What is a PTC Thermistor?

A PTC thermistor is a type of resistor whose resistance increases significantly with a rise in temperature. This behavior is opposite to that of a standard resistor, which typically decreases in resistance as the temperature increases. The positive temperature coefficient of a PTC thermistor enables it to act as a self-regulating device, limiting current flow and protecting circuits from damage caused by excessive heat or current.

Construction and Working Principle

PTC thermistors are typically made from polycrystalline ceramic materials, such as barium titanate (BaTiO3) or lead titanate (PbTiO3), which are doped with small amounts of rare earth elements to enhance their electrical properties. The ceramic material is shaped into a disc or chip and fitted with metal electrodes on opposite sides to allow electrical connection.

The working principle of a PTC thermistor relies on the Curie temperature (Tc) of the ceramic material. Below the Curie temperature, the thermistor exhibits a relatively low and stable resistance. However, as the temperature approaches the Curie point, the resistance begins to increase rapidly, often by several orders of magnitude within a narrow temperature range. This sharp increase in resistance effectively limits the current flow through the circuit, protecting it from damage.

Applications of PTC Thermistors

PTC thermistors find applications in a wide range of industries and devices, primarily for circuit protection and temperature sensing purposes.

Circuit Protection

One of the most common applications of PTC thermistors is in circuit protection. When connected in series with a load, a PTC thermistor can limit the current flow in case of an overload or short circuit condition. As the current increases, the thermistor heats up, causing its resistance to rise and effectively reducing the current to a safe level. This self-regulating behavior helps prevent damage to sensitive electronic components and ensures the overall safety of the circuit.

PTC thermistors are widely used in the following circuit protection scenarios:

- Overcurrent protection in power supplies, battery packs, and motor circuits

- Short circuit protection in electronic devices and appliances

- Inrush current limiting in capacitive loads, such as switch-mode power supplies and LED drivers

- Overvoltage protection in telecom and datacom equipment

Temperature Sensing

PTC thermistors are also employed as temperature sensors in various applications. By monitoring the resistance change of the thermistor, it is possible to accurately measure the temperature of the surrounding environment or a specific component. The highly nonlinear resistance-temperature characteristic of PTC thermistors makes them particularly suitable for temperature sensing in applications that require a sharp switch-like response at a specific temperature threshold.

Some common temperature sensing applications of PTC thermistors include:

- Overheating protection in motors, transformers, and power electronics

- Temperature monitoring in battery packs and charging systems

- Thermal management in HVAC systems and home appliances

- Temperature control in industrial processes and medical equipment

Choosing the Right PTC Thermistor

When selecting a PTC thermistor for a specific application, several key parameters need to be considered to ensure optimal performance and reliability.

Key Parameters

-

Nominal resistance (R25): The resistance value at 25°C, which serves as a reference point for the thermistor’s temperature-resistance relationship.

-

Curie temperature (Tc): The temperature at which the thermistor’s resistance begins to increase rapidly, typically by several orders of magnitude.

-

Resistance-temperature characteristic: The relationship between the thermistor’s resistance and temperature, often represented by a graph or table.

-

Maximum operating voltage and current: The highest voltage and current levels the thermistor can withstand without damage.

-

Response time: The time required for the thermistor to react to a change in temperature or current.

-

Package type and size: The physical dimensions and mounting options of the thermistor, which should be compatible with the intended application.

Selecting the Appropriate PTC Thermistor

To choose the right PTC thermistor for a given application, follow these steps:

-

Determine the primary function of the thermistor (circuit protection or temperature sensing) and the specific requirements of the application.

-

Consider the operating temperature range and the desired trip point or Curie temperature.

-

Evaluate the maximum voltage and current levels in the circuit and ensure the thermistor can handle these values.

-

Select a thermistor with an appropriate nominal resistance and resistance-temperature characteristic that matches the application requirements.

-

Choose a package type and size that is compatible with the circuit layout and available space.

-

Verify the thermistor’s response time is suitable for the application, particularly in time-critical scenarios.

By carefully considering these factors and consulting manufacturer datasheets and application notes, designers can select the optimal PTC thermistor for their specific needs.

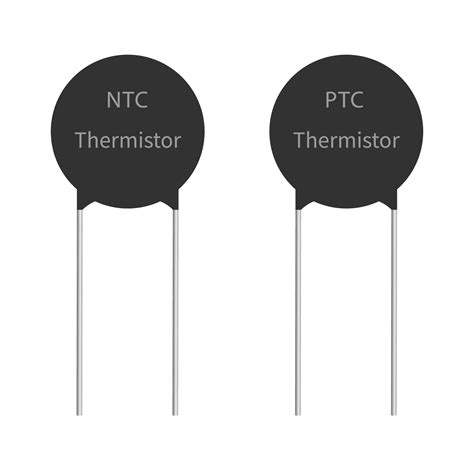

PTC Thermistor vs. NTC Thermistor

While PTC thermistors are widely used for circuit protection and temperature sensing, another type of thermistor, the NTC (Negative Temperature Coefficient) thermistor, is also commonly employed in temperature sensing applications. It is essential to understand the differences between these two types of thermistors to select the most suitable component for a given application.

