What is PLM-EM?

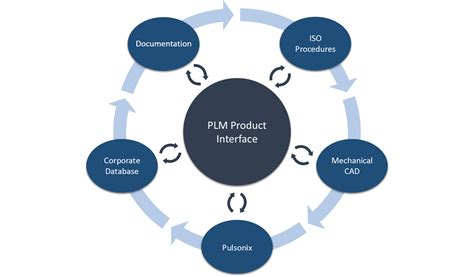

Product Lifecycle Management for Electronics Manufacturing (PLM-EM) is the application of PLM principles and software tools to manage the entire lifecycle of electronic products, from initial concept through design, manufacturing, service, and end-of-life. PLM-EM integrates people, data, processes and business systems to provide a product information backbone for electronics companies and their extended enterprise.

The goal of PLM-EM is to improve product quality, reduce costs, and accelerate time-to-market by providing a centralized repository for all product-related information and streamlining communication and collaboration across the entire product lifecycle. By managing the complete digital product definition, PLM-EM enables electronics manufacturers to optimize designs for manufacturability, collaborate more effectively with suppliers, and respond quickly to changing market demands and regulatory requirements.

Key Benefits of PLM-EM

Implementing PLM-EM can provide significant benefits for electronics manufacturers, including:

-

Faster time-to-market: PLM-EM streamlines the product development process, enabling companies to bring new products to market faster and more efficiently.

-

Improved product quality: By providing a single source of truth for product information and enabling collaboration across the product lifecycle, PLM-EM helps ensure that products are designed and manufactured to the highest quality standards.

-

Reduced costs: PLM-EM can help reduce costs by optimizing designs for manufacturability, minimizing errors and rework, and improving supply chain collaboration.

-

Enhanced collaboration: PLM-EM provides a centralized platform for collaboration, enabling teams across the enterprise to work together more effectively and efficiently.

-

Improved compliance: PLM-EM helps electronics manufacturers meet regulatory requirements and industry standards by providing full traceability and documentation of the product lifecycle.

PLM-EM Functionality

PLM-EM systems typically include the following key functionality:

Product Data Management (PDM)

PDM is the foundation of PLM-EM, providing a centralized repository for all product-related data, including CAD files, BOMs, specifications, and documentation. PDM enables version control, access control, and change management to ensure that everyone is working with the latest and most accurate product information.

Bill of Materials (BOM) Management

PLM-EM includes tools for managing the complete product BOM, from design through manufacturing and service. This includes managing different types of BOMs (eBOM, mBOM, sBOM), as well as enabling collaboration and change management across the BOM lifecycle.

Change Management

PLM-EM provides robust change management capabilities, enabling electronics manufacturers to manage engineering changes, ECOs, and product revisions throughout the product lifecycle. This includes workflow automation, impact analysis, and full traceability of changes.

Compliance Management

PLM-EM helps electronics manufacturers manage compliance with regulatory requirements and industry standards, such as RoHS, REACH, and conflict minerals reporting. This includes tracking and reporting on material composition, generating compliance documentation, and managing supplier compliance.

Manufacturing Process Management (MPM)

PLM-EM includes tools for managing the manufacturing process, from initial planning through production and quality control. This includes managing work instructions, process plans, and quality data, as well as enabling collaboration with suppliers and contract manufacturers.

Supply Chain Collaboration

PLM-EM enables collaboration with suppliers and partners across the extended enterprise, providing a platform for sharing product data, managing supplier quality and compliance, and optimizing the supply chain.

PLM-EM Implementation Considerations

Implementing PLM-EM can be a complex undertaking, requiring significant planning, resources, and change management. Key considerations for a successful PLM-EM implementation include:

-

Defining business objectives and requirements: It’s important to clearly define the business objectives and requirements for PLM-EM, including the specific processes and data that will be managed in the system.

-

Selecting the right PLM-EM software: There are many PLM-EM software options available, each with different features and capabilities. It’s important to carefully evaluate and select the software that best meets the company’s requirements and integrates with existing systems.

-

Data migration and integration: Migrating existing product data into the PLM-EM system and integrating with other enterprise systems (e.g. ERP, MES, CRM) can be a significant challenge. It’s important to develop a comprehensive data migration and integration strategy to ensure data accuracy and consistency.

-

Process standardization and optimization: Implementing PLM-EM provides an opportunity to standardize and optimize product development and manufacturing processes. This may require significant process re-engineering and change management.

-

User adoption and training: The success of a PLM-EM implementation depends on user adoption and effective use of the system. It’s important to provide comprehensive training and support to ensure that users are able to effectively use the system to achieve business objectives.

PLM-EM Best Practices

To maximize the benefits of PLM-EM, electronics manufacturers should follow these best practices:

-

Start with a clear vision and strategy: Develop a clear vision and strategy for PLM-EM that aligns with business objectives and defines the specific processes and data that will be managed in the system.

-

Focus on data quality and governance: Ensure that product data is accurate, consistent, and complete across the enterprise by implementing robust data governance processes and tools.

-

Standardize and optimize processes: Use PLM-EM as an opportunity to standardize and optimize product development and manufacturing processes, leveraging best practices and industry standards.

