Introduction to the CST-PDN-Analyzer

The CST-PDN-Analyzer is a cutting-edge tool developed by the simulation experts at CST for analyzing power distribution networks (PDNs). It offers powerful features and capabilities to help engineers design reliable and efficient PDNs for modern electronic systems.

Some key benefits of the CST-PDN-Analyzer include:

- Advanced simulation and modeling of PDNs

- Identification of potential issues like voltage drop and excessive noise

- Optimization of PDN designs for improved performance

- Integration with other CST tools for a complete design workflow

By leveraging the CST-PDN-Analyzer, companies can accelerate development cycles, reduce costs, and ensure their products meet strict power integrity requirements. Let’s take a closer look at how this innovative solution works.

How the CST-PDN-Analyzer Works

At its core, the CST-PDN-Analyzer uses sophisticated algorithms and numerical methods to simulate the behavior of PDNs under various operating conditions. It takes into account factors such as:

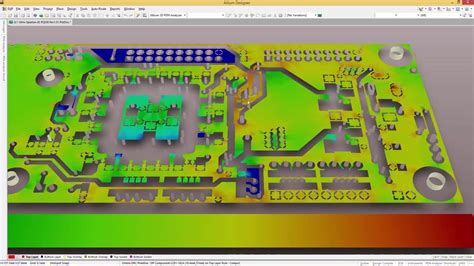

- Component layouts and interconnects

- Material properties

- Power supply characteristics

- Load profiles

The tool constructs detailed models of the PDN, which are then solved using techniques like the finite element method (FEM) and boundary element method (BEM). This allows engineers to gain deep insights into PDN performance prior to physical prototyping.

Some specific capabilities of the CST-PDN-Analyzer include:

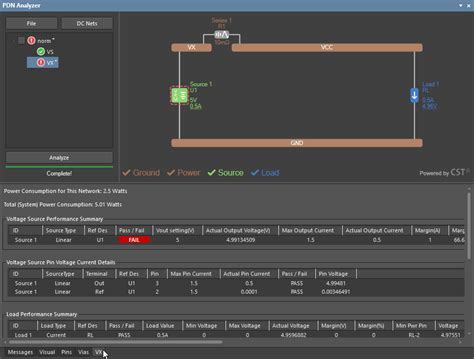

1. DC Drop Analysis

One of the primary functions of the tool is to analyze DC voltage drops across the PDN. Excessive voltage drops can cause components to operate outside their specified ranges, leading to reliability issues.

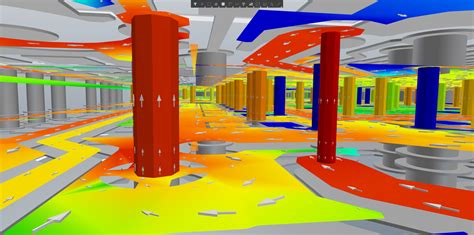

The CST-PDN-Analyzer calculates voltages at every node in the network and identifies areas where drops exceed acceptable thresholds. It provides intuitive visualizations like color-coded plots to highlight problem areas.

Example DC drop analysis results:

| Component | Nominal Voltage (V) | Actual Voltage (V) | Voltage Drop (%) |

|---|---|---|---|

| IC1 | 1.2 | 1.08 | 10% |

| IC2 | 1.2 | 1.15 | 4.2% |

| IC3 | 1.2 | 1.05 | 12.5% |

In this example, the voltage drop for IC3 exceeds 10%, indicating a potential issue that requires further investigation and mitigation.

2. AC Impedance Analysis

In addition to DC drops, the CST-PDN-Analyzer also evaluates the AC impedance characteristics of PDNs. Impedance variations over frequency can cause signal integrity problems like ringing, reflections, and electromagnetic interference (EMI).

The tool sweeps through a range of frequencies and calculates impedances at each point. It generates impedance curves and identifies resonant peaks that could lead to unwanted behaviors.

Example AC impedance plot:

Impedance (Ohms)

|

10 | *

| * *

| * *

1 | * *

| * *

| * * *

0.1 | * *

| * *

+--------------------------

1M 10M 100M 1G 10G

Frequency (Hz)

In this example, there are resonant peaks at around 50 MHz and 2 GHz, which could cause issues if left unaddressed. The CST-PDN-Analyzer helps engineers identify and mitigate these resonances through techniques like decoupling capacitor placement and power plane optimizations.

3. Transient Analysis

The CST-PDN-Analyzer also offers transient analysis capabilities to study the time-domain response of PDNs. This is important for evaluating metrics like power supply noise, load step response, and dynamic voltage variations.

The tool simulates the PDN under different transient loading scenarios and generates waveforms showing voltages and currents over time. It helps engineers ensure that voltage fluctuations remain within acceptable bounds and that the PDN can handle sudden load changes.

Example transient waveform:

Voltage (V)

1.3 |

|

1.2 | ------ ------

| ----

1.1 |

|

1.0 |

+---------------------------

0 100 200 300 400

Time (ns)

In this example, the voltage dips by around 100 mV when the load current increases, but recovers within a few nanoseconds. The CST-PDN-Analyzer allows engineers to fine-tune parameters like decoupling capacitor values and placement to optimize transient response.

Advanced Features of the CST-PDN-Analyzer

Beyond the core simulation capabilities, the CST-PDN-Analyzer offers several advanced features to streamline the design process and provide additional insights. Some highlights include:

1. Parametric Sweeps

The tool supports parametric sweeps, allowing engineers to explore the impact of design changes quickly. For example, you can sweep the values of decoupling capacitors or the spacing between power and ground planes to find the optimal configuration.

Example parametric sweep results:

| Capacitor Value (nF) | Impedance at 100 MHz (mOhms) |

|---|---|

| 1 | 250 |

| 10 | 95 |

| 22 | 57 |

| 47 | 36 |

By sweeping the decoupling capacitor value, the engineer can identify the point of diminishing returns and select an appropriate value that balances performance and cost.

2. Design Rule Checking (DRC)

The CST-PDN-Analyzer includes built-in design rule checks to catch common PDN layout errors. It can flag issues like insufficient via spacing, inadequate copper coverage, and improper plane assignments.

By running DRC early in the design process, engineers can avoid costly mistakes and ensure their layouts are manufacturable and compliant with industry standards.

3. Integration with Other Tools

The tool integrates seamlessly with other CST solutions, allowing for a cohesive design flow. For example, you can import layouts from CST PCB Studio, simulate them in the CST-PDN-Analyzer, and then optimize them using CST BOARDCHECK.

This integration reduces the risk of errors from manual data transfer and speeds up the overall design process. It also enables engineers to leverage the full suite of CST tools for a comprehensive analysis of their designs.

Case Studies and Success Stories

Many leading companies across industries have adopted the CST-PDN-Analyzer to improve their PDN designs and streamline their product development processes. Here are a few success stories:

1. Smartphone Manufacturer

A major smartphone manufacturer used the CST-PDN-Analyzer to optimize the PDN for their latest flagship device. By simulating the PDN early in the design cycle, they were able to:

- Reduce the number of board spins from 4 to 2

- Improve battery life by 10% through more efficient power delivery

- Eliminate EMI issues that had plagued previous designs

2. Automotive Tier 1 Supplier

An automotive tier 1 supplier leveraged the CST-PDN-Analyzer to design the PDN for a new electronic control unit (ECU). The tool helped them:

- Ensure reliable operation across a wide temperature range (-40°C to +125°C)

- Meet stringent EMC requirements for automotive applications

- Reduce the ECU footprint by 20% through optimized component placement and routing

3. Data Center Operator

A leading data center operator used the CST-PDN-Analyzer to design the PDN for their next-generation server motherboards. The tool allowed them to:

- Handle the high power demands of modern CPUs and GPUs

- Minimize voltage variations under dynamic loading conditions

- Achieve a 99.999% uptime target through robust power delivery

These success stories demonstrate the versatility and effectiveness of the CST-PDN-Analyzer across different applications and industries. By adopting this powerful tool, companies can gain a competitive edge and deliver products that meet the most demanding performance and reliability requirements.

Frequently Asked Questions (FAQ)

1. What types of designs can the CST-PDN-Analyzer simulate?

The CST-PDN-Analyzer can simulate PDNs for a wide range of electronic systems, including:

- Printed circuit boards (PCBs)

- Integrated circuits (ICs)

- Multi-chip modules (MCMs)

- System-in-package (SiP) devices

It supports various technologies and materials, such as rigid and flexible substrates, high-speed interconnects, and advanced packaging solutions.

2. How does the CST-PDN-Analyzer compare to other PDN analysis tools?

The CST-PDN-Analyzer offers several advantages over other tools on the market, such as:

- Comprehensive simulation capabilities covering DC, AC, and transient analyses

- Seamless integration with other CST tools for a complete design flow

- Advanced features like parametric sweeps and design rule checking

- Intuitive user interface and visualization options

It also benefits from the expertise and support of the CST team, who have decades of experience in electromagnetic simulation and analysis.

3. What are the system requirements for running the CST-PDN-Analyzer?

The CST-PDN-Analyzer runs on Windows, Linux, and macOS platforms. The recommended system requirements are:

- Processor: Intel Core i7 or equivalent

- RAM: 16 GB or more

- Storage: 500 GB or more

- Graphics: Dedicated GPU with 2 GB or more memory

For large and complex designs, additional computing resources like high-performance computing (HPC) clusters may be necessary.

4. How long does it take to learn and use the CST-PDN-Analyzer effectively?

The learning curve for the CST-PDN-Analyzer depends on the user’s background and experience with similar tools. However, CST provides comprehensive documentation, tutorials, and training resources to help users get up to speed quickly.

Most engineers can become proficient with the tool within a few weeks of regular use. CST also offers professional services and support to assist customers with their specific needs and challenges.

5. How can I get started with the CST-PDN-Analyzer?

To get started with the CST-PDN-Analyzer, you can:

- Request a demo or evaluation license from CST

- Attend a training course or webinar hosted by CST experts

- Explore the documentation and tutorials provided with the tool

- Engage with the CST support team for guidance and assistance

CST is committed to helping customers succeed with their tools and provides a range of resources and services to support them throughout the design process.

Conclusion

The CST-PDN-Analyzer is a powerful and versatile tool for analyzing and optimizing PDNs in modern electronic systems. With its advanced simulation capabilities, intuitive interface, and seamless integration with other CST tools, it helps engineers design reliable and efficient power delivery networks faster than ever before.

By adopting the CST-PDN-Analyzer, companies can:

- Reduce design cycles and time-to-market

- Improve product performance and reliability

- Lower development and manufacturing costs

- Gain a competitive edge in their industries

As electronic systems continue to push the boundaries of performance and complexity, tools like the CST-PDN-Analyzer will become increasingly essential for success. With its proven track record and continuous innovation, CST is well-positioned to support engineers in meeting the power integrity challenges of today and tomorrow.

No responses yet