What is PCB Wiring?

PCB wiring refers to the process of connecting electronic components to a printed circuit board using conductive paths, tracks, or signal traces etched from copper sheets laminated onto a non-conductive substrate. The purpose of PCB wiring is to create a functional electronic circuit by establishing electrical connections between components.

Tools and Materials Required for PCB Wiring

Before you start wiring your PCB, you’ll need to gather the necessary tools and materials. Here’s a list of essential items:

- Soldering iron

- Solder wire

- Flux

- Solder wick or desoldering pump

- Wire cutters

- Wire strippers

- Tweezers

- Multimeter

- Safety glasses

- Ventilated workspace

Choosing the Right Soldering Iron

When it comes to PCB wiring, having a high-quality soldering iron is crucial. Look for a soldering iron with adjustable temperature control and a fine tip for precise soldering. Some popular options include:

- Hakko FX-888D

- Weller WE1010

- X-Tronic 3020-XTS

Solder Wire and Flux

Solder wire is a metal alloy that melts when heated, allowing you to create electrical connections between components. When Choosing Solder wire, consider the following factors:

- Alloy composition (e.g., lead-free, tin-lead)

- Diameter (thinner wire for smaller components)

- Flux core (rosin, no-clean, water-soluble)

Flux is a chemical agent that helps remove oxidation and improves the flow of solder. It’s available in paste, liquid, and pen form.

PCB Wiring Techniques

There are several techniques you can use to wire your PCB, depending on the type of components and the complexity of the circuit. Let’s take a closer look at some common methods.

Through-Hole Soldering

Through-hole soldering involves inserting component leads through holes drilled in the PCB and soldering them to pads on the opposite side. This technique is suitable for larger components and is generally easier for beginners. Here’s a step-by-step guide:

- Insert the component leads through the designated holes in the PCB.

- Bend the leads slightly to hold the component in place.

- Apply a small amount of solder to the tip of the soldering iron.

- Touch the soldering iron to the pad and the component lead simultaneously.

- Feed solder into the joint until it forms a cone shape.

- Remove the soldering iron and let the joint cool.

Surface Mount Soldering

Surface mount soldering is used for smaller components that sit directly on the surface of the PCB. This technique requires more precision and skill than through-hole soldering. Here’s how to do it:

- Apply a small amount of solder paste to the pads using a stencil or syringe.

- Place the component onto the pads using tweezers.

- Preheat the PCB using a hot air gun or reflow oven.

- Apply heat to the component using a soldering iron or hot air gun until the solder melts and forms a connection.

- Remove the heat source and let the joint cool.

Wire Soldering

Wire soldering involves connecting wires directly to pads or pins on the PCB. This technique is often used for making modifications or repairs. Here’s how to do it:

- Strip a small amount of insulation from the end of the wire using wire strippers.

- Tin the exposed wire by applying a small amount of solder.

- Place the tinned wire onto the pad or pin.

- Touch the soldering iron to the wire and pad simultaneously.

- Feed solder into the joint until it forms a cone shape.

- Remove the soldering iron and let the joint cool.

Best Practices for PCB Wiring

To ensure the best results when wiring your PCB, follow these best practices:

- Always wear safety glasses to protect your eyes from solder splashes.

- Work in a well-ventilated area to avoid inhaling solder fumes.

- Keep your soldering iron clean and tinned for optimal heat transfer.

- Use the appropriate amount of solder for each joint – too little can result in a weak connection, while too much can cause short circuits.

- Inspect each joint after soldering to ensure a strong, shiny connection.

- Use a multimeter to test for continuity and short circuits before powering on your circuit.

Common PCB Wiring Mistakes and How to Avoid Them

Even experienced professionals can make mistakes when wiring PCBs. Here are some common issues and how to avoid them:

Cold Joints

Cold joints occur when the solder fails to melt completely, resulting in a weak, dull connection. To avoid cold joints:

- Ensure your soldering iron is set to the correct temperature.

- Keep the soldering iron tip clean and well-tinned.

- Apply heat to both the pad and the component lead simultaneously.