NTC Thermistor Characteristics

NTC thermistors exhibit a decrease in resistance as the temperature increases, which is the opposite behavior of PTC thermistors. The resistance-temperature relationship of NTC thermistors is highly nonlinear and can be approximated by the Steinhart-Hart equation. NTC thermistors are often used for precise temperature measurement and control in applications such as:

- Temperature compensation in electronic circuits

- Environmental temperature monitoring

- Medical and laboratory equipment

- Automotive temperature sensing

Comparison of PTC and NTC Thermistors

The table below summarizes the key differences between PTC and NTC thermistors:

| Parameter | PTC Thermistor | NTC Thermistor |

|---|---|---|

| Resistance-temperature relationship | Positive (resistance increases with temperature) | Negative (resistance decreases with temperature) |

| Primary applications | Circuit protection, temperature sensing (switch-like response) | Precise temperature measurement and control |

| Resistance change | Highly nonlinear, sharp increase near Curie temperature | Highly nonlinear, gradual decrease with increasing temperature |

| Typical resistance range | 10 Ω to 1 kΩ | 100 Ω to 1 MΩ |

| Temperature range | -40°C to 150°C | -50°C to 150°C |

| Response time | Fast (milliseconds) | Slower (seconds) |

When choosing between a PTC and NTC thermistor, consider the specific requirements of the application, such as the desired temperature range, sensitivity, and response time. PTC thermistors are generally better suited for circuit protection and applications requiring a sharp switch-like response, while NTC thermistors are preferred for precise temperature measurement and control.

Frequently Asked Questions (FAQ)

1. What is the main difference between a PTC thermistor and a standard resistor?

A PTC thermistor exhibits a positive temperature coefficient, meaning its resistance increases significantly with a rise in temperature. In contrast, a standard resistor typically has a small negative temperature coefficient, causing its resistance to decrease slightly as the temperature increases.

2. How does a PTC thermistor protect a circuit from overcurrent?

When connected in series with a load, a PTC thermistor can limit the current flow in case of an overload or short circuit condition. As the current increases, the thermistor heats up, causing its resistance to rise and effectively reducing the current to a safe level. This self-regulating behavior helps prevent damage to sensitive electronic components.

3. Can a PTC thermistor be used for precise temperature measurement?

While PTC thermistors can be used for temperature sensing, their highly nonlinear resistance-temperature characteristic makes them more suitable for applications requiring a sharp switch-like response at a specific temperature threshold. For precise temperature measurement, NTC thermistors are generally preferred due to their more gradual and predictable resistance change with temperature.

4. What is the Curie temperature of a PTC thermistor?

The Curie temperature (Tc) is the temperature at which a PTC thermistor’s resistance begins to increase rapidly, typically by several orders of magnitude within a narrow temperature range. This sharp increase in resistance effectively limits the current flow through the circuit, protecting it from damage.

5. How do I select the appropriate PTC thermistor for my application?

To select the right PTC thermistor, consider the following factors:

- Primary function (circuit protection or temperature sensing)

- Operating temperature range and desired trip point or Curie temperature

- Maximum voltage and current levels in the circuit

- Nominal resistance and resistance-temperature characteristic

- Package type and size compatibility with the circuit layout

- Required response time for the application

Consult manufacturer datasheets and application notes to find the optimal PTC thermistor that meets your specific requirements.

Conclusion

PTC thermistors are versatile temperature-sensitive resistors that play a crucial role in electronic circuit protection and temperature sensing applications. By exhibiting a sharp increase in resistance near their Curie temperature, PTC thermistors effectively limit current flow and protect sensitive components from damage caused by overcurrent or overheating.

When selecting a PTC thermistor, designers must consider various factors, such as the application requirements, operating temperature range, maximum voltage and current levels, and package compatibility. By carefully evaluating these parameters and consulting manufacturer resources, engineers can choose the optimal PTC thermistor for their specific needs, ensuring reliable and efficient operation of their electronic systems.

As technology continues to advance, PTC thermistors will likely find new applications in emerging fields, such as renewable energy, electric vehicles, and the Internet of Things (IoT). By understanding the principles and characteristics of these essential components, designers can create more robust, safe, and innovative electronic solutions for a wide range of industries.

No responses yet