Introduction to Printed Electronics

Printed electronics is a groundbreaking technology that has revolutionized the way we manufacture and use electronic devices. This innovative approach involves the use of printing techniques to create electronic circuits and components on various substrates, such as paper, plastic, or fabric. The technology has gained significant attention in recent years due to its potential to enable the mass production of low-cost, flexible, and lightweight electronic devices.

What is Printed Electronics?

Printed electronics refers to the process of creating electronic devices and circuits using printing methods, such as screen printing, inkjet printing, and gravure printing. These methods involve the deposition of conductive, semiconductive, or dielectric materials in the form of inks or pastes onto a substrate to create functional electronic components.

Advantages of Printed Electronics

Compared to traditional electronic manufacturing methods, printed electronics offers several advantages:

- Cost-effectiveness: Printed electronics enables the production of electronic devices at a lower cost due to the use of inexpensive materials and high-throughput printing processes.

- Flexibility: The use of flexible substrates allows for the creation of bendable, stretchable, and conformable electronic devices, opening up new possibilities for applications in wearable technology, smart packaging, and more.

- Scalability: Printing techniques enable the mass production of electronic devices, making it possible to manufacture large quantities of products quickly and efficiently.

- Environmental friendliness: Printed electronics often uses eco-friendly materials and processes, reducing the environmental impact of electronic manufacturing.

History and Evolution of Printed Electronics

The concept of printed electronics can be traced back to the early 20th century when the first printed circuit boards (PCBs) were developed. However, it wasn’t until the 1990s that the field of printed electronics began to gain momentum with the advent of new printing technologies and materials.

Early Developments

- 1903: Albert Hanson, a German scientist, patents the first printed circuit.

- 1936: Paul Eisler, an Austrian inventor, creates the first operational printed circuit board.

- 1947: The first commercial printed circuit board is produced in the United States.

Advancements in Printing Technologies

- 1950s: Screen printing becomes a popular method for creating printed circuits.

- 1970s: The development of photolithography enables the creation of high-resolution printed circuits.

- 1980s: Inkjet printing technology emerges, allowing for the precise deposition of conductive inks.

- 1990s: The advent of organic semiconductors and conductive polymers opens up new possibilities for printed electronics.

Milestone Applications

| Year | Application |

|---|---|

| 2002 | First fully printed organic transistor |

| 2007 | First printed OLED display |

| 2010 | First printed solar cell with 8% efficiency |

| 2012 | First printed graphene-based supercapacitor |

| 2015 | First fully printed wearable electronic device |

Current Applications of Printed Electronics

Printed electronics has found its way into various industries and applications, offering innovative solutions and enabling new products and services.

Smart Packaging

Printed electronics has revolutionized the packaging industry by enabling the integration of electronic functionality into packaging materials. Some examples include:

- Smart labels with embedded sensors for monitoring product freshness, temperature, or humidity

- Interactive packaging with built-in displays or LED lights

- Anti-counterfeiting measures using printed RFID tags

Wearable Technology

The flexibility and lightweight nature of printed electronics make it ideal for creating wearable devices:

- Printed sensors for monitoring vital signs, such as heart rate or blood pressure

- Flexible displays integrated into clothing or accessories

- Printed antennas for wireless communication

Medical Devices

Printed electronics has the potential to revolutionize the healthcare industry by enabling the development of low-cost, disposable medical devices:

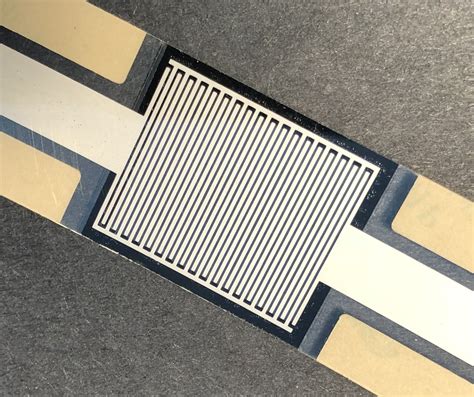

- Printed biosensors for detecting specific biomarkers or pathogens

- Flexible electrodes for monitoring brain activity or muscle stimulation

- Printed drug delivery patches with controlled release mechanisms

Energy Harvesting and Storage

Printed electronics can be used to create energy harvesting and storage devices:

- Printed solar cells for converting light into electricity

- Printed batteries and supercapacitors for energy storage

- Energy harvesting devices that convert motion, heat, or RF energy into electricity

Future Trends and Challenges

As printed electronics continues to evolve, several trends and challenges are shaping the future of this technology.

