Introduction to PCB Thermal Analysis

Printed Circuit Boards (PCBs) are essential components in modern electronics, serving as the foundation for electrical connections and component placement. As electronic devices become more complex and compact, managing heat dissipation becomes a critical factor in ensuring optimal performance and reliability. This is where PCB thermal analysis software comes into play.

PCB thermal analysis is the process of simulating and analyzing the thermal behavior of a PCB design to identify potential heat-related issues and optimize the board’s thermal management. By employing advanced software tools, engineers can predict and mitigate thermal problems early in the design phase, saving time and resources that would otherwise be spent on physical prototyping and testing.

Importance of Thermal Management in PCB Design

Effective thermal management is crucial for several reasons:

-

Component Reliability: Excessive heat can cause components to operate outside their specified temperature range, leading to reduced performance, premature failure, and decreased overall reliability.

-

Signal Integrity: High temperatures can affect the electrical properties of PCB materials, causing signal degradation and potentially leading to malfunctions.

-

Power Efficiency: Proper thermal management helps to minimize power losses and improve the overall power efficiency of the system.

-

Compliance with Standards: Many industries have specific thermal requirements that PCBs must meet to ensure safety and compliance with regulations.

By addressing thermal concerns during the design phase, engineers can create PCBs that are more reliable, efficient, and compliant with industry standards.

Key Features of PCB Thermal Analysis Software

PCB thermal analysis software offers a range of features to help engineers simulate and optimize the thermal performance of their designs. Some of the key features include:

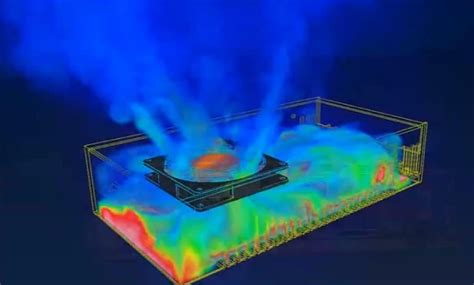

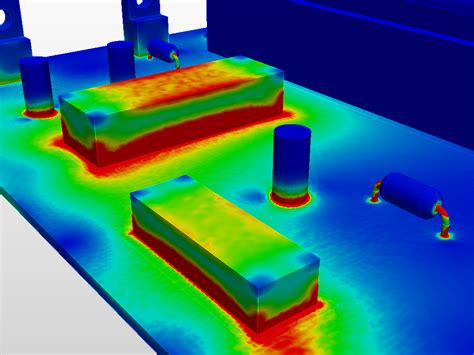

1. 3D Modeling and Visualization

Advanced PCB thermal analysis software allows users to create detailed 3D models of their PCB designs, including components, heat sinks, and enclosures. This enables engineers to visualize the thermal distribution across the board and identify hot spots that may require attention.

2. Finite Element Analysis (FEA)

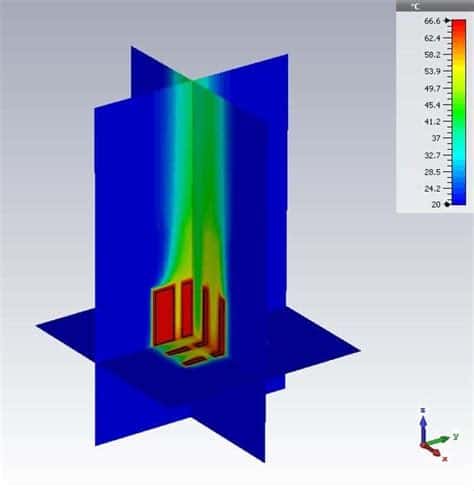

FEA is a numerical method used to solve complex heat transfer problems. PCB thermal analysis software employs FEA to discretize the PCB model into smaller elements and solve the heat transfer equations for each element. This provides accurate temperature predictions and helps engineers understand the thermal behavior of the board.

3. Steady-State and Transient Analysis

Thermal analysis software can perform both steady-state and transient simulations. Steady-state analysis determines the temperature distribution when the system reaches thermal equilibrium, while transient analysis examines the temperature changes over time, considering factors such as power cycling and environmental conditions.