-

Enable collaboration and communication: Foster collaboration and communication across the enterprise and with suppliers and partners by providing a centralized platform for sharing product data and managing processes.

-

Continuously measure and improve: Establish metrics and KPIs to measure the effectiveness of PLM-EM and continuously identify opportunities for improvement.

PLM-EM Success Stories

Many electronics manufacturers have successfully implemented PLM-EM and achieved significant benefits. Here are a few examples:

Cisco Systems

Cisco Systems, a leading provider of networking equipment and solutions, implemented PLM-EM to manage the complex product lifecycle of its products, from concept through end-of-life. By consolidating product data and processes in a single system, Cisco was able to reduce time-to-market by 25%, improve product quality, and reduce costs.

Philips Healthcare

Philips Healthcare, a global leader in healthcare technology, implemented PLM-EM to manage the development and manufacturing of its medical devices. By streamlining processes and enabling collaboration across the enterprise, Philips was able to reduce product development cycle times by 30%, improve compliance with regulatory requirements, and enhance product quality and reliability.

Siemens Digital Industries Software

Siemens Digital Industries Software, a leading provider of PLM software and services, has helped many electronics manufacturers implement PLM-EM to achieve significant benefits. For example, one customer, a leading provider of automotive electronics, was able to reduce engineering change cycle times by 50%, improve product quality, and reduce warranty costs by implementing Siemens’ PLM-EM solution.

The Future of PLM-EM

As the electronics industry continues to evolve and become more complex, the importance of PLM-EM will only continue to grow. Here are a few key trends and developments that are shaping the future of PLM-EM:

-

Digital Twin: The concept of a digital twin, a virtual representation of a physical product or system, is becoming increasingly important in PLM-EM. By creating a digital twin of a product, manufacturers can simulate and optimize product performance, predict maintenance needs, and improve overall product quality and reliability.

-

Internet of Things (IoT): The proliferation of connected devices and the IoT is creating new opportunities and challenges for PLM-EM. Manufacturers need to be able to manage the complete lifecycle of connected products, from initial design through ongoing service and support.

-

Artificial Intelligence (AI) and Machine Learning (ML): AI and ML are being increasingly applied in PLM-EM to automate and optimize processes, improve decision-making, and enable predictive analytics. For example, AI can be used to analyze product data to identify potential quality issues or optimize product designs for manufacturability.

-

Cloud-based PLM-EM: Many PLM-EM software providers are moving to cloud-based delivery models, enabling manufacturers to access PLM-EM capabilities on-demand and at scale. Cloud-based PLM-EM can reduce IT costs and complexity, enable faster implementation and updates, and provide greater flexibility and scalability.

Frequently Asked Questions (FAQ)

- What is the difference between PLM and PDM?

-

PDM (Product Data Management) is a subset of PLM that focuses specifically on managing product data, such as CAD files, BOMs, and documentation. PLM is a broader concept that encompasses PDM as well as other processes and capabilities related to managing the complete product lifecycle.

-

How long does it typically take to implement PLM-EM?

-

The timeline for implementing PLM-EM can vary widely depending on the size and complexity of the organization, the scope of the implementation, and the specific software and processes being implemented. A typical PLM-EM implementation can take anywhere from several months to a year or more.

-

What are the key challenges in implementing PLM-EM?

-

Some of the key challenges in implementing PLM-EM include data migration and integration, process standardization and optimization, user adoption and training, and change management. Overcoming these challenges requires careful planning, executive sponsorship, and a focus on continuous improvement.

-

How much does PLM-EM software cost?

-

The cost of PLM-EM software can vary widely depending on the specific software provider, the size of the organization, and the scope of the implementation. Costs can range from tens of thousands to millions of dollars, depending on these factors. Many PLM-EM software providers offer different licensing and pricing models, such as perpetual licenses, subscription-based pricing, or pay-per-use models.

-

What are the key criteria for selecting PLM-EM software?

- When selecting PLM-EM software, key criteria to consider include functionality and capabilities, ease of use and user experience, integration with existing systems and processes, scalability and performance, vendor support and expertise, and total cost of ownership. It’s important to carefully evaluate and compare different PLM-EM software options to find the best fit for the organization’s specific needs and requirements.

Conclusion

Product Lifecycle Management for Electronics Manufacturing (PLM-EM) is a critical capability for electronics companies looking to improve product quality, reduce costs, and accelerate time-to-market. By providing a centralized platform for managing product data and processes across the complete product lifecycle, PLM-EM enables collaboration, innovation, and continuous improvement.

While implementing PLM-EM can be a complex and challenging undertaking, the benefits are significant and well-documented. By following best practices and leveraging the latest technologies and trends, such as digital twin, IoT, AI and ML, and cloud-based PLM-EM, electronics manufacturers can achieve a competitive advantage and drive long-term success.

As the electronics industry continues to evolve and become more complex, the importance of PLM-EM will only continue to grow. Companies that invest in PLM-EM and make it a strategic priority will be well-positioned to meet the challenges and opportunities of the future.

No responses yet