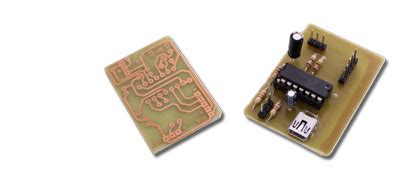

Introduction to Fabtotum PCB

Fabtotum is an all-in-one 3D printer, scanner, and CNC machine that has revolutionized the world of digital fabrication. One of the key components of the Fabtotum is its PCB (Printed Circuit Board) for the wired printing head. In this article, we will dive deep into the details of the Fabtotum PCB, its features, functions, and how it contributes to the overall performance of the machine.

What is a PCB?

