Introduction to Polyimide PCBs

Polyimide (PI) is a high-performance polymer material known for its excellent thermal stability, mechanical strength, and dielectric properties. When used as a substrate material for printed circuit boards (PCBs), polyimide offers several advantages over traditional materials like FR-4. Polyimide PCBs are widely used in demanding applications such as aerospace, military, and high-end electronics due to their ability to withstand extreme temperatures, harsh environments, and high-frequency signals.

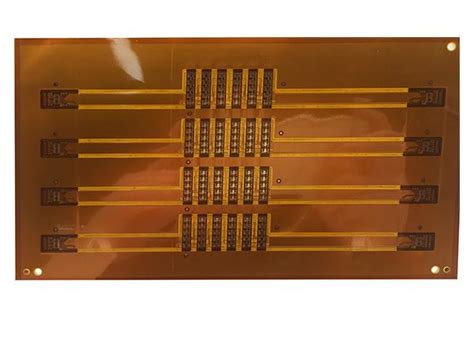

What is a Polyimide PCB?

A polyimide PCB is a printed circuit board that uses polyimide as the base material instead of the more common FR-4 (flame retardant-4) material. Polyimide is a synthetic polymer that belongs to a class of materials called thermoplastics. It is known for its exceptional thermal stability, chemical resistance, and mechanical strength.

Polyimide PCBs are fabricated using a similar process to traditional PCBs, but with some modifications to accommodate the unique properties of polyimide. The polyimide substrate is typically coated with a thin layer of copper, which is then etched to create the desired circuit pattern. The board may also undergo additional treatments such as via drilling, solder masking, and surface finishing.

Advantages of Polyimide PCBs

Polyimide PCBs offer several advantages over traditional FR-4 PCBs:

-

High temperature resistance: Polyimide can withstand temperatures up to 400°C, making it suitable for applications that involve high-temperature environments or thermal cycling.

-

Excellent dielectric properties: Polyimide has a low dielectric constant and low dissipation factor, which makes it ideal for high-frequency applications such as RF and microwave circuits.

-

Mechanical strength: Polyimide has a high tensile strength and flexural modulus, making it more durable and resistant to mechanical stress compared to FR-4.

-

Chemical resistance: Polyimide is resistant to most solvents, oils, and acids, making it suitable for use in harsh chemical environments.

-

Dimensional stability: Polyimide has a low coefficient of thermal expansion (CTE), which means it maintains its shape and size even under extreme temperature variations.

Types of Polyimide PCBs

There are several types of polyimide PCBs available, each with its own unique properties and applications.

Standard Polyimide PCBs

Standard polyimide PCBs are the most common type of polyimide PCBs. They are made using a single layer of polyimide substrate, typically with a thickness ranging from 0.001″ to 0.010″. Standard polyimide PCBs are suitable for most general-purpose applications that require high temperature resistance and dimensional stability.

Multilayer Polyimide PCBs

Multilayer polyimide PCBs are fabricated by stacking multiple layers of polyimide substrate, with each layer separated by a layer of copper. This allows for more complex circuit designs and higher component density compared to single-layer boards. Multilayer polyimide PCBs are commonly used in aerospace, military, and high-performance electronics applications.

Flexible Polyimide PCBs

Flexible polyimide PCBs are made using a thin, flexible polyimide substrate that can be bent or folded without damaging the circuit. This makes them ideal for applications that require a compact or irregular form factor, such as wearable electronics, medical devices, and aerospace systems. Flexible polyimide PCBs can be single-sided, double-sided, or multilayer, depending on the complexity of the circuit design.

Rigid-Flex Polyimide PCBs

Rigid-flex polyimide PCBs combine the benefits of both rigid and flexible PCBs by using a combination of rigid and flexible polyimide substrates. The rigid sections provide mechanical support and stability, while the flexible sections allow for bending and folding. Rigid-flex polyimide PCBs are commonly used in applications that require a mix of rigid and flexible components, such as aerospace, automotive, and medical devices.

