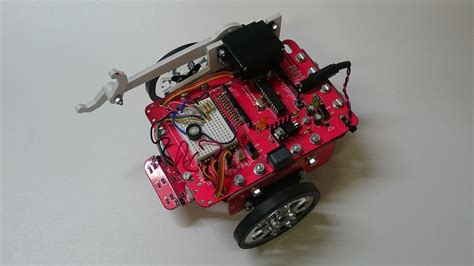

Introduction to PCB Motor Robots

PCB (printed circuit board) motor robots are a fascinating area of robotics that combine electronics, mechanics, and programming to create small, agile robotic devices. By leveraging the power of motors mounted directly onto custom PCBs, these robots can achieve impressive capabilities in a compact form factor.

One of the pioneers and leading innovators in the field of PCB motor robotics is Carl Bugeja, a maker and educator based in Malta. Through his YouTube channel, workshops, and online resources, Bugeja has inspired and educated thousands of people around the world about the potential of PCB motor robots.

In this article, we’ll dive deep into the world of PCB motor robots, exploring their components, design considerations, programming, applications, and the groundbreaking work of Carl Bugeja. By the end, you’ll have a solid understanding of these amazing devices and hopefully be inspired to create your own PCB motor robots.

Key Components of PCB Motor Robots

At the heart of any PCB motor robot are several key components:

Motors

The motors provide the motion and power for the robot. Typically, brushed DC motors or micro gearmotors are used. These motors are mounted directly onto the PCB, either through soldering or with the help of small PCB-mounted gearboxes. The choice of motor depends on the desired speed, torque, and size of the robot.

Motor Drivers

To control the speed and direction of the motors, a motor driver circuit is required. Common options include the L293D dual H-bridge motor driver IC or more advanced options like the TB6612FNG or DRV8833. These drivers allow microcontrollers to send PWM signals to control motor speed and direction.

Microcontrollers

A microcontroller is the brain of the PCB motor robot, running the program that controls the robot’s behavior. Popular choices include Arduino boards (like the Nano or Pro Mini), ESP8266/ESP32 boards, or ATtiny microcontrollers for more compact designs.

Sensors

To help the robot interact with its environment, various sensors can be added. Common options include infrared line sensors for line following, ultrasonic distance sensors for collision avoidance, light sensors, and accelerometers/gyroscopes for detecting motion and orientation.

Batteries

PCB motor robots need a power source to operate untethered. LiPo batteries are a popular choice due to their high energy density and ability to deliver the current required by motors. The battery is typically connected to the PCB through a JST connector or directly soldered.

Other Components

Depending on the specific design and application, a PCB motor robot may include additional components like buttons, switches, LEDs, buzzers, wireless communication modules (Bluetooth, WiFi, radio), or even small OLED displays.

By carefully selecting and integrating these components onto a custom PCB, a compact and capable robot can be created.

PCB Design Considerations for Motor Robots

Designing a custom PCB for a motor robot involves several key considerations to ensure optimal performance, reliability, and ease of assembly.

Motor Placement and Mounting

The placement and mounting of the motors is crucial for a well-functioning robot. Motors should be positioned to provide balanced weight distribution and aligned with the desired direction of motion. They can be soldered directly to the PCB or mounted using small PCB-mounted gearboxes for increased torque. It’s important to consider the motor dimensions, shaft size, and any required mounting holes when designing the PCB.

Battery and Power Management

The battery and power management system must be carefully designed to provide stable and sufficient power to the motors, microcontroller, and other components. This includes selecting an appropriate battery (typically LiPo), including necessary protection circuitry (like over-discharge protection), and designing a robust power distribution network on the PCB. The battery connector should be easily accessible for charging and replacing the battery.

Component Placement and Routing

The placement of components on the PCB should be optimized for compactness, weight distribution, and ease of assembly. It’s important to consider the size and orientation of each component, as well as their interconnections. Routing traces on the PCB should be done in a way that minimizes interference and ensures reliable connections.

Sensor Integration

If the robot includes sensors, their placement and integration onto the PCB must be carefully considered. Sensors should be positioned to provide optimal functionality (e.g., line sensors near the bottom of the PCB) and routed to the microcontroller with minimal interference. Some sensors may require additional circuitry, like pull-up resistors or filtering capacitors.

