linear resistance-temperature relationship of PTC thermistors allows for precise temperature measurement within their operating range. By measuring the resistance of the thermistor, the temperature can be determined using a calibration curve or lookup table.

2. Current Limiting and Circuit Protection

PTC thermistors are commonly used as resettable fuses or self-regulating current limiters in electronic circuits. When the current flowing through the thermistor exceeds a certain threshold, the device heats up, causing its resistance to increase rapidly. This increased resistance limits the current flow, protecting the circuit from damage due to overcurrent conditions.

Some examples of current limiting and circuit protection applications include:

- USB ports and other digital interfaces

- Power supplies and battery packs

- Motor starting circuits

- Telecommunications equipment

3. Thermal Management

PTC thermistors can be used for thermal management in electronic systems. By incorporating a PTC thermistor into a circuit, it can help maintain a stable operating temperature by regulating the current flow based on the temperature. This is particularly useful in applications such as:

- LED lighting

- Power amplifiers

- Battery charging systems

- Electronic control units (ECUs) in vehicles

4. Time Delay Circuits

PTC thermistors can be used to create time delay circuits. When power is applied to a PTC thermistor, it takes a certain amount of time for the device to heat up and reach its switching temperature. This time delay can be used to control the sequence of events in an electronic circuit. Time delay applications include:

- Soft start circuits for power supplies

- Motor starting circuits

- Relay control circuits

5. Temperature Compensation

PTC thermistors can be used for temperature compensation in electronic circuits. By incorporating a PTC thermistor into a circuit with a negative temperature coefficient (NTC) component, such as a transistor or diode, the overall temperature dependence of the circuit can be minimized. This is important in applications where temperature stability is critical, such as:

- Precision oscillators

- Voltage references

- Sensor calibration circuits

Selecting the Right PTC Thermistor

When choosing a PTC thermistor for a specific application, several factors should be considered:

- Curie or switching temperature: Select a thermistor with a switching temperature that matches the requirements of your application.

- Resistance ratio: Consider the resistance ratio needed for your application. A higher resistance ratio provides a greater change in resistance over the operating temperature range.

- Resistance tolerance: Determine the acceptable resistance tolerance for your application. PTC thermistors are available with tolerances ranging from ±10% to ±50%.

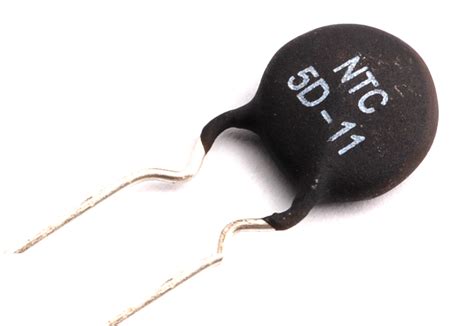

- Package type and size: Choose a package type and size that suits your circuit design and space constraints. Common package types include leaded, surface mount, and radial.

- Response time: Consider the response time required for your application. Smaller PTC thermistors generally have faster response times compared to larger ones.

- Environmental factors: Take into account the environmental conditions in which the thermistor will operate, such as temperature range, humidity, and vibration.

PTC Thermistor Selection Guide

To help select the appropriate PTC thermistor for your application, refer to the following table:

| Application | Curie Temperature (°C) | Resistance Ratio | Package Type |

|---|---|---|---|

| Temperature sensing | 50 to 150 | 100 to 10,000 | Leaded, radial |

| Current limiting | 80 to 120 | 1,000 to 10,000 | Radial, SMD |

| Circuit protection | 100 to 150 | 1,000 to 100,000 | Radial, SMD |

| Thermal management | 60 to 120 | 100 to 1,000 | Leaded, SMD |

| Time delay circuits | 60 to 100 | 100 to 1,000 | Leaded, radial |

| Temperature compensation | 50 to 100 | 100 to 1,000 | Leaded, SMD |

PTC Thermistor FAQs

1. What is the difference between a PTC thermistor and an NTC thermistor?

A PTC thermistor exhibits a positive temperature coefficient, meaning its resistance increases with increasing temperature. In contrast, an NTC (Negative Temperature Coefficient) thermistor exhibits a negative temperature coefficient, meaning its resistance decreases with increasing temperature.

2. Can PTC thermistors be used as temperature switches?

Yes, PTC thermistors can be used as temperature switches. When the temperature reaches the Curie or switching temperature, the resistance of the thermistor increases rapidly, effectively switching off the current flow in the circuit.

3. Are PTC thermistors polarized?

No, PTC thermistors are not polarized. They can be connected in either direction in a circuit without affecting their performance.

4. How do I determine the switching temperature of a PTC thermistor?

The switching temperature of a PTC thermistor is specified in the device’s datasheet. It is usually denoted as the “Curie temperature” or “switching temperature.”

5. Can PTC thermistors be used in series or parallel?

Yes, PTC thermistors can be used in series or parallel configurations, depending on the application requirements. When used in series, the total resistance is the sum of the individual thermistor resistances. When used in parallel, the total resistance is lower than the resistance of the individual thermistors.

Conclusion

PTC thermistors are versatile temperature-sensitive resistors that find applications in temperature sensing, current limiting, circuit protection, thermal management, and time delay circuits. Their unique positive temperature coefficient effect allows them to respond to changes in temperature by significantly increasing their resistance. When selecting a PTC thermistor, consider factors such as the Curie temperature, resistance ratio, package type, and environmental conditions to ensure optimal performance in your application. By understanding the characteristics and working principles of PTC thermistors, engineers and designers can effectively incorporate these devices into their electronic circuits for enhanced functionality and protection.

No responses yet