What are PCBs?

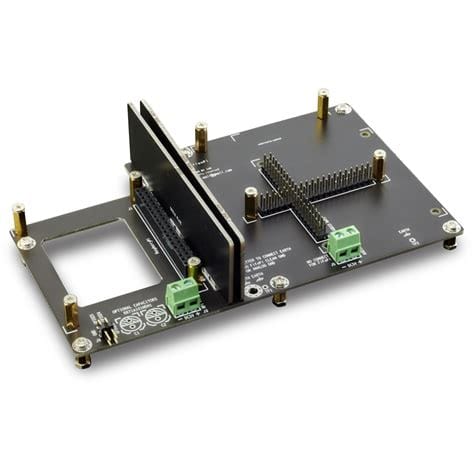

PCBs are the backbone of modern electronics, providing a platform for components to be mounted and connected. They are essentially a thin board made of insulating material, such as fiberglass, with conductive tracks etched onto the surface. These tracks are used to connect the various components, such as resistors, capacitors, and integrated circuits, to create a functional electronic device.

PCBs come in a variety of types, each with its own unique characteristics and applications. Some of the most common types of PCBs include:

- Single-sided PCBs: These have conductive tracks on only one side of the board and are typically used for simple, low-cost applications.

- Double-sided PCBs: These have conductive tracks on both sides of the board, allowing for more complex circuits and higher component density.

- Multi-layer PCBs: These consist of multiple layers of conductive tracks separated by insulating material, allowing for even greater complexity and density.

- Flexible PCBs: These are made from flexible materials, such as polyimide, and can be bent or folded to fit into tight spaces or conform to unusual shapes.

- Rigid-flex PCBs: These combine the benefits of both rigid and flexible PCBs, with rigid sections for mounting components and flexible sections for connecting them.

The PCB Manufacturing Process

The PCB manufacturing process typically involves several steps, each of which requires specialized equipment and expertise. The basic steps in the process include:

-

Design: The first step is to create a detailed design of the PCB using computer-aided design (CAD) software. This design includes the placement of components, the routing of conductive tracks, and any other features required for the specific application.

-

Printing: Once the design is complete, it is printed onto a special film called a photomask. This film is used to transfer the design onto the PCB substrate in the next step.

-

Etching: The PCB substrate, which is typically made of fiberglass or other insulating material, is coated with a layer of copper. The photomask is then placed on top of the copper layer and exposed to light, which hardens the areas of the copper that will remain on the board. The unhardened copper is then removed using a chemical etching process, leaving only the desired conductive tracks.

-

Drilling: Holes are drilled into the PCB to allow for the mounting of components and the connection of layers in multi-layer boards.

-

Plating: The holes and conductive tracks are then plated with a thin layer of copper to improve conductivity and durability.

-

Solder mask application: A layer of solder mask is applied to the PCB to protect the conductive tracks and prevent short circuits.

-

Silkscreen printing: Text and symbols are printed onto the PCB using a silkscreen process to aid in assembly and identification of components.

-

Surface finishing: The PCB is then finished with a protective coating, such as gold or silver, to improve durability and prevent oxidation.

-

Testing: Finally, the PCB is tested to ensure that it meets all relevant quality standards and functions as intended.

Leading PCB Manufacturers in Canada

Canada is home to a number of leading PCB manufacturers, each with its own unique capabilities and areas of expertise. Some of the top PCB manufacturers in Canada include:

1. Candor Industries

Candor Industries is a full-service PCB manufacturer based in Toronto, Ontario. The company offers a wide range of PCB services, including design, prototyping, and production, and specializes in high-density interconnect (HDI) and rigid-flex PCBs. Candor Industries serves a variety of industries, including aerospace, defense, medical, and telecommunications.

2. Alberta Printed Circuits

Alberta Printed Circuits is a PCB manufacturer based in Calgary, Alberta. The company offers a range of PCB services, including design, prototyping, and production, and specializes in quick-turn prototyping and low-volume production runs. Alberta Printed Circuits serves a variety of industries, including oil and gas, aerospace, and medical.

3. Cirrascale PCB

Cirrascale PCB is a PCB manufacturer based in Vancouver, British Columbia. The company offers a range of PCB services, including design, prototyping, and production, and specializes in high-density interconnect (HDI) and rigid-flex PCBs. Cirrascale PCB serves a variety of industries, including aerospace, defense, and telecommunications.

4. Enigma Interconnect

Enigma Interconnect is a PCB manufacturer based in Burnaby, British Columbia. The company offers a range of PCB services, including design, prototyping, and production, and specializes in quick-turn prototyping and high-volume production runs. Enigma Interconnect serves a variety of industries, including consumer electronics, automotive, and medical.