Solder Bridges

Solder bridges are unintentional connections between two or more pads, causing short circuits. To prevent solder bridges:

- Use the appropriate amount of solder for each joint.

- Keep the soldering iron tip clean and well-tinned.

- Use a solder wick or desoldering pump to remove excess solder.

Overheated Components

Applying too much heat to a component can cause damage, such as cracked casings or burned markings. To avoid overheating:

- Use the lowest temperature setting that allows for proper solder flow.

- Apply heat for the shortest time necessary to create a strong joint.

- Use a heat sink or thermal compound to dissipate heat from sensitive components.

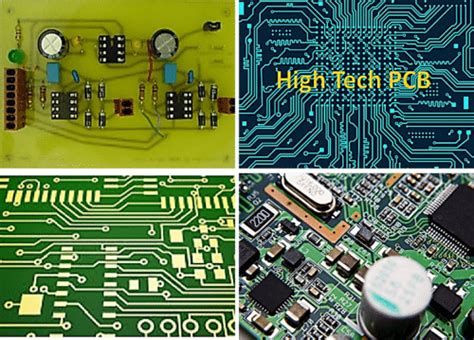

PCB Wiring Examples

To help illustrate the techniques and best practices discussed in this guide, let’s take a look at some examples of PCB wiring.

Example 1: Simple LED Circuit

In this example, we’ll wire a simple LED circuit using through-hole soldering.

Components:

– PCB

– LED

– 330Ω resistor

– Headers

Steps:

1. Insert the LED and resistor leads through their designated holes in the PCB.

2. Bend the leads slightly to hold the components in place.

3. Solder the LED and resistor leads to the pads on the opposite side of the PCB.

4. Insert the header pins into the PCB and solder them in place.

5. Test the circuit by applying power to the headers and verifying that the LED illuminates.

Example 2: Surface Mount IC

In this example, we’ll demonstrate surface mount soldering with an integrated circuit (IC).

Components:

– PCB

– Surface mount IC

– Solder paste

Steps:

1. Apply a small amount of solder paste to the IC pads using a stencil or syringe.

2. Place the IC onto the pads using tweezers, ensuring proper alignment.

3. Preheat the PCB using a hot air gun or reflow oven.

4. Apply heat to the IC using a soldering iron or hot air gun until the solder melts and forms a connection.

5. Remove the heat source and let the joints cool.

6. Inspect the joints for proper connection and alignment.

FAQ

-

What is the difference between lead-free and leaded solder?

Lead-free solder is an alloy that does not contain lead, while leaded solder contains a percentage of lead. Lead-free solder is preferred due to environmental and health concerns, but it typically requires higher soldering temperatures and can be more difficult to work with. -

How do I choose the right soldering iron tip size?

The size of the soldering iron tip depends on the size of the components and pads you’re working with. For smaller components and fine-pitch soldering, use a smaller tip (e.g., 0.5mm to 1mm). For larger components and pads, a larger tip (e.g., 2mm to 3mm) may be more suitable. -

Can I use a regular iron instead of a soldering iron?

No, a regular iron is not suitable for PCB wiring. Soldering Irons are specifically designed to reach and maintain the high temperatures needed to melt solder, and they have tips designed for precise application of heat to small areas. -

How often should I replace my soldering iron tip?

The lifespan of a soldering iron tip depends on usage and maintenance. With proper care, a high-quality tip can last for several months or even years. Replace your tip when it becomes heavily pitted, deformed, or no longer provides good heat transfer. -

What should I do if I accidentally create a solder bridge?

To remove a solder bridge, use a solder wick or desoldering pump to absorb the excess solder. Place the solder wick over the bridge and apply heat with your soldering iron. The solder should flow into the wick, removing the bridge. Alternatively, use a desoldering pump to suction the molten solder away from the bridge.

Conclusion

PCB wiring is a fundamental skill for anyone working with electronic circuits. By understanding the tools, techniques, and best practices involved in PCB wiring, you can create functional and reliable electronic devices. Remember to prioritize safety, work in a well-ventilated area, and always inspect your joints for proper connections. With practice and patience, you’ll be able to confidently tackle any PCB wiring project that comes your way.

No responses yet