What is PCB Trace Corrosion?

PCB trace corrosion is a common issue that affects the integrity and functionality of printed circuit boards (PCBs). It occurs when the conductive traces on the PCB surface are exposed to harsh environmental conditions, such as high humidity, temperature fluctuations, or the presence of corrosive substances. Over time, these factors can lead to the deterioration of the traces, resulting in reduced electrical conductivity, signal loss, and even complete circuit failure.

Types of PCB Trace Corrosion

There are several types of PCB trace corrosion, each with its own unique characteristics and causes:

-

Galvanic Corrosion: This type of corrosion occurs when two dissimilar metals are in contact with each other in the presence of an electrolyte (e.g., moisture). The more noble metal (cathode) remains protected, while the less noble metal (anode) corrodes.

-

Atmospheric Corrosion: Atmospheric corrosion is caused by exposure to airborne contaminants, such as sulfur dioxide, nitrogen oxides, and chlorides. These substances can react with the trace materials, leading to corrosion.

-

Chemical Corrosion: Chemical corrosion happens when the PCB traces come into contact with corrosive substances, such as acids, bases, or solvents. These chemicals can react with the trace materials, causing them to degrade.

-

Electrolytic Corrosion: Electrolytic corrosion occurs when an electrical current passes through an electrolyte, causing the dissolution of the metal traces. This type of corrosion is often seen in PCBs exposed to high humidity or liquid environments.

Factors Contributing to PCB Trace Corrosion

Several factors can contribute to the development of PCB trace corrosion:

Environmental Factors

-

Humidity: High humidity levels can lead to the formation of condensation on the PCB surface, which acts as an electrolyte and promotes corrosion.

-

Temperature: Extreme temperature fluctuations can cause the PCB materials to expand and contract, leading to stress and potential cracking of the traces. This can expose the underlying metal to corrosive elements.

-

Airborne Contaminants: Exposure to airborne pollutants, such as sulfur dioxide, nitrogen oxides, and chlorides, can accelerate the corrosion process.

Manufacturing Factors

-

Material Selection: Choosing inappropriate materials for the PCB substrate, traces, and finishes can increase the risk of corrosion. Some materials are more susceptible to corrosion than others.

-

Surface Finish: Inadequate or improper surface finishes can leave the traces vulnerable to corrosion. A high-quality surface finish, such as immersion gold or electroless nickel immersion gold (ENIG), can provide better protection against corrosion.

-

Solder Mask Application: A properly applied solder mask helps protect the traces from environmental factors. However, if the solder mask is too thin, has pinholes, or is damaged, it can expose the traces to corrosive elements.

Design Factors

-

Trace Spacing: Insufficient spacing between traces can lead to increased moisture retention and the formation of dendritic growth, which can cause short circuits and corrosion.

-

Trace Width: Traces that are too narrow may be more susceptible to corrosion due to their reduced cross-sectional area. Wider traces can better withstand the effects of corrosion.

-

Component Placement: Improper component placement can lead to areas of high moisture retention or exposure to corrosive substances, increasing the risk of corrosion.

Preventing PCB Trace Corrosion

To minimize the risk of PCB trace corrosion, several preventive measures can be implemented:

Material Selection

-

Choose Appropriate Substrate Materials: Select PCB substrate materials that are resistant to moisture absorption and have good dimensional stability, such as polyimide or FR-4 with a high glass transition temperature (Tg).

-

Use Corrosion-Resistant Trace Materials: Opt for trace materials that are less prone to corrosion, such as gold, palladium, or platinum. These materials have excellent corrosion resistance but may be more expensive than copper.

-

Select Suitable Surface Finishes: Choose surface finishes that provide good protection against corrosion, such as immersion gold, ENIG, or organic solderability preservatives (OSP). Avoid using finishes that are prone to corrosion, such as hot air solder leveling (HASL) with lead-free solder.

Manufacturing Process Optimization

-

Ensure Proper Solder Mask Application: Apply a uniform and sufficiently thick solder mask to protect the traces from environmental factors. Regularly inspect the solder mask for pinholes, cracks, or other defects.

-

Control Plating Process: Ensure that the plating process is well-controlled to achieve a consistent and defect-free surface finish. Regularly monitor the plating bath composition and maintain proper process parameters.

-

Implement Strict Cleanliness Standards: Maintain a clean manufacturing environment to minimize the presence of contaminants that can cause corrosion. Use appropriate cleaning agents and techniques to remove flux residues and other contaminants from the PCB surface.

Design Considerations

-

Maximize Trace Spacing: Ensure adequate spacing between traces to minimize moisture retention and the formation of dendritic growth. Follow the recommended spacing guidelines for the chosen PCB manufacturing process.

-

Use Appropriate Trace Widths: Design traces with sufficient width to improve their resistance to corrosion. Consider the current-carrying requirements and the available board space when selecting trace widths.

-

Optimize Component Placement: Place components in a way that minimizes exposure to corrosive environments and ensures proper airflow for heat dissipation. Avoid placing moisture-sensitive components in areas prone to condensation.

Conformal Coating

Applying a conformal coating to the PCB surface can provide an additional layer of protection against corrosion. Conformal coatings are thin, polymeric films that conform to the contours of the board and shield the traces from environmental factors. Common conformal coating materials include:

-

Acrylic: Acrylic coatings offer good moisture resistance and are easy to apply and repair. However, they have limited chemical resistance and may not be suitable for harsh environments.

