Introduction to Potentiometers

A potentiometer, often referred to as a “pot,” is a three-terminal variable resistor commonly used in electronic circuits to control voltage, current, or other parameters. It consists of a resistive element with a sliding contact (wiper) that moves along the element, allowing the user to adjust the resistance between the wiper and the two fixed ends of the potentiometer.

Potentiometers are essential components in various applications, such as:

– Volume control in audio devices

– Brightness control in displays and lighting systems

– Speed control in motors

– Position sensing in robotics and automation

Types of Potentiometers

There are several types of potentiometers available, each with its own characteristics and suitable applications:

-

Linear Potentiometers: These potentiometers have a uniform resistive element, resulting in a linear relationship between the wiper position and the resistance. They are commonly used for volume control, faders, and other applications requiring a linear response.

-

Logarithmic Potentiometers: Also known as audio taper potentiometers, these have a non-linear resistive element that provides a logarithmic relationship between the wiper position and the resistance. They are often used in audio applications, such as volume control, to compensate for the human ear’s logarithmic perception of sound.

-

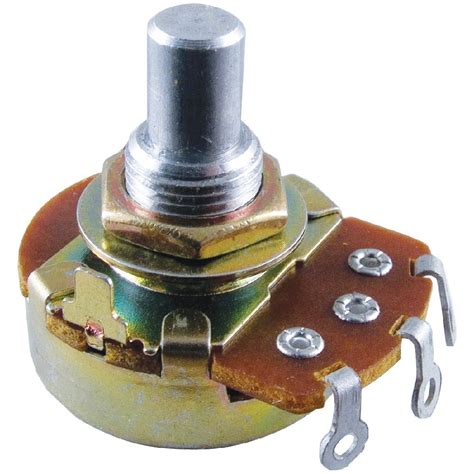

Rotary Potentiometers: These potentiometers have a circular resistive element and a rotating shaft that moves the wiper. They are available in both linear and logarithmic variants and are commonly used for knobs and dials in various electronic devices.

-

Slide Potentiometers: Also called slider potentiometers, these have a linear resistive element and a sliding wiper that moves along a straight path. They are often used for faders, equalizers, and other applications requiring a linear sliding motion.

-

Trimmer Potentiometers: These are small, adjustable potentiometers designed for fine-tuning and calibration purposes. They are typically mounted on circuit boards and adjusted using a screwdriver or a similar tool. Trimmers are available in various sizes and styles, such as single-turn and multi-turn variants.

Understanding Potentiometer Terminals

Potentiometers have three terminals, each serving a specific purpose in the circuit:

-

Terminal 1: This is one of the fixed ends of the resistive element, often labeled as “1,” “A,” or “-“.

-

Terminal 2: This is the wiper terminal, which is connected to the sliding contact that moves along the resistive element. It is typically labeled as “2,” “W,” or “S” (for slider).

-

Terminal 3: This is the other fixed end of the resistive element, usually labeled as “3,” “B,” or “+”.

Potentiometer Schematic Symbol

The schematic symbol for a potentiometer is shown below:

┌───────────┐

──┤1 3├──

│ │

└──────┬───┘

│

└─ 2

In this symbol, terminals 1 and 3 represent the fixed ends of the resistive element, while terminal 2 represents the wiper.

Wiring a Potentiometer

Wiring a potentiometer is a straightforward process, but it’s essential to understand the function of each terminal and the desired configuration for your specific application.

Basic Wiring Configuration

The most common wiring configuration for a potentiometer is as follows:

- Connect terminal 1 to the ground or the negative side of the power supply.

- Connect terminal 3 to the positive side of the power supply or the reference voltage.

- Connect terminal 2 (the wiper) to the input of the circuit or device being controlled.

In this configuration, the voltage at the wiper (terminal 2) will vary between the voltages at terminals 1 and 3 as the potentiometer is adjusted.

Voltage Divider Configuration

Potentiometers are often used in a voltage divider configuration, where the output voltage is a fraction of the input voltage determined by the position of the wiper. To create a voltage divider:

- Connect terminal 1 to the ground or the negative side of the power supply.

- Connect terminal 3 to the input voltage.

- Connect terminal 2 (the wiper) to the output of the voltage divider.

The output voltage (V_out) can be calculated using the following formula:

V_out = V_in × (R_2 / (R_1 + R_2))

Where:

– V_in is the input voltage

– R_1 is the resistance between terminals 1 and 2

– R_2 is the resistance between terminals 2 and 3

Variable Resistor Configuration

In some cases, you may want to use a potentiometer as a variable resistor. To achieve this:

- Use only two of the potentiometer’s terminals, either terminals 1 and 2 or terminals 2 and 3.

- Connect these terminals in series with the circuit element you want to control.

