What is a PCB Holder and Why Do You Need One?

A PCB holder is an essential tool for anyone who frequently works with printed circuit boards (PCBs). It is a device that securely holds a PCB in place while you solder components onto it, making the soldering process much easier and more precise.

Soldering small components onto a PCB can be a challenging task, especially if you are trying to hold the board with one hand while soldering with the other. A PCB holder eliminates this problem by firmly gripping the board, allowing you to use both hands for soldering.

Using a PCB holder has several advantages:

- It keeps the PCB stable and prevents it from moving while you work on it.

- It frees up both of your hands, allowing you to solder with greater precision and control.

- It reduces the risk of accidentally touching or burning yourself with the soldering iron.

- It helps to prevent damage to the PCB or components caused by accidental drops or mishandling.

Types of PCB Holders

There are several different types of PCB holders available on the market, each with its own unique features and benefits.

Third Hand PCB Holder

The Third Hand PCB holder is one of the most popular types of holders used by hobbyists and DIY enthusiasts. It consists of a heavy base with adjustable metal arms that can be positioned to hold the PCB at various angles. Some Third Hand holders also include a magnifying glass or light to help you see small components more clearly.

| Pros | Cons |

|---|---|

| Inexpensive | May not be sturdy enough for larger PCBs |

| Adjustable arms for flexible positioning | Arms may not hold PCB securely |

| Portable and easy to store | Magnifying glass/light quality may be poor |

Self-Centering PCB Holder

A self-centering PCB holder is a more advanced type of holder that automatically centers the PCB and holds it securely in place. These holders typically have a lever or knob that you turn to adjust the clamping mechanism and ensure a tight grip on the board.

| Pros | Cons |

|---|---|

| Automatically centers PCB for precise positioning | More expensive than basic holders |

| Securely holds PCB in place | May not be compatible with all PCB sizes/shapes |

| Easy to use with one-handed operation | Can be bulky and take up more workspace |

Magnetic PCB Holder

Magnetic PCB holders use strong magnets to hold the PCB in place on a metal base. These holders are popular among professionals because they offer a strong, reliable grip and can accommodate PCBs of various sizes.

| Pros | Cons |

|---|---|

| Strong magnetic grip holds PCB securely | Requires PCB to have metal backing for magnet to work |

| Can accommodate various PCB sizes | May not work well with very small or oddly shaped PCBs |

| Durable and long-lasting | More expensive than other types of holders |

How to Choose the Right PCB Holder

When choosing a PCB holder, there are several factors to consider:

- Size and shape of your PCBs: Make sure the holder you choose can accommodate the size and shape of the PCBs you typically work with.

- Sturdiness and durability: Look for a holder with a sturdy base and high-quality materials that will hold up over time.

- Adjustability: Consider whether you need a holder with adjustable arms or clamps to accommodate different PCB positions and angles.

- Ease of use: Choose a holder that is easy to operate with one hand, so you can keep your other hand free for soldering.

- Price: Determine your budget and look for a holder that offers the best value for your money.

Tips for Using a PCB Holder

Once you have chosen a PCB holder, here are some tips for using it effectively:

- Clean your PCB: Before placing your PCB in the holder, make sure it is clean and free of debris that could interfere with soldering.

- Adjust the holder for optimal positioning: Take a moment to adjust the arms or clamps of your holder so that the PCB is held securely and at a comfortable angle for soldering.

- Use appropriate soldering techniques: A PCB holder can make soldering easier, but it’s still important to use proper soldering techniques to ensure a strong, reliable connection.

- Keep your workspace organized: A cluttered workspace can make it difficult to use your PCB holder effectively. Keep your tools and components organized and within easy reach.

- Practice safety: Always wear protective eyewear and use caution when working with hot soldering irons to prevent injury.

Frequently Asked Questions (FAQ) About PCB Holders

1. Can I use a PCB holder for SMD soldering?

Yes, PCB holders can be used for both through-hole and surface-mount (SMD) soldering. Some holders even have special features like pivoting heads or fine-adjustment knobs that make SMD soldering easier.

2. How do I know what size PCB holder to get?

When choosing a PCB holder, consider the size and shape of the PCBs you typically work with. Some holders are adjustable and can accommodate a range of PCB sizes, while others are designed for specific dimensions.

3. Are PCB holders expensive?

The cost of a PCB holder can vary depending on the type, brand, and features. Basic Third Hand holders can be very affordable, while more advanced self-centering or magnetic holders may be more expensive. Consider your budget and soldering needs when choosing a holder.

4. Do I really need a PCB holder?

While a PCB holder is not strictly necessary for soldering, it can make the process much easier, faster, and more precise. If you frequently work with PCBs or are new to soldering, a PCB holder can be a worthwhile investment.

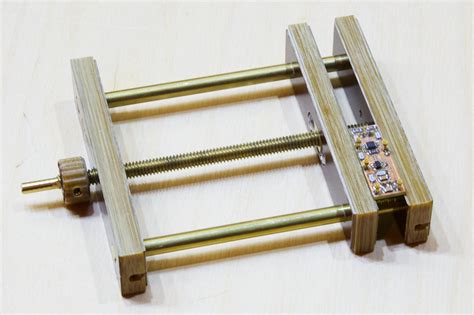

5. Can I make my own PCB holder?

Yes, it is possible to make your own PCB holder using materials like wood, metal, or 3D-printed plastic. There are many DIY PCB holder designs available online, ranging from simple to complex. However, making your own holder may not be as cost-effective or reliable as purchasing a professionally made one.

Conclusion

A PCB holder is a valuable tool for anyone who works with printed circuit boards, whether you are a hobbyist or a professional. By securely holding the PCB in place, a holder allows you to solder with greater precision, speed, and safety.

When choosing a PCB holder, consider factors like the size and shape of your PCBs, the sturdiness and adjustability of the holder, and your budget. With the right holder and proper soldering techniques, you can take your PCB projects to the next level.

No responses yet