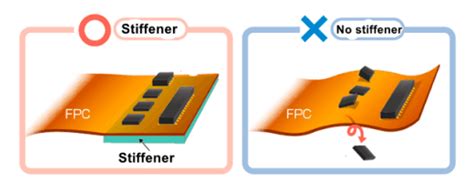

What is a PCB Stiffener?

A PCB stiffener, also known as a board stiffener or reinforcement plate, is a mechanical support component used to enhance the rigidity and durability of flexible and rigid-flex printed circuit boards (PCBs). These stiffeners are typically made from materials such as aluminum, stainless steel, or fiberglass, and are attached to the PCB using adhesives or fasteners.

The primary purpose of a PCB stiffener is to prevent the board from bending, warping, or twisting during the manufacturing process, assembly, and throughout its operational life. By providing additional support, stiffeners help maintain the PCB’s structural integrity, ensuring proper component placement, and minimizing the risk of damage due to physical stress.

Why are PCB Stiffeners Important?

PCB stiffeners play a crucial role in the performance and longevity of flexible and rigid-flex PCBs. These types of PCBs are increasingly popular in various industries, including aerospace, automotive, medical, and consumer electronics, due to their ability to conform to unique shapes and save space in compact designs.

However, the flexibility of these PCBs also makes them more susceptible to mechanical stress and deformation. Excessive bending or twisting can cause damage to the copper traces, solder joints, and mounted components, leading to circuit failures and reduced reliability.

By incorporating PCB stiffeners, designers can:

- Improve the overall structural integrity of the PCB

- Protect sensitive components from mechanical stress

- Ensure proper alignment and spacing of components during assembly

- Enhance the PCB’s ability to withstand vibration and shock

- Increase the PCB’s lifespan and reliability

Types of PCB Stiffeners

There are several types of PCB stiffeners available, each with its own characteristics and applications:

Aluminum Stiffeners

Aluminum stiffeners are the most common type due to their excellent strength-to-weight ratio, good thermal conductivity, and relatively low cost. They are lightweight, easy to machine, and can be anodized for improved corrosion resistance. Aluminum stiffeners are suitable for a wide range of applications, from consumer electronics to industrial equipment.

Stainless Steel Stiffeners

Stainless steel stiffeners offer superior strength and durability compared to aluminum. They are ideal for applications that require high levels of mechanical stability and resistance to harsh environmental conditions, such as extreme temperatures, moisture, and chemicals. However, stainless steel stiffeners are heavier and more expensive than aluminum.

Fiberglass Stiffeners

Fiberglass stiffeners, also known as FR4 stiffeners, are made from the same material as the PCB substrate itself. They offer good electrical insulation properties and have a coefficient of thermal expansion (CTE) similar to that of the PCB, which helps minimize stress caused by temperature fluctuations. Fiberglass stiffeners are lightweight and cost-effective, making them suitable for general-purpose applications.

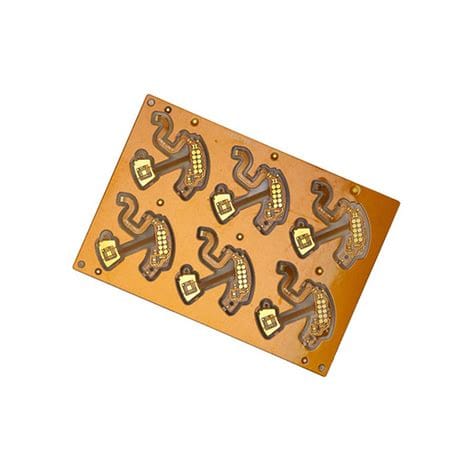

Custom Stiffeners

In some cases, custom stiffeners may be required to accommodate unique PCB designs or specific application requirements. These stiffeners can be fabricated from various materials and can be shaped to fit the specific contours of the PCB. Custom stiffeners may also incorporate additional features, such as heat sinks or EMI shielding, to enhance the PCB’s overall performance.

Designing with PCB Stiffeners

When designing a flexible or rigid-flex PCB that incorporates stiffeners, several factors must be considered to ensure optimal performance and reliability:

Stiffener Material Selection

The choice of stiffener material depends on the specific requirements of the application, such as strength, weight, thermal conductivity, and cost. Designers should consider the environmental conditions the PCB will be exposed to, as well as any special requirements, such as electrical insulation or EMI shielding.

Stiffener Placement

The placement of the stiffener on the PCB is crucial for effective support and protection. Stiffeners should be positioned in areas that are most susceptible to mechanical stress, such as regions with high component density or areas that will be subject to bending or flexing. Designers should also consider the placement of the stiffener in relation to the PCB’s mounting points and connectors.

Stiffener Thickness

The thickness of the stiffener is another important consideration. Thicker stiffeners offer greater rigidity and support, but they also add weight and may increase the overall thickness of the PCB assembly. Designers must strike a balance between the required level of support and the space and weight constraints of the application.

Attachment Method

PCB stiffeners can be attached to the board using various methods, including adhesives, screws, or rivets. The choice of attachment method depends on factors such as the size and weight of the stiffener, the expected level of mechanical stress, and the ease of assembly and disassembly. Adhesive bonding is a popular choice for smaller stiffeners, while screws or rivets may be preferred for larger or heavier stiffeners.

