What is PCB Simulation Software?

PCB simulation software is a type of computer-aided design (CAD) tool that enables engineers to create virtual models of printed circuit boards and simulate their behavior under various conditions. These tools allow designers to test and optimize their designs for factors such as signal integrity, power distribution, electromagnetic compatibility (EMC), and thermal management, among others.

By using PCB simulators, engineers can identify and correct potential issues early in the design process, reducing the risk of costly mistakes and delays during manufacturing. Simulation also enables designers to experiment with different materials, components, and layouts to find the optimal configuration for their specific application.

Key Features of PCB Simulation Software

While the exact features and capabilities may vary between different PCB simulation tools, most of them share some common functionalities:

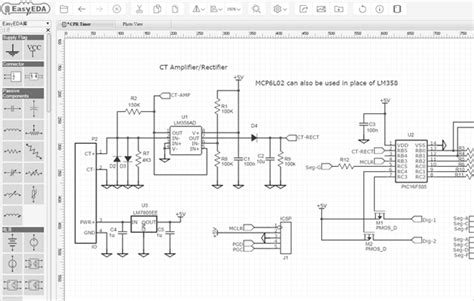

Schematic Capture

The first step in PCB design is creating a schematic diagram that represents the electrical connections between components. PCB simulation software typically includes a schematic capture tool that allows designers to draw and edit these diagrams using a graphical user interface (GUI).

PCB Layout

Once the schematic is complete, the next step is to create the physical layout of the PCB. This involves placing components on the board, routing traces between them, and defining the board’s shape and size. PCB simulators provide a range of tools for automated and manual layout, as well as design rule checking (DRC) to ensure the layout meets manufacturing requirements.

Signal Integrity Analysis

Signal integrity (SI) refers to the quality and reliability of electrical signals transmitted through the PCB. Factors such as trace length, impedance, crosstalk, and reflections can all affect signal integrity. PCB simulation software includes tools for analyzing and optimizing SI, such as time-domain and frequency-domain simulations, eye diagrams, and impedance matching.

Power Integrity Analysis

Power integrity (PI) is concerned with the distribution of power throughout the PCB, ensuring that each component receives the correct voltage and current. PCB simulators can analyze factors such as voltage drop, current density, and decoupling capacitor placement to optimize power delivery and minimize noise.

Electromagnetic Compatibility Analysis

Electromagnetic compatibility (EMC) refers to the ability of electronic devices to operate without causing or being affected by electromagnetic interference (EMI). PCB simulation software can simulate the electromagnetic fields generated by the board and its components, helping designers to identify and mitigate potential EMC issues.

Thermal Analysis

Thermal management is crucial for ensuring the reliability and longevity of electronic devices. PCB simulators can analyze the heat generated by components and the thermal conductivity of the board material, helping designers to optimize the placement of heat-sensitive components and cooling solutions.

3D Visualization

Many PCB simulation tools offer 3D visualization capabilities, allowing designers to view their boards from different angles and check for mechanical clearances and interference. Some tools also support the import and export of 3D models for integration with mechanical CAD (MCAD) software.

Benefits of Using PCB Simulation Software

Using PCB simulation software offers numerous benefits for engineers and companies involved in electronic product development:

-

Faster time-to-market: By identifying and correcting issues early in the design process, PCB simulators can help reduce the number of physical prototypes required, speeding up the overall development cycle.

-

Cost savings: Catching and fixing problems before manufacturing can save significant costs associated with redesigns, material waste, and production delays.

-

Improved reliability: Simulation allows designers to optimize their boards for signal integrity, power delivery, and thermal management, resulting in more reliable and robust products.

-

Enhanced collaboration: Many PCB simulation tools support collaboration features, such as version control and design sharing, making it easier for teams to work together on complex projects.

-

Competitive advantage: By leveraging the power of simulation, companies can create more innovative, high-performance products that stand out in the market.

Popular PCB Simulation Software Options

There are numerous PCB simulation software options available, ranging from free and open-source tools to high-end commercial solutions. Some popular choices include:

| Software | Developer | Key Features |

|---|---|---|

| Altium Designer | Altium | Schematic capture, PCB layout, 3D visualization, signal and power integrity analysis |

| OrCAD | Cadence | Schematic capture, PCB layout, SI/PI analysis, constraint-driven design |

| PADS | Mentor Graphics | Schematic capture, PCB layout, constraint management, design for manufacturing (DFM) |

| KiCad | Open-source | Schematic capture, PCB layout, 3D viewer, integrated SPICE simulator |

| Eagle | Autodesk | Schematic capture, PCB layout, real-time DRC, extensive component libraries |

Choosing the Right PCB Simulation Software

When selecting a PCB simulation tool, consider the following factors:

-

Functionality: Ensure the software has the features and capabilities needed for your specific design requirements, such as signal integrity analysis or thermal simulation.

-

Ease of use: Look for tools with intuitive interfaces and workflows that can be easily adopted by your team.

-

Integration: Consider how well the software integrates with other tools in your design flow, such as CAD systems or version control platforms.

-

Scalability: Choose a tool that can scale with your needs, whether you’re working on simple boards or complex, high-density designs.

-

Support and training: Evaluate the level of technical support and training resources provided by the software vendor, as well as the availability of online communities and forums.

FAQ

1. What is the difference between PCB design and PCB simulation software?

PCB design software focuses on creating the schematic and physical layout of the board, while PCB simulation software is used to test and optimize the design for factors such as signal integrity, power delivery, and electromagnetic compatibility.

2. Can PCB simulation completely replace physical prototyping?

While PCB simulation can significantly reduce the need for physical prototypes, it is not a complete replacement. Some issues, such as manufacturing defects or real-world environmental factors, may not be fully captured in the simulation.

3. How much does PCB simulation software cost?

The cost of PCB simulation software varies widely, from free and open-source tools to high-end commercial solutions that can cost tens of thousands of dollars. The price typically depends on the features, performance, and level of support provided.

4. What skills are required to use PCB simulation software effectively?

To use PCB simulation software effectively, engineers should have a strong understanding of electronic design principles, including circuit theory, signal integrity, and electromagnetic compatibility. Familiarity with CAD tools and programming languages can also be beneficial.

5. How do I choose the right PCB simulation software for my project?

When choosing PCB simulation software, consider factors such as the specific requirements of your project, the ease of use and learning curve of the tool, its integration with other software in your design flow, and the level of support and resources provided by the vendor.

Conclusion

PCB simulation software is an essential tool for engineers involved in the design and development of electronic products. By allowing designers to test and optimize their boards virtually, these tools can help reduce costs, improve reliability, and accelerate time-to-market. When selecting a PCB simulator, it’s important to consider factors such as functionality, ease of use, integration, scalability, and support to ensure the best fit for your specific needs and requirements.

As electronic devices continue to become more complex and demanding, the role of PCB simulation software in the design process will only grow in importance. By leveraging the power of these tools, engineers can create more innovative, high-performance products that push the boundaries of what’s possible in the world of electronics.

No responses yet