Introduction to PCB Gerber Viewers

PCB (Printed Circuit Board) design is a complex process that involves multiple steps, from schematic capture to PCB layout and manufacturing. One crucial aspect of the PCB design process is the generation and verification of Gerber files. Gerber files are the standard format used by PCB manufacturers to fabricate the physical boards. To ensure that the manufactured PCBs match the designed layout, it is essential to use a reliable PCB Gerber viewer.

A PCB Gerber viewer is a software tool that allows designers and engineers to visualize and inspect Gerber files before sending them for manufacturing. It provides a graphical representation of the PCB layout, enabling users to identify any potential issues or errors in the design. By using a PCB Gerber viewer, designers can catch and rectify problems early in the process, saving time and reducing the risk of costly manufacturing mistakes.

Key Features of PCB Gerber Viewers

-

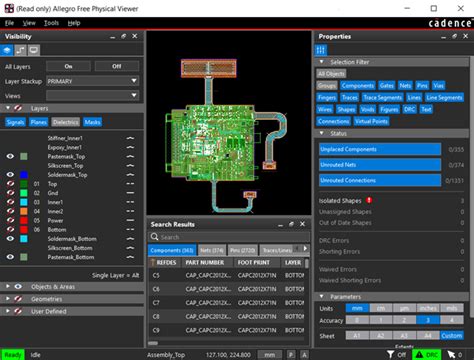

Visual Inspection: PCB Gerber viewers provide a clear and detailed visual representation of the PCB layout, allowing designers to inspect the various layers, traces, and components.

-

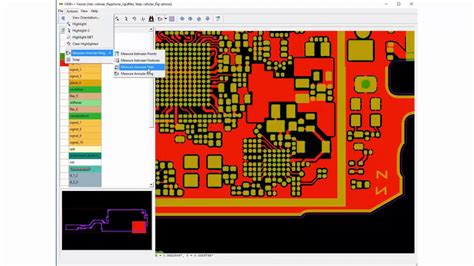

Layer Management: Gerber viewers enable users to selectively view or hide specific layers, making it easier to focus on specific aspects of the design.

-

Measurement Tools: Most Gerber viewers include measurement tools that allow designers to verify dimensions, distances, and clearances within the PCB layout.

-

Design Rule Checking (DRC): Some advanced PCB Gerber viewers offer built-in DRC capabilities, automatically checking the design for potential manufacturing issues or violations of design rules.

-

Collaboration and Sharing: Many Gerber viewers support collaboration features, allowing team members to share and review designs together, facilitating effective communication and feedback.

Importance of Using a PCB Gerber Viewer

Catching Design Errors Early

One of the primary reasons for using a PCB Gerber viewer is to identify and rectify design errors before sending the files for manufacturing. By visually inspecting the Gerber files, designers can spot issues such as incorrect trace widths, missing or overlapping components, or violations of design rules. Catching these errors early in the process can save significant time and cost associated with manufacturing defective boards.

Ensuring Manufacturability

PCB Gerber viewers help designers ensure that their designs are manufacturable. By reviewing the Gerber files, designers can verify that the PCB layout meets the manufacturing capabilities and constraints of the chosen fabrication house. This includes checking for minimum trace widths, clearances, drill sizes, and other manufacturing requirements. By ensuring manufacturability upfront, designers can avoid potential delays or rejections during the manufacturing process.

Facilitating Communication with Manufacturers

When working with PCB manufacturers, clear communication is essential. PCB Gerber viewers provide a common language and visual reference for designers and manufacturers to discuss and clarify any aspects of the PCB design. By sharing the Gerber files and using the viewer to highlight specific areas of interest, designers can effectively convey their intentions and requirements to the manufacturing team, reducing the chances of misinterpretation or miscommunication.

Streamlining the PCB Design Workflow

Integrating a PCB Gerber viewer into the design workflow can significantly streamline the process. By regularly reviewing and verifying the Gerber files throughout the design stages, designers can catch and address issues early on, reducing the need for multiple iterations and revisions. This proactive approach helps to optimize the design process, leading to faster turnaround times and improved overall efficiency.

Popular PCB Gerber Viewers

There are several PCB Gerber viewers available in the market, each with its own set of features and capabilities. Some popular options include:

-

Gerbv: Gerbv is a free and open-source PCB Gerber viewer that supports a wide range of Gerber and drill file formats. It offers basic visualization and inspection features, making it a good choice for simple PCB designs.

-

ViewMate: ViewMate is a powerful PCB Gerber viewer developed by Pentalogix. It provides advanced features such as 3D visualization, design rule checking, and automatic layer recognition. ViewMate is available in both free and paid versions, with the paid version offering additional functionality.

-

GC-Prevue: GC-Prevue is a comprehensive PCB Gerber viewer and editor developed by GraphiCode. It offers a wide range of tools for visualizing, analyzing, and modifying Gerber files. GC-Prevue supports advanced features like netlist comparison, copper area calculation, and automatic layer alignment.