Thermal Management

In some cases, PCB stiffeners can also serve as heat sinks to help dissipate heat generated by components on the board. When designing a stiffener for thermal management, designers must consider factors such as the thermal conductivity of the stiffener material, the size and shape of the stiffener, and the placement of the stiffener in relation to the heat-generating components.

Manufacturing and Assembly Considerations

When manufacturing and assembling PCBs with stiffeners, there are several key considerations to ensure a successful outcome:

Stiffener Fabrication

PCB stiffeners are typically fabricated using CNC machining, stamping, or laser cutting, depending on the material and design complexity. It is important to ensure that the stiffener dimensions and tolerances are accurately specified and maintained throughout the fabrication process to ensure a proper fit with the PCB.

Surface Preparation

Before attaching the stiffener to the PCB, both surfaces must be properly cleaned and prepared to ensure good adhesion. This may involve degreasing, abrading, or applying a surface treatment to improve bonding. The specific surface preparation requirements will depend on the stiffener material and the chosen attachment method.

Alignment and Fixturing

During assembly, it is crucial to ensure precise alignment between the PCB and the stiffener. Misalignment can result in uneven stress distribution, component shifting, or difficulties in final assembly. Custom fixturing or alignment tools may be necessary to maintain proper positioning throughout the attachment process.

Process Control

Strict process control is essential during PCB assembly to ensure consistent and reliable results. This includes monitoring and controlling factors such as adhesive application, curing time and temperature, and fastener torque (if applicable). Proper process documentation and operator training are also important to maintain quality and reproducibility.

Case Studies

To illustrate the practical applications of PCB stiffeners, let’s consider a few real-world examples:

Aerospace Electronics

In the aerospace industry, PCBs are subjected to extreme environmental conditions, including high levels of vibration, shock, and temperature fluctuations. A manufacturer of avionics equipment used rigid-flex PCBs with aluminum stiffeners to ensure the reliability and durability of their products. The stiffeners were strategically placed to reinforce critical areas of the PCB and protect sensitive components from mechanical stress during flight.

Medical Devices

A medical device company developed a compact, wearable monitor that required a flexible PCB to fit within the device’s curved housing. To prevent the PCB from flexing excessively and damaging the components, they incorporated a thin, laser-cut stainless steel stiffener. The stiffener provided the necessary support without adding significant weight or bulk to the device.

Automotive Electronics

An automotive electronics supplier used PCB stiffeners to enhance the reliability of their products in the harsh under-hood environment. They selected fiberglass stiffeners for their PCBs to provide both mechanical support and electrical insulation. The stiffeners helped prevent PCB Warpage and ensured proper component alignment during the high-temperature solder reflow process.

Frequently Asked Questions (FAQ)

1. Can PCB stiffeners be used with both flexible and rigid-flex PCBs?

Yes, PCB stiffeners can be used with both flexible and rigid-flex PCBs. In fact, they are particularly beneficial for these types of PCBs, as they help maintain the structural integrity of the flexible regions and prevent excessive bending or twisting.

2. How do I choose the right stiffener material for my application?

The choice of stiffener material depends on several factors, including the required level of support, the environmental conditions the PCB will be exposed to, and any specific requirements such as electrical insulation or thermal conductivity. Aluminum is a popular choice for general-purpose applications, while stainless steel is often used in more demanding environments. Fiberglass stiffeners are suitable when electrical insulation is a priority.

3. Can PCB stiffeners be used for thermal management?

Yes, in some cases, PCB stiffeners can be designed to serve as heat sinks, helping to dissipate heat generated by components on the board. When using a stiffener for thermal management, it is important to consider factors such as the thermal conductivity of the stiffener material and the placement of the stiffener in relation to the heat-generating components.

4. How are PCB stiffeners typically attached to the board?

PCB stiffeners can be attached to the board using various methods, including adhesives, screws, or rivets. Adhesive bonding is a popular choice for smaller stiffeners, as it provides a strong, uniform bond without adding significant weight or thickness to the assembly. Screws or rivets may be preferred for larger or heavier stiffeners, or when easy disassembly is required.

5. Are there any design guidelines for incorporating PCB stiffeners?

When designing a PCB with stiffeners, it is important to consider factors such as the placement of the stiffener, its thickness, and the attachment method. Stiffeners should be positioned in areas that are most susceptible to mechanical stress, and their thickness should be selected to provide the necessary level of support without adding excessive weight or bulk. The attachment method should be chosen based on the size and weight of the stiffener, the expected level of mechanical stress, and the ease of assembly and disassembly.

Conclusion

PCB stiffeners are an essential component in the design and manufacture of flexible and rigid-flex PCBs. By providing mechanical support and reinforcement, stiffeners help maintain the structural integrity of the PCB, protect sensitive components from damage, and enhance the overall reliability and durability of the electronic assembly.

When designing PCBs with stiffeners, it is important to consider factors such as the choice of stiffener material, placement, thickness, and attachment method. By carefully selecting and integrating stiffeners into the PCB design, engineers can create more robust and reliable electronic products that can withstand the demands of a wide range of applications, from consumer electronics to aerospace and medical devices.

As the use of flexible and rigid-flex PCBs continues to grow across various industries, the role of PCB stiffeners in ensuring the performance and longevity of these advanced electronic assemblies will only become more critical. By understanding the principles and best practices of designing with PCB stiffeners, engineers can unlock new possibilities for innovation and reliability in the ever-evolving world of electronics.

No responses yet