4. Thermal Resistance Networks

Some PCB thermal analysis tools allow users to create thermal resistance networks, which represent the heat transfer paths between components, PCB layers, and the environment. This approach simplifies the analysis process and provides quick estimates of the thermal performance.

5. Parametric Studies and Optimization

Parametric studies enable engineers to investigate the impact of design changes on the thermal performance of the PCB. By varying parameters such as component placement, materials, and cooling solutions, engineers can optimize the design for better heat dissipation and overall performance.

Benefits of Using PCB Thermal Analysis Software

Incorporating PCB thermal analysis software into the design workflow offers several benefits:

-

Reduced Development Time and Costs: By identifying and addressing thermal issues early in the design phase, engineers can avoid costly design iterations and physical prototyping, ultimately reducing development time and expenses.

-

Improved Product Quality: Thermal analysis software helps engineers create PCBs with better thermal management, resulting in more reliable and efficient products.

-

Enhanced Collaboration: Many PCB thermal analysis tools integrate with other design software, allowing seamless data exchange between thermal, electrical, and mechanical domains. This facilitates collaboration among different engineering teams and streamlines the design process.

-

Competitive Advantage: By leveraging advanced thermal analysis capabilities, companies can differentiate themselves from competitors and deliver products with superior thermal performance and reliability.

Choosing the Right PCB Thermal Analysis Software

When selecting a PCB thermal analysis software, consider the following factors:

-

Compatibility: Ensure that the software is compatible with your existing PCB design tools and workflows.

-

Accuracy: Look for software that employs advanced numerical methods, such as FEA, to provide accurate temperature predictions.

-

Ease of Use: Choose a software with a user-friendly interface and intuitive workflows to minimize the learning curve and increase productivity.

-

Customization: Consider software that allows customization and scripting to automate repetitive tasks and adapt to your specific design requirements.

-

Support and Training: Evaluate the level of support and training provided by the software vendor to ensure that you can effectively implement and utilize the tool.

Case Studies: Successful Application of PCB Thermal Analysis Software

Several industries have successfully applied PCB thermal analysis software to improve their designs and overcome thermal challenges. Here are a few case studies:

1. Automotive Electronics

In the automotive industry, PCBs are subjected to harsh environmental conditions and must operate reliably under extreme temperatures. A leading automotive electronics manufacturer used PCB thermal analysis software to optimize the thermal design of a power control module. By simulating various cooling solutions and component placements, they were able to reduce the maximum temperature by 20°C, ensuring reliable operation and extending the product’s lifespan.

2. Aerospace and Defense

Aerospace and defense applications often require PCBs to function in demanding environments, including high altitudes and extreme temperature fluctuations. An aerospace company employed PCB thermal analysis software to design a high-performance radar system. Through extensive thermal simulations, they optimized the PCB layout and cooling system, resulting in a 30% reduction in thermal resistance and improved signal integrity.

3. Consumer Electronics

In the fast-paced world of consumer electronics, product development cycles are short, and thermal management is critical for delivering reliable and compact devices. A smartphone manufacturer utilized PCB thermal analysis software to optimize the thermal design of their latest flagship device. By simulating various heat dissipation strategies, they were able to minimize hot spots and ensure optimal performance, even under heavy use conditions.

Best Practices for Effective PCB Thermal Analysis

To get the most out of PCB thermal analysis software, follow these best practices:

-

Start Early: Integrate thermal analysis into the early stages of the design process to identify and address issues before they become more difficult and expensive to resolve.

-

Validate Models: Ensure that your 3D models accurately represent the physical PCB, including material properties, component placement, and boundary conditions.

-

Perform Sensitivity Analysis: Conduct sensitivity studies to understand how design changes impact thermal performance, and use this information to make informed design decisions.

-

Collaborate with Other Domains: Work closely with electrical and mechanical engineers to ensure that thermal considerations are integrated into the overall design process.