-

CAM350: CAM350 is a high-end PCB Gerber viewer and CAM (Computer-Aided Manufacturing) tool developed by DownStream Technologies. It provides a comprehensive set of features for PCB design analysis, manufacturing preparation, and documentation. CAM350 is widely used in professional PCB design environments.

| PCB Gerber Viewer | Key Features | Pricing |

|---|---|---|

| Gerbv | – Free and open-source – Supports various Gerber and drill file formats – Basic visualization and inspection tools |

Free |

| ViewMate | – 3D visualization – Design rule checking – Automatic layer recognition |

Free and paid versions available |

| GC-Prevue | – Comprehensive Gerber viewer and editor – Netlist comparison – Copper area calculation – Automatic layer alignment |

Paid |

| CAM350 | – High-end PCB Gerber viewer and CAM tool – PCB design analysis – Manufacturing preparation – Documentation features |

Paid |

Best Practices for Using a PCB Gerber Viewer

To make the most out of a PCB Gerber viewer and ensure effective design verification, consider the following best practices:

-

Verify Layer Alignment: Check that all layers in the Gerber files are properly aligned and registered. Misaligned layers can lead to manufacturing issues and potential failures.

-

Check for Manufacturability: Review the Gerber files against the manufacturing capabilities and constraints of the chosen fabrication house. Ensure that the design meets the minimum trace widths, clearances, and drill sizes required for successful manufacturing.

-

Perform Design Rule Checks: Utilize the design rule checking (DRC) features provided by the PCB Gerber viewer, if available. DRC helps identify potential design issues, such as short circuits, open circuits, or violations of spacing rules.

-

Inspect Critical Areas: Pay special attention to critical areas of the PCB design, such as power and ground planes, high-speed signals, and sensitive analog circuits. Ensure that these areas are properly designed and free from any errors or anomalies.

-

Collaborate with Team Members: Leverage the collaboration features of the PCB Gerber viewer to share and review designs with team members. Encourage open communication and feedback to catch any issues or improvements early in the process.

-

Generate Comprehensive Documentation: Use the PCB Gerber viewer to generate detailed documentation, including layer stackups, drill reports, and assembly drawings. Clear and comprehensive documentation helps ensure smooth communication with the manufacturing team and reduces the risk of errors.

Frequently Asked Questions (FAQ)

-

What are Gerber files?

Gerber files are the standard file format used in the PCB industry to describe the layout and structure of a printed circuit board. They contain information about the copper layers, solder mask, silkscreen, and drill holes of a PCB design. -

Why is it important to use a PCB Gerber viewer?

Using a PCB Gerber viewer is crucial for verifying the accuracy and manufacturability of PCB designs before sending them for fabrication. It allows designers to visually inspect the Gerber files, catch potential errors, and ensure that the design meets manufacturing requirements, ultimately saving time and reducing the risk of costly mistakes. -

Can PCB Gerber viewers modify Gerber files?

While some advanced PCB Gerber viewers offer editing capabilities, their primary purpose is for visualization and inspection. If modifications to the Gerber files are necessary, it is generally recommended to make those changes in the original PCB design software and then regenerate the Gerber files. -

Are PCB Gerber viewers compatible with all PCB design software?

Most PCB Gerber viewers are compatible with Gerber files generated from various PCB design software packages. However, it’s always a good idea to verify the compatibility of the specific Gerber viewer with the design software being used to ensure smooth file import and visualization. -

How do I choose the right PCB Gerber viewer for my needs?

When selecting a PCB Gerber viewer, consider factors such as the complexity of your PCB designs, the features and tools offered by the viewer, compatibility with your design software, and budget. Evaluate different options, read user reviews, and consider the level of support and updates provided by the software vendor.

Conclusion

PCB Gerber viewers play a vital role in the PCB design and manufacturing process. By providing a visual representation of the Gerber files, these tools enable designers to verify the accuracy and manufacturability of their designs before committing them to fabrication. Using a PCB Gerber viewer helps catch design errors early, ensures compliance with manufacturing requirements, facilitates communication with manufacturers, and streamlines the overall PCB design workflow.

When incorporating a PCB Gerber viewer into your design process, consider the best practices discussed in this article. Verify layer alignment, check for manufacturability, perform design rule checks, inspect critical areas, collaborate with team members, and generate comprehensive documentation. By following these guidelines and leveraging the capabilities of a reliable PCB Gerber viewer, you can enhance the quality and efficiency of your PCB designs, ultimately leading to successful manufacturing outcomes.

As PCB designs continue to evolve in complexity and density, the importance of using a robust PCB Gerber viewer cannot be overstated. Investing in a suitable viewer and integrating it into your design workflow can yield significant benefits in terms of time savings, error reduction, and overall project success. By embracing the power of PCB Gerber viewers, designers can navigate the complexities of PCB design with confidence and deliver high-quality, manufacturable boards that meet the ever-increasing demands of modern electronics.

No responses yet