Mechanical Considerations

The PCB design must also take into account mechanical considerations, such as the overall size and shape of the robot, mounting holes for motors and other components, and any additional mechanical structures (like chassis or wheels) that will interface with the PCB. It’s important to consider the clearance required for components, connectors, and wires to ensure a robust and reliable design.

Manufacturing and Assembly

When designing the PCB, it’s crucial to consider the manufacturing and assembly process. This includes selecting appropriate PCB materials, specifying the correct layer stackup and thickness, and including fiducial markers and other features to aid in assembly. The design should also consider the assembly process, such as the order in which components will be soldered and any required programming or testing steps.

By carefully considering these design aspects, a PCB motor robot can be created that is compact, reliable, and easy to assemble and operate.

Programming PCB Motor Robots

Once the hardware design is complete, the next step is programming the robot’s behavior. The specific programming approach depends on the chosen microcontroller and the desired functionality of the robot.

Arduino Programming

If using an Arduino-compatible board (like the Nano or Pro Mini), programming can be done using the Arduino IDE and the familiar Arduino programming language (based on C++). The Arduino ecosystem provides a wide range of libraries for interfacing with motors, sensors, and other components, making it relatively easy to get started.

Key steps in Arduino programming for PCB motor robots include:

- Setting up the development environment (Arduino IDE)

- Configuring motor control pins and initializing motor objects

- Reading sensor inputs and processing the data

- Implementing control algorithms (e.g., line following, obstacle avoidance)

- Sending appropriate control signals to the motor drivers

- Integrating additional functionality as needed (e.g., wireless communication, display output)

Other Programming Options

For more advanced users or specific requirements, other programming options are available. For example, if using an ESP8266 or ESP32 board, programming can be done using the Arduino IDE with the appropriate board package installed, or using other development frameworks like Espruino (JavaScript) or MicroPython.

In some cases, lower-level programming may be required, such as when using ATtiny microcontrollers or other bare-metal configurations. This involves writing code in C or assembly language and using a programmer (like the AVR ISP) to flash the code onto the microcontroller.

Regardless of the specific programming approach, the key principles remain the same: read sensor inputs, process the data, and send appropriate control signals to the motors and other actuators to achieve the desired behavior.

Designing PCB Motor Robots with Carl Bugeja

One of the leading innovators in the world of PCB motor robots is Carl Bugeja, a Maltese maker and educator who has created numerous groundbreaking designs and shared his knowledge with the global maker community.

Bugeja’s Design Philosophy

Carl Bugeja’s approach to PCB motor robot design is characterized by a focus on simplicity, functionality, and accessibility. His designs often feature a minimalist aesthetic, with the PCB itself serving as the main structural component of the robot. By keeping the design simple and using readily available components, Bugeja makes it easier for others to understand, build, and modify his robots.

At the same time, Bugeja’s robots are highly capable and demonstrate advanced functionality like line following, maze solving, and even sumo wrestling. His designs often incorporate clever mechanical solutions, like using the PCB itself as a chassis or integrating sensors and actuators in unique ways.

Open Source and Knowledge Sharing

A key aspect of Bugeja’s work is his commitment to open source and knowledge sharing. He freely shares the design files, code, and build instructions for his robots, allowing others to learn from and build upon his work. His YouTube channel and website are rich resources of tutorials, project walkthroughs, and insights into the design process.

Community Building and Education

Beyond just sharing his designs, Carl Bugeja is actively involved in building and supporting a global community of PCB robot enthusiasts. He regularly participates in online forums, answers questions, and provides guidance to those looking to get started with PCB robotics.

Additionally, Bugeja is involved in educational outreach, conducting workshops and talks to introduce students and others to the world of PCB motor robots. By making robotics accessible and engaging, he inspires the next generation of makers and engineers.

Through his innovative designs, open source philosophy, and community building efforts, Carl Bugeja has made significant contributions to the advancement and popularization of PCB motor robots.