-

Verify with Physical Testing: While PCB thermal analysis software provides valuable insights, it’s essential to validate the simulation results with physical testing to ensure the accuracy of the models and predictions.

Future Trends in PCB Thermal Analysis Software

As electronic devices continue to evolve, so will the capabilities of PCB thermal analysis software. Some of the future trends to watch for include:

-

Integration with AI and Machine Learning: Artificial intelligence and machine learning algorithms can be employed to automate design optimization and identify thermal issues more efficiently.

-

Cloud-Based Solutions: Cloud-based PCB thermal analysis software will enable collaborative design and provide access to high-performance computing resources for more complex simulations.

-

Multiphysics Analysis: Integrating thermal analysis with other physics domains, such as structural and electromagnetic simulations, will provide a more comprehensive understanding of the PCB’s overall performance.

-

Virtual Reality (VR) and Augmented Reality (AR): VR and AR technologies can be used to visualize and interact with 3D thermal models, enhancing the user experience and facilitating better design insights.

Frequently Asked Questions (FAQ)

1. What is the difference between steady-state and transient thermal analysis?

Steady-state thermal analysis determines the temperature distribution when the system reaches thermal equilibrium, assuming constant power dissipation and boundary conditions. Transient analysis, on the other hand, examines the temperature changes over time, considering factors such as power cycling and varying environmental conditions.

2. How accurate are the temperature predictions from PCB thermal analysis software?

The accuracy of temperature predictions depends on various factors, such as the quality of the 3D model, the accuracy of material properties, and the boundary conditions. Modern PCB thermal analysis software employs advanced numerical methods, such as FEA, to provide accurate results. However, it’s essential to validate the simulation results with physical testing to ensure the accuracy of the models and predictions.

3. Can PCB thermal analysis software optimize the placement of components?

Yes, many PCB thermal analysis tools offer optimization features that can help engineers determine the best placement of components for improved thermal performance. By running parametric studies and analyzing the impact of component placement on temperature distribution, engineers can make informed decisions to optimize the PCB layout.

4. How does PCB thermal analysis software handle complex geometries and materials?

Advanced PCB thermal analysis software can handle complex geometries and materials by using 3D modeling and finite element analysis (FEA). The software discretizes the PCB model into smaller elements and assigns appropriate material properties to each element. This allows for accurate simulation of heat transfer, even in complex structures with multiple materials.

5. Can PCB thermal analysis software integrate with other design tools?

Yes, many PCB thermal analysis tools offer integration with other design software, such as PCB layout and CAD tools. This integration allows for seamless data exchange between thermal, electrical, and mechanical domains, facilitating collaboration among different engineering teams and streamlining the design process.

Conclusion

PCB thermal analysis software is a crucial tool for managing heat dissipation and ensuring the reliability and performance of modern electronic devices. By leveraging advanced features such as 3D modeling, finite element analysis, and parametric studies, engineers can identify and mitigate thermal issues early in the design phase, reducing development time and costs while improving product quality.

When selecting a PCB thermal analysis software, consider factors such as compatibility, accuracy, ease of use, customization options, and support. By following best practices and staying up-to-date with future trends, engineers can effectively utilize PCB thermal analysis software to create innovative and thermally optimized electronic products.

| Feature | Description |

|---|---|

| 3D Modeling and Visualization | Create detailed 3D models of PCB designs, including components, heat sinks, and enclosures. |

| Finite Element Analysis (FEA) | Discretize the PCB model into smaller elements and solve heat transfer equations for accurate temperature predictions. |

| Steady-State and Transient Analysis | Perform both steady-state and transient simulations to analyze thermal equilibrium and temperature changes over time. |

| Thermal Resistance Networks | Represent heat transfer paths between components, PCB layers, and the environment for quick thermal performance estimates. |

| Parametric Studies and Optimization | Investigate the impact of design changes on thermal performance and optimize the design for better heat dissipation. |

By incorporating these key features, PCB thermal analysis software empowers engineers to create thermally optimized and reliable electronic products, driving innovation and success in various industries.

No responses yet