5. SFM Technology

SFM Technology is a PCB manufacturer based in Markham, Ontario. The company offers a range of PCB services, including design, prototyping, and production, and specializes in high-density interconnect (HDI) and rigid-flex PCBs. SFM Technology serves a variety of industries, including aerospace, defense, and medical.

| Company Name | Location | Specialties | Industries Served |

|---|---|---|---|

| Candor Industries | Toronto, ON | HDI, rigid-flex PCBs | Aerospace, defense, medical, telecommunications |

| Alberta Printed Circuits | Calgary, AB | Quick-turn prototyping, low-volume production | Oil and gas, aerospace, medical |

| Cirrascale PCB | Vancouver, BC | HDI, rigid-flex PCBs | Aerospace, defense, telecommunications |

| Enigma Interconnect | Burnaby, BC | Quick-turn prototyping, high-volume production | Consumer electronics, automotive, medical |

| SFM Technology | Markham, ON | HDI, rigid-flex PCBs | Aerospace, defense, medical |

Choosing a PCB Manufacturer in Canada

When choosing a PCB manufacturer in Canada, there are several factors to consider to ensure that you find the right partner for your project. Some of the key factors to consider include:

Technical Capabilities

Different PCB manufacturers have different technical capabilities, so it’s important to choose a manufacturer that has experience with the specific type of PCB you need. For example, if you need a high-density interconnect (HDI) PCB, you’ll want to choose a manufacturer that specializes in this type of PCB.

Quality Control

Quality control is critical in PCB manufacturing, as even small defects can lead to failures in the final product. When choosing a PCB manufacturer, look for one that has robust quality control processes in place, including testing at various stages of the manufacturing process.

Turnaround Time

Depending on your project timeline, turnaround time may be a critical factor in choosing a PCB manufacturer. Some manufacturers specialize in quick-turn prototyping, while others may be better suited for high-volume production runs. Be sure to discuss your timeline with potential manufacturers to ensure that they can meet your needs.

Cost

Cost is always a factor in any manufacturing project, and PCBs are no exception. When comparing PCB manufacturers, be sure to get detailed quotes that include all costs associated with your project, including design, materials, and shipping.

Customer Service

Finally, customer service is an important consideration when choosing a PCB manufacturer. Look for a manufacturer that is responsive to your needs and willing to work with you to ensure that your project is a success. A good manufacturer will be available to answer your questions and provide support throughout the manufacturing process.

Frequently Asked Questions (FAQ)

- What is the minimum order quantity for PCBs in Canada?

-

The minimum order quantity for PCBs in Canada varies by manufacturer, but many offer low minimum order quantities for prototyping and small production runs. Some manufacturers may have minimum order quantities as low as one or two boards, while others may require a minimum order of 100 or more.

-

How long does it take to manufacture a PCB in Canada?

-

The turnaround time for PCB manufacturing in Canada varies depending on the complexity of the board and the manufacturer’s workload. For simple prototypes, some manufacturers may be able to deliver boards in as little as 24 hours, while more complex boards may take several weeks to manufacture.

-

What is the typical cost of a PCB in Canada?

-

The cost of a PCB in Canada depends on a variety of factors, including the size and complexity of the board, the materials used, and the quantity ordered. As a rough estimate, a simple double-sided PCB may cost around $10-20 per board for a small quantity, while more complex boards can cost several hundred dollars each.

-

What certifications do Canadian PCB manufacturers typically hold?

-

Canadian PCB manufacturers may hold a variety of certifications, depending on their specific areas of expertise and the industries they serve. Some common certifications include ISO 9001 for quality management, ISO 14001 for environmental management, and IATF 16949 for automotive quality management.

-

Can Canadian PCB manufacturers help with PCB Design?

- Yes, many Canadian PCB manufacturers offer PCB design services in addition to manufacturing. These services can include schematic capture, PCB layout, and design for manufacturing (DFM) analysis. Some manufacturers may also offer assistance with component selection and supply chain management.

Conclusion

PCB manufacturing is a critical industry in Canada, with numerous companies offering a wide range of services to meet the needs of businesses and individuals alike. From simple single-sided boards to complex multi-layer and Rigid-Flex Designs, Canadian PCB manufacturers have the expertise and capabilities to bring your electronic projects to life.

When choosing a PCB manufacturer in Canada, it’s important to consider factors such as technical capabilities, quality control, turnaround time, cost, and customer service. By taking the time to research and compare potential manufacturers, you can find the right partner to help bring your PCB project from concept to reality.

No responses yet