Applications of Polyimide PCBs

Polyimide PCBs are used in a wide range of industries and applications, thanks to their unique properties and benefits.

Aerospace and Military

Polyimide PCBs are widely used in aerospace and military applications due to their ability to withstand extreme temperatures, vibrations, and shocks. They are used in avionics systems, satellite communications, radar systems, and missile guidance systems, among others.

Automotive Electronics

Polyimide PCBs are increasingly being used in automotive electronics, particularly in electric and hybrid vehicles. They are used in battery management systems, power inverters, and motor controllers, where high temperature resistance and reliability are critical.

Medical Devices

Polyimide PCBs are used in various medical devices, such as implantable devices, diagnostic equipment, and surgical instruments. They offer high biocompatibility, chemical resistance, and flexibility, making them suitable for use in the human body.

Industrial Automation

Polyimide PCBs are used in industrial automation systems, such as robotics, process control, and data acquisition. They offer high reliability and durability in harsh industrial environments, such as high temperatures, vibrations, and corrosive chemicals.

Consumer Electronics

Polyimide PCBs are used in high-end consumer electronics, such as smartphones, tablets, and wearable devices. They offer high performance, flexibility, and compact form factors, enabling the design of sleek and lightweight devices.

Comparison of Polyimide PCBs with Other Materials

Here is a table comparing the properties of polyimide PCBs with other common PCB materials:

| Property | Polyimide | FR-4 | Ceramic | Aluminum |

|---|---|---|---|---|

| Max. Operating Temp (°C) | 400 | 130 | 1000 | 150 |

| Dielectric Constant | 3.5 | 4.5 | 9.0 | N/A |

| Dissipation Factor | 0.002 | 0.02 | 0.001 | N/A |

| Tensile Strength (MPa) | 200 | 50 | 300 | 70 |

| CTE (ppm/°C) | 20 | 15 | 7 | 23 |

| Cost | High | Low | High | Medium |

As seen from the table, polyimide PCBs offer the highest temperature resistance and tensile strength among the compared materials. They also have a low dielectric constant and dissipation factor, making them suitable for high-frequency applications. However, they are also the most expensive material due to their unique properties and manufacturing process.

FAQ

Q1: What is the maximum operating temperature of polyimide PCBs?

A1: Polyimide PCBs can withstand temperatures up to 400°C, making them suitable for high-temperature applications.

Q2: Are polyimide PCBs more expensive than FR-4 PCBs?

A2: Yes, polyimide PCBs are generally more expensive than FR-4 PCBs due to their unique properties and manufacturing process.

Q3: Can polyimide PCBs be used in flexible applications?

A3: Yes, flexible polyimide PCBs are available and are commonly used in applications that require a compact or irregular form factor, such as wearable electronics and medical devices.

Q4: What industries commonly use polyimide PCBs?

A4: Polyimide PCBs are commonly used in aerospace, military, automotive, medical, industrial automation, and high-end consumer electronics industries.

Q5: What is the main advantage of using polyimide PCBs over other materials?

A5: The main advantage of using polyimide PCBs is their ability to withstand extreme temperatures and harsh environments while maintaining excellent dielectric and mechanical properties.

Conclusion

Polyimide PCBs offer a unique combination of properties that make them suitable for demanding applications in various industries. Their high temperature resistance, mechanical strength, and dielectric properties enable the design of reliable and high-performance electronic systems. While they may be more expensive than traditional FR-4 PCBs, the benefits they offer in terms of performance and reliability often justify the additional cost.

As technology continues to advance and the demand for high-performance electronics grows, polyimide PCBs are likely to play an increasingly important role in enabling the next generation of electronic devices and systems. From aerospace and military to medical devices and consumer electronics, polyimide PCBs are poised to deliver the performance and reliability needed to meet the challenges of the future.

No responses yet