-

Silicone: Silicone coatings provide excellent moisture and temperature resistance, as well as good flexibility. They are often used in high-temperature applications but may be more difficult to apply and repair compared to other coating types.

-

Polyurethane: Polyurethane coatings offer a balance of moisture, chemical, and abrasion resistance. They are commonly used in automotive and aerospace applications but may require a longer curing time compared to other coatings.

-

Parylene: Parylene coatings are applied through a vapor deposition process, resulting in a thin, uniform, and pinhole-free film. They provide excellent moisture, chemical, and dielectric resistance but may be more expensive than other coating options.

When selecting a conformal coating, consider the specific environmental conditions the PCB will be exposed to, as well as the ease of application, repair, and the overall cost.

Monitoring and Maintenance

Regular monitoring and maintenance of PCBs can help detect and address trace corrosion issues before they lead to complete circuit failure:

-

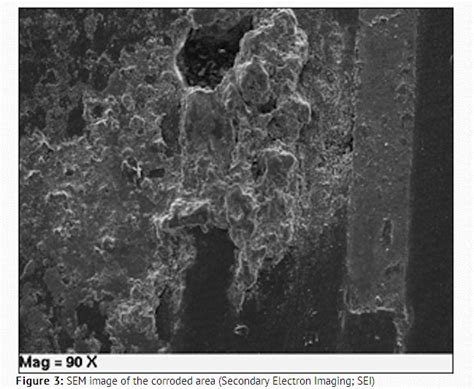

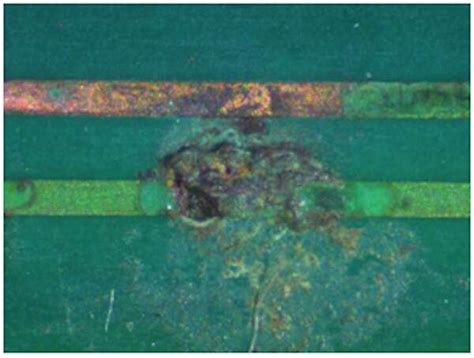

Visual Inspection: Regularly inspect the PCB surface for signs of corrosion, such as discoloration, pitting, or the presence of dendritic growth. Use a magnifying glass or microscope to examine the traces closely.

-

Electrical Testing: Perform periodic electrical tests to monitor the performance of the PCB. Changes in resistance, capacitance, or signal integrity may indicate the presence of corrosion.

-

Environmental Monitoring: Monitor the environmental conditions in which the PCB operates, including temperature, humidity, and the presence of corrosive substances. Use sensors or data loggers to track these parameters over time.

-

Cleaning and Repair: If corrosion is detected, clean the affected areas using appropriate methods, such as gentle abrasion or chemical cleaning agents. In some cases, localized repair of the corroded traces may be possible using conductive epoxies or other repair materials.

FAQ

-

What is the most common cause of PCB trace corrosion?

The most common cause of PCB trace corrosion is exposure to high humidity levels, which can lead to the formation of condensation on the PCB surface and promote corrosion. -

Can PCB trace corrosion be completely prevented?

While it may not be possible to completely prevent PCB trace corrosion, implementing proper design, manufacturing, and maintenance practices can significantly reduce the risk of corrosion and extend the lifespan of the PCB. -

How can I tell if my PCB is affected by trace corrosion?

Signs of PCB trace corrosion include discoloration, pitting, or the presence of dendritic growth on the trace surface. Electrical testing may also reveal changes in resistance, capacitance, or signal integrity, indicating the presence of corrosion. -

Can conformal coatings completely protect PCBs from corrosion?

Conformal coatings can provide an additional layer of protection against corrosion, but they are not a complete solution. Proper design, manufacturing, and maintenance practices must still be followed to minimize the risk of corrosion. -

How often should I perform maintenance on my PCBs to prevent corrosion?

The frequency of maintenance depends on the specific environmental conditions and the criticality of the PCB application. In general, it is recommended to perform visual inspections and electrical testing at least once a year, or more frequently if the PCB is exposed to harsh environments or critical applications.

| Factor | Influence on PCB Trace Corrosion |

|---|---|

| Humidity | High humidity levels can lead to condensation on the PCB surface, promoting corrosion. |

| Temperature | Extreme temperature fluctuations can cause stress and cracking of the traces, exposing them to corrosive elements. |

| Airborne Contaminants | Exposure to pollutants like sulfur dioxide, nitrogen oxides, and chlorides can accelerate the corrosion process. |

| Material Selection | Choosing inappropriate materials for the PCB substrate, traces, and finishes can increase the risk of corrosion. |

| Surface Finish | Inadequate or improper surface finishes can leave the traces vulnerable to corrosion. |

| Solder Mask Application | A properly applied solder mask helps protect the traces from environmental factors, while defects can expose the traces. |

| Trace Spacing | Insufficient spacing between traces can lead to increased moisture retention and the formation of dendritic growth. |

| Trace Width | Traces that are too narrow may be more susceptible to corrosion due to their reduced cross-sectional area. |

| Component Placement | Improper component placement can lead to areas of high moisture retention or exposure to corrosive substances. |

By understanding these factors and implementing appropriate preventive measures, designers and manufacturers can significantly reduce the risk of PCB trace corrosion and ensure the long-term reliability of their electronic devices.

No responses yet