What is a PCB Gerber Converter?

A PCB Gerber Converter is a software tool that converts PCB design files into the industry-standard Gerber format, which is used by PCB manufacturers to fabricate printed circuit boards. Gerber files contain all the necessary information to manufacture a PCB, including the copper layers, solder mask, silkscreen, and drill data.

PCB Gerber Converters take the output files from PCB design software, such as Altium Designer, Eagle, or KiCad, and convert them into Gerber files that can be sent to a PCB manufacturer for fabrication. This process ensures that the PCB design is accurately translated into the physical board, minimizing the risk of manufacturing errors and delays.

Key Features of PCB Gerber Converters

-

Compatibility: A good PCB Gerber Converter should be compatible with a wide range of PCB design software, including popular tools like Altium Designer, Eagle, KiCad, and OrCAD.

-

Accuracy: The converter should accurately translate the PCB design files into Gerber format, preserving all the necessary information for manufacturing, such as trace widths, pad sizes, and drill holes.

-

Customization: Some PCB Gerber Converters offer customization options, allowing users to adjust settings such as unit of measurement, aperture size, and file naming conventions to meet their specific requirements.

-

Error Checking: Advanced PCB Gerber Converters include error checking features that can identify potential issues in the PCB design, such as overlapping traces or missing connections, before the files are sent for manufacturing.

-

Ease of Use: A user-friendly interface and clear documentation make it easier for designers to use the converter effectively, even if they are not familiar with the Gerber file format.

The Importance of Gerber Files in PCB Manufacturing

Gerber files are the industry standard for PCB fabrication, and they play a crucial role in ensuring the accuracy and reliability of the manufacturing process. Here are some key reasons why Gerber files are essential:

-

Standardization: Gerber files provide a standardized format for communicating PCB design information to manufacturers, ensuring that all the necessary data is included and can be interpreted correctly.

-

Accuracy: By using Gerber files, PCB designers can ensure that their designs are accurately translated into the physical board, minimizing the risk of manufacturing errors and reducing the need for costly revisions.

-

Efficiency: Gerber files streamline the PCB manufacturing process by providing a clear and concise set of instructions for fabrication, reducing the time and effort required for communication between designers and manufacturers.

-

Compatibility: The widespread adoption of Gerber files means that they are compatible with a wide range of PCB manufacturing equipment and processes, making it easier to find a suitable manufacturer for any given project.

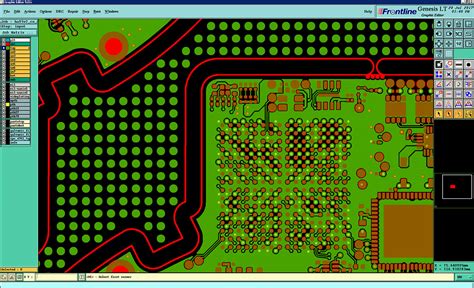

Gerber File Layers

A typical set of Gerber files for a PCB includes several layers, each representing a different aspect of the board design:

| Layer | Description |

|---|---|

| Top Copper | The copper traces and pads on the top side of the board |

| Bottom Copper | The copper traces and pads on the bottom side of the board |

| Top Solder Mask | The protective coating applied over the top copper layer, with openings for pads and exposed traces |

| Bottom Solder Mask | The protective coating applied over the bottom copper layer, with openings for pads and exposed traces |

| Top Silkscreen | The text and symbols printed on the top side of the board for component identification and assembly instructions |

| Bottom Silkscreen | The text and symbols printed on the bottom side of the board for component identification and assembly instructions |

| Drill Data | The locations and sizes of all the drilled holes in the board, including component mounting holes and vias |

How to Use a PCB Gerber Converter

Using a PCB Gerber Converter typically involves the following steps:

-

Design your PCB: Create your PCB design using your preferred PCB design software, such as Altium Designer, Eagle, or KiCad.

-

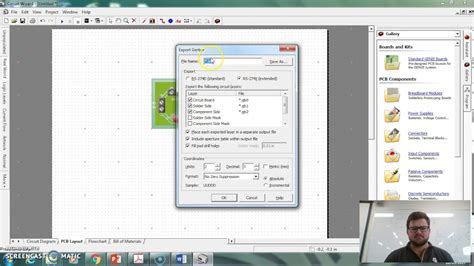

Generate output files: Once your design is complete, generate the output files from your PCB design software. These files will typically include Gerber files (.gbr) for each layer of the board, as well as drill files (.drl) containing information about the drilled holes.