Emerging Materials

Researchers are continuously exploring new materials to enhance the performance and functionality of printed electronics:

- Nanomaterials, such as graphene and carbon nanotubes, for improved conductivity and mechanical properties

- Quantum dots for light-emitting and sensing applications

- Biodegradable and biocompatible materials for eco-friendly and implantable devices

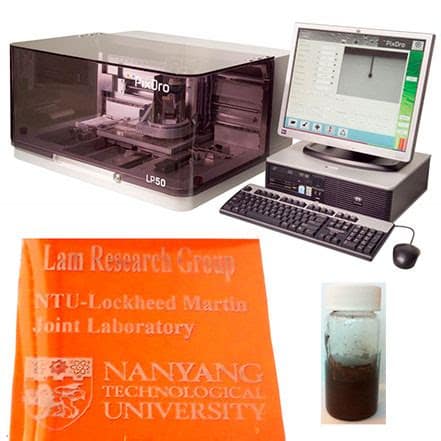

Advanced Printing Techniques

The development of new printing techniques is crucial for improving the resolution, speed, and reliability of printed electronics:

- Aerosol jet printing for high-resolution patterning

- Roll-to-roll printing for high-throughput production

- 3D printing for creating complex, multi-layer structures

Integration with Other Technologies

The convergence of printed electronics with other emerging technologies opens up new possibilities:

- Internet of Things (IoT): Printed sensors and antennas for connected devices

- Artificial Intelligence (AI): Printed neural networks and neuromorphic computing

- Biotechnology: Printed bio-electronics for interfacing with living systems

Challenges and Limitations

Despite the numerous advantages of printed electronics, there are still challenges and limitations to overcome:

- Improving the performance and stability of printed electronic devices

- Scaling up production while maintaining quality and reliability

- Addressing the variability and reproducibility of printed materials and processes

- Developing industry standards and regulations for printed electronics

Frequently Asked Questions (FAQ)

-

Q: What is the difference between printed electronics and traditional electronics?

A: Printed electronics uses printing methods to create electronic devices on various substrates, while traditional electronics relies on photolithography and etching processes to create circuits on rigid substrates like silicon wafers. -

Q: Can printed electronics replace traditional electronics completely?

A: While printed electronics offers numerous advantages, it is not likely to replace traditional electronics completely. Instead, it will complement conventional electronics by enabling new applications and products that were not possible before. -

Q: What are the most common printing techniques used in printed electronics?

A: The most common printing techniques used in printed electronics include screen printing, inkjet printing, gravure printing, and flexographic printing. -

Q: What are some of the key challenges in the commercialization of printed electronics?

A: Some of the key challenges include improving the performance and stability of printed devices, scaling up production while maintaining quality, addressing variability and reproducibility issues, and developing industry standards and regulations. -

Q: What are the potential applications of printed electronics in the future?

A: Potential future applications of printed electronics include smart packaging, wearable technology, medical devices, energy harvesting and storage, Internet of Things (IoT), artificial intelligence, and bio-electronics.

Conclusion

Printed electronics has come a long way since its early beginnings, and it continues to evolve at a rapid pace. With its unique advantages, such as cost-effectiveness, flexibility, and scalability, printed electronics has the potential to revolutionize various industries and enable new applications that were not possible before.

As researchers and industries continue to explore new materials, printing techniques, and applications, the future of printed electronics looks bright. However, there are still challenges and limitations to overcome, such as improving device performance, scaling up production, and addressing variability and reproducibility issues.

Despite these challenges, the potential benefits of printed electronics are too significant to ignore. As the technology continues to advance, we can expect to see more innovative products and solutions that leverage the power of printed electronics to create a smarter, more connected, and sustainable future.

No responses yet