What is PCB Quality?

PCB (Printed Circuit Board) quality refers to the overall performance, reliability, and durability of a PCB. It encompasses various aspects, such as the materials used, the manufacturing process, and the adherence to industry standards and specifications. High-quality PCBs are essential for ensuring the proper functioning and longevity of electronic devices.

Factors Affecting PCB Quality

Several factors contribute to the quality of a PCB:

- Material selection

- Manufacturing process

- Design and layout

- Testing and inspection

- Compliance with industry standards

PCB Materials and Their Impact on Quality

The choice of materials used in PCB fabrication plays a crucial role in determining the quality of the final product.

Substrate Materials

The substrate is the base material on which the conductive traces and components are placed. Common substrate materials include:

- FR-4: A glass-reinforced epoxy laminate, widely used for its good electrical insulation properties and mechanical strength.

- Polyimide: A high-performance polymer offering excellent thermal stability and flexibility, suitable for flexible PCBs.

- Ceramic: Used in high-frequency and high-temperature applications due to its low dielectric loss and high thermal conductivity.

Copper Foil

Copper foil is used to create the conductive traces on the PCB. The quality of the copper foil affects the electrical performance and reliability of the PCB. Factors to consider include:

- Thickness: Thicker copper foil provides better current-carrying capacity and heat dissipation but may increase manufacturing costs.

- Surface finish: The surface finish protects the copper from oxidation and enhances solderability. Common finishes include HASL (Hot Air Solder Leveling), ENIG (Electroless Nickel Immersion Gold), and OSP (Organic Solderability Preservative).

Solder Mask and Silkscreen

- Solder mask: A protective coating applied over the copper traces to prevent shorts and improve insulation. The quality of the solder mask affects the PCB’s resistance to moisture, chemicals, and mechanical stress.

- Silkscreen: Used to print component designators, logos, and other markings on the PCB. A clear and durable silkscreen improves the readability and aesthetics of the PCB.

PCB Manufacturing Process and Quality Control

The manufacturing process plays a vital role in ensuring PCB quality. Key stages in the PCB manufacturing process include:

- PCB design and layout

- PCB fabrication

- PCB assembly

- Testing and inspection

PCB Design and Layout

A well-designed PCB layout is essential for achieving high quality. Factors to consider include:

- Component placement: Proper component placement ensures optimal signal integrity, reduces electromagnetic interference (EMI), and facilitates efficient assembly.

- Trace routing: Appropriate trace width, spacing, and impedance matching minimize signal distortion and crosstalk.

- Grounding and shielding: Effective grounding and shielding techniques reduce noise and improve signal quality.

PCB Fabrication

The PCB fabrication process involves several steps, each of which can impact the quality of the final product:

- Cleaning and etching: Copper-clad laminates are cleaned and etched to remove unwanted copper, creating the desired conductive patterns.

- Drilling: Holes are drilled through the PCB to accommodate through-hole components and vias.

- Plating: Copper is plated onto the drilled holes and exposed traces to ensure proper electrical connectivity.

- Solder mask application: A solder mask is applied to protect the copper traces and prevent shorts.

- Silkscreen printing: Component designators, logos, and other markings are printed on the PCB using silkscreen.

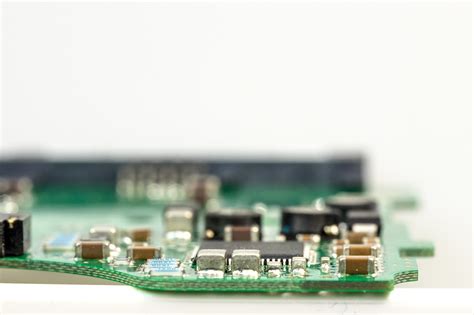

PCB Assembly

The PCB assembly process involves soldering components onto the fabricated PCB. Quality control measures during assembly include:

- Solder paste inspection (SPI): Ensures the correct amount and placement of solder paste on the PCB pads.

- Automated optical inspection (AOI): Detects component placement errors, solder defects, and other assembly issues.

- X-ray inspection: Identifies hidden solder defects, such as voids or shorts, in ball grid array (BGA) and other high-density packages.

Testing and Inspection

Thorough testing and inspection are crucial for ensuring PCB quality. Common testing methods include:

- In-circuit testing (ICT): Verifies the proper connection and functionality of individual components on the PCB.

- Functional testing: Evaluates the overall performance of the assembled PCB under various operating conditions.

- Boundary scan testing: Tests the interconnections between integrated circuits (ICs) on the PCB using a standardized test access port (TAP).

Industry Standards and Certifications

Adherence to industry standards and certifications ensures that PCBs meet established quality requirements. Some key standards and certifications include:

- IPC (Association Connecting Electronics Industries) standards:

- IPC-A-600: Acceptability of Printed Boards

- IPC-A-610: Acceptability of Electronic Assemblies

-

IPC-6012: Qualification and Performance Specification for Rigid Printed Boards

-

ISO (International Organization for Standardization) standards:

- ISO 9001: Quality Management Systems

-

ISO 14001: Environmental Management Systems

-

UL (Underwriters Laboratories) certification:

- UL 94: Standard for Safety of Flammability of Plastic Materials

- UL 796: Standard for Safety of Printed-Wiring Boards

| Standard/Certification | Description |

|---|---|

| IPC-A-600 | Acceptability of Printed Boards |

| IPC-A-610 | Acceptability of Electronic Assemblies |

| IPC-6012 | Qualification and Performance Specification for Rigid Printed Boards |

| ISO 9001 | Quality Management Systems |

| ISO 14001 | Environmental Management Systems |

| UL 94 | Standard for Safety of Flammability of Plastic Materials |

| UL 796 | Standard for Safety of Printed-Wiring Boards |

Choosing a High-Quality PCB Manufacturer

Selecting a reputable PCB manufacturer is crucial for ensuring the quality of your PCBs. When choosing a PCB manufacturer, consider the following factors:

- Experience and expertise: Look for a manufacturer with a proven track record in producing high-quality PCBs for various applications.

- Quality control processes: Ensure that the manufacturer employs strict quality control measures throughout the manufacturing process.

- Certifications and compliance: Choose a manufacturer that adheres to relevant industry standards and holds necessary certifications.

- Technical support: A reliable manufacturer should provide comprehensive technical support to address any issues or concerns.

- Lead time and pricing: Consider the manufacturer’s lead times and pricing structure to ensure they align with your project requirements and budget.

Common PCB Quality Issues and How to Prevent Them

Several common quality issues can arise during PCB manufacturing and assembly. By understanding these issues and implementing preventive measures, you can minimize their occurrence and ensure the production of high-quality PCBs.

Copper Thickness Variation

Copper thickness variation occurs when the copper plating on the PCB is not uniform, leading to inconsistent electrical performance and potential reliability issues. To prevent this issue:

- Specify the appropriate copper thickness for your application

- Use a reputable PCB manufacturer with strict process controls

- Perform regular thickness measurements during fabrication

Solder Defects

Solder defects, such as bridging, voids, and insufficient solder, can cause short circuits, open connections, and poor mechanical strength. To minimize solder defects:

- Use a solder paste with the appropriate composition and viscosity

- Optimize the solder paste printing process

- Implement solder paste inspection (SPI) and automated optical inspection (AOI) during assembly

Delamination

Delamination occurs when the layers of the PCB separate due to poor bonding or excessive stress. To prevent delamination:

- Use high-quality substrate materials with proper glass transition temperature (Tg)

- Control the PCB fabrication process parameters, such as lamination temperature and pressure

- Avoid excessive mechanical stress during handling and assembly

Misaligned or Missing Components

Misaligned or missing components can lead to functional failures and rework costs. To prevent these issues:

- Use a pick-and-place machine with high accuracy and repeatability

- Implement vision systems for component alignment verification

- Perform regular maintenance and calibration of the assembly equipment

Trace Damage or Discontinuity

Trace damage or discontinuity can occur due to manufacturing defects, such as over-etching or mechanical stress. To minimize trace issues:

- Use a PCB design with appropriate trace width and spacing

- Specify the correct etching parameters and control the etching process

- Handle PCBs with care during fabrication and assembly

Frequently Asked Questions (FAQ)

- What is the difference between PCB quality and reliability?

-

PCB quality refers to the overall performance and adherence to specifications at the time of manufacturing, while PCB reliability refers to the ability of the PCB to maintain its quality and function over an extended period under specified operating conditions.

-

How can I ensure the quality of the PCBs I purchase?

-

To ensure the quality of your PCBs, choose a reputable manufacturer with strict quality control processes, specify your requirements clearly, and request test reports and certificates of conformance.

-

What are the most critical factors affecting PCB quality?

-

The most critical factors affecting PCB quality include the choice of materials, the design and layout, the manufacturing process control, and the adherence to industry standards and specifications.

-

How often should I perform quality inspections on my PCBs?

-

The frequency of quality inspections depends on factors such as the complexity of the PCB, the production volume, and the criticality of the application. Typically, inspections should be performed at various stages of the manufacturing process, as well as on a sample basis for incoming PCBs.

-

Can PCB quality issues be repaired, or do I need to scrap the affected boards?

- The feasibility of repairing PCB quality issues depends on the nature and extent of the defect. Some issues, such as minor solder defects or component misalignments, can be reworked, while others, such as severe delamination or trace damage, may require scrapping the affected boards.

Conclusion

PCB quality is a critical factor in ensuring the reliability and performance of electronic devices. By understanding the various aspects that contribute to PCB quality, such as material selection, manufacturing process control, and adherence to industry standards, you can make informed decisions when designing, manufacturing, and sourcing PCBs.

Choosing a reputable PCB manufacturer, implementing strict quality control measures, and performing regular inspections and tests are essential for maintaining high PCB quality. By addressing common quality issues and implementing preventive measures, you can minimize the occurrence of defects and ensure the production of reliable, high-performance PCBs.

Investing in PCB quality ultimately leads to improved product reliability, reduced rework and scrap costs, and enhanced customer satisfaction. As the electronics industry continues to evolve, staying informed about PCB quality best practices and emerging technologies will be crucial for success in an increasingly competitive market.

No responses yet