-

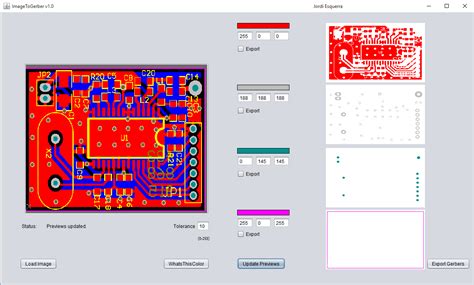

Import files into the converter: Open your PCB Gerber Converter and import the output files generated from your PCB design software. Most converters will automatically detect the file format and layer information.

-

Customize settings (optional): If necessary, adjust any settings in the converter, such as unit of measurement, aperture size, or file naming conventions, to meet your specific requirements or the requirements of your chosen PCB manufacturer.

-

Convert files: Initiate the conversion process, which will translate your PCB design files into the standard Gerber format. This process typically takes only a few seconds, depending on the complexity of your design.

-

Verify the output: After the conversion is complete, inspect the generated Gerber files to ensure that all the necessary information has been included and that there are no obvious errors or discrepancies.

-

Send files to manufacturer: Package the Gerber files and send them to your chosen PCB manufacturer for fabrication. Most manufacturers will accept Gerber files via email or through an online submission portal.

Tips for Successful PCB Gerber Conversion

-

Ensure design accuracy: Before converting your PCB design files, double-check your design for any errors or inconsistencies that could lead to manufacturing issues. Use your PCB design software’s built-in error checking tools to identify and resolve any problems.

-

Choose the right converter: Select a PCB Gerber Converter that is compatible with your PCB design software and offers the features and customization options you need. Consider factors such as ease of use, accuracy, and error checking capabilities.

-

Communicate with your manufacturer: Consult with your chosen PCB manufacturer to ensure that you are providing all the necessary files and information they require for fabrication. Some manufacturers may have specific requirements or preferences for Gerber file formatting or naming conventions.

-

Verify the output: Always inspect the generated Gerber files after conversion to ensure that they accurately represent your PCB design. Look for any missing or incorrect information, such as incorrect trace widths or missing drill holes.

-

Keep a backup: Store a copy of your original PCB design files and the generated Gerber files in a safe location, such as a cloud storage service or an external hard drive. This will ensure that you have a backup in case of data loss or if revisions to the design are necessary.

FAQ

1. What is the difference between Gerber files and other PCB design file formats?

Gerber files are the industry standard for PCB fabrication and are specifically designed to communicate PCB design information to manufacturers. Other file formats, such as ODB++ or IPC-2581, may contain additional information or be used for specific purposes, but Gerber files are the most widely accepted and supported format for PCB manufacturing.

2. Can I use a PCB Gerber Converter with any PCB design software?

Most PCB Gerber Converters are compatible with a wide range of popular PCB design software, such as Altium Designer, Eagle, and KiCad. However, it’s essential to check the converter’s specifications to ensure that it supports your specific software and version.

3. Are there any limitations to using a PCB Gerber Converter?

PCB Gerber Converters are generally very reliable and accurate, but there may be some limitations depending on the complexity of your PCB design or the specific requirements of your chosen manufacturer. In some cases, you may need to manually adjust certain settings or provide additional information to ensure a successful conversion.

4. What should I do if I encounter errors during the Gerber conversion process?

If you encounter errors during the Gerber conversion process, first check that you have imported the correct files and that your PCB design is free of errors. If the problem persists, consult the documentation or support resources provided by your PCB Gerber Converter software. You may also need to contact your PCB manufacturer for guidance on their specific requirements.

5. Can I edit Gerber files after they have been generated?

While it is possible to edit Gerber files using specialized software, it is generally not recommended unless you have experience working with the Gerber format. Any changes made to the Gerber files could potentially introduce errors or inconsistencies that could lead to manufacturing issues. If you need to make changes to your PCB design, it’s best to do so in your original PCB design software and then re-generate the Gerber files.

Conclusion

PCB Gerber Converters are essential tools for ensuring accurate and reliable PCB fabrication. By converting PCB design files into the industry-standard Gerber format, these converters help streamline the manufacturing process and minimize the risk of errors and delays.

When choosing a PCB Gerber Converter, consider factors such as compatibility, accuracy, customization options, and ease of use. By selecting the right converter and following best practices for PCB design and file preparation, you can ensure that your PCB projects are successfully manufactured to your specifications.

As PCB design and manufacturing technologies continue to evolve, the role of PCB Gerber Converters in ensuring standardization and reliability will remain crucial. By understanding the importance of Gerber files and how to effectively use PCB Gerber Converters, PCB designers and manufacturers can work together to create high-quality, reliable electronic products that meet the demands of today’s increasingly complex applications.

No responses yet