In this configuration, the potentiometer acts as a variable resistor, with its resistance determined by the position of the wiper.

Potentiometer Wiring Examples

Now that we’ve covered the basics of potentiometer wiring, let’s look at some practical examples of how to wire potentiometers in various applications.

Example 1: Audio Volume Control

In this example, we’ll use a logarithmic potentiometer to control the volume of an audio signal:

- Connect terminal 1 of the potentiometer to the ground.

- Connect terminal 3 to the audio input signal.

- Connect terminal 2 (the wiper) to the input of the audio amplifier.

As the potentiometer is adjusted, the audio signal level sent to the amplifier will change, effectively controlling the volume.

Example 2: LED Brightness Control

To control the brightness of an LED using a linear potentiometer:

- Connect terminal 1 of the potentiometer to the ground.

- Connect terminal 3 to the positive side of the power supply.

- Connect terminal 2 (the wiper) to the anode (positive side) of the LED.

- Connect a Current-Limiting Resistor between the cathode (negative side) of the LED and the ground.

Adjusting the potentiometer will change the voltage supplied to the LED, thus controlling its brightness.

Example 3: Motor Speed Control

To control the speed of a DC motor using a potentiometer:

- Connect terminal 1 of the potentiometer to the ground.

- Connect terminal 3 to the positive side of the power supply.

- Connect terminal 2 (the wiper) to the input of a motor driver or a PWM (Pulse Width Modulation) controller.

- Connect the output of the motor driver or PWM controller to the motor.

As the potentiometer is adjusted, the voltage or PWM signal sent to the motor driver will change, consequently controlling the motor’s speed.

Potentiometer Wiring Tips and Best Practices

To ensure reliable and efficient potentiometer wiring, consider the following tips and best practices:

-

Choose the right type of potentiometer: Select a potentiometer with the appropriate taper (linear or logarithmic) and resistance range for your application.

-

Use proper wiring techniques: Ensure that all connections are secure and properly insulated to prevent short circuits and other wiring issues.

-

Consider potentiometer power rating: Make sure that the potentiometer can handle the current and voltage requirements of your circuit to avoid damage or performance issues.

-

Use shielded cables: In applications sensitive to electromagnetic interference (EMI), such as audio systems, use shielded cables to minimize noise and interference.

-

Implement safety features: In critical applications, consider adding safety features such as limit switches or redundant controls to prevent accidents or equipment damage.

-

Plan for future adjustments: Position potentiometers in easily accessible locations to allow for future adjustments and maintenance.

-

Test and calibrate: After wiring the potentiometer, test the circuit and calibrate the potentiometer to ensure proper operation and accurate control.

Frequently Asked Questions (FAQ)

-

Q: Can I use a linear potentiometer for audio volume control?

A: While it’s possible to use a linear potentiometer for audio volume control, it’s generally recommended to use a logarithmic (audio taper) potentiometer. This is because the human ear perceives sound logarithmically, and a logarithmic potentiometer provides a more natural and intuitive volume control experience. -

Q: What happens if I connect the potentiometer terminals incorrectly?

A: Connecting the potentiometer terminals incorrectly may result in unexpected behavior or even damage to the potentiometer or other components in the circuit. Always double-check the terminal assignments and wiring diagram before making connections. -

Q: Can I use a potentiometer to control AC voltage?

A: Potentiometers are designed to work with DC Voltages. To control AC voltage, you would need to use a different type of device, such as a variable transformer or a solid-state AC voltage controller. -

Q: How do I determine the power rating of a potentiometer?

A: The power rating of a potentiometer is usually specified in the manufacturer’s datasheet. It indicates the maximum amount of power the potentiometer can dissipate without being damaged. To calculate the power dissipation, use the formula: P = V^2 / R, where P is the power in watts, V is the voltage across the potentiometer, and R is the total resistance of the potentiometer. -

Q: What is the difference between a rheostat and a potentiometer?

A: A rheostat is a two-terminal variable resistor that is used to control current in a circuit. It has a fixed resistive element and a wiper that contacts the element at one point. On the other hand, a potentiometer is a three-terminal device that can be used as a voltage divider or a variable resistor, offering more flexibility in circuit design.

Conclusion

Potentiometers are versatile components that play a crucial role in many electronic circuits, enabling users to control various parameters such as voltage, current, and resistance. By understanding the different types of potentiometers, their terminal assignments, and proper wiring techniques, you can effectively integrate potentiometers into your projects and achieve precise control over your circuits.

Remember to choose the appropriate potentiometer for your application, follow best practices for wiring and safety, and test your circuit thoroughly to ensure optimal performance. With the knowledge gained from this article, you should be well-equipped to tackle potentiometer wiring in your future electronic projects.

No responses yet