PCB Motor Robot Applications

PCB motor robots find applications in a wide range of areas, from hobbyist projects to research and education. Some common applications include:

Education and STEM Outreach

PCB motor robots are an excellent tool for teaching principles of electronics, programming, and robotics. Their small size, low cost, and ease of assembly make them well-suited for classroom and workshop settings. Students can learn by building and programming their own robots, gaining hands-on experience with key concepts.

Research and Experimentation

In research settings, PCB motor robots serve as versatile platforms for investigating topics like swarm robotics, multi-agent systems, and novel control algorithms. Their simplicity and modularity allow researchers to quickly prototype and test new ideas.

Hobbyist Projects and Competitions

For hobbyists, PCB motor robots offer endless possibilities for creative projects and friendly competition. From line following and maze solving to mini-sumo wrestling and freestyle robot dance, these small bots can be customized and programmed for a wide range of fun and challenging tasks.

Robotics Skills Training

Building and programming PCB motor robots helps develop key skills that are transferable to larger scale robotics projects and even professional robotics careers. These skills include PCB design, component selection, soldering, programming, and troubleshooting.

Prototyping and Product Development

PCB motor robots can serve as a starting point for developing new robotic products and applications. By quickly iterating on designs and testing functionality at a small scale, designers and engineers can refine their ideas before moving on to larger and more complex prototypes.

As the tools and techniques for PCB motor robot design continue to evolve, it’s likely that we’ll see even more innovative applications emerge, further demonstrating the potential of these compact and capable devices.

Frequently Asked Questions (FAQ)

1. What is a PCB motor robot?

A PCB motor robot is a small robotic device built around a custom printed circuit board (PCB) that integrates the main components, including motors, a microcontroller, sensors, and a battery. The PCB serves as both the electrical circuit and the structural chassis of the robot.

2. What are the advantages of PCB motor robots compared to traditional robots?

PCB motor robots offer several advantages, including:

– Compact size and light weight

– Low cost and easy availability of components

– Simplified assembly and wiring

– Customizable design for specific applications

– Suitability for mass production

3. What skills are needed to build a PCB motor robot?

Building a PCB motor robot involves a combination of skills, including:

– PCB design (using tools like Eagle or KiCad)

– Electronics knowledge (component selection, circuit design)

– Soldering and assembly

– Programming (Arduino, C++, etc.)

– Mechanical design and integration

4. How can I get started with building PCB motor robots?

To get started with PCB motor robots, you can:

– Follow online tutorials and project guides (like those provided by Carl Bugeja)

– Start with a simple kit or pre-designed robot to gain familiarity

– Join online communities and forums to learn from others and get support

– Attend workshops or classes on PCB design and robotics

– Experiment with your own designs and iterations

5. What are some common challenges in building PCB motor robots?

Some common challenges in building PCB motor robots include:

– Designing a PCB that is compact, robust, and easy to assemble

– Selecting appropriate components for the desired functionality and budget

– Ensuring proper power management and battery life

– Debugging and troubleshooting issues with motors, sensors, or code

– Integrating mechanical elements (like wheels or chassis) with the PCB design

With practice, patience, and persistence, these challenges can be overcome, leading to successful and rewarding PCB motor robot projects.

Conclusion

PCB motor robots represent an exciting and accessible area of robotics, offering endless possibilities for learning, creativity, and innovation. Through the efforts of pioneers like Carl Bugeja, these small but capable devices are becoming increasingly popular among makers, educators, and researchers around the world.

By combining electronics, programming, and mechanical design in a compact and customizable package, PCB motor robots provide a platform for exploring a wide range of robotic applications and ideas. Whether you’re a student learning the basics of robotics, a hobbyist looking for a new challenge, or a researcher investigating novel control systems, PCB motor robots offer a powerful and versatile tool.

As the community of PCB motor robot enthusiasts continues to grow and evolve, we can expect to see even more innovative designs, applications, and resources emerge. With the power of open source knowledge sharing and collaboration, the potential for these small robots to make a big impact is truly limitless.

So why not dive in and start exploring the world of PCB motor robots today? With a bit of curiosity, creativity, and perseverance, you too can join the ranks of makers like Carl Bugeja and contribute to the exciting future of this fascinating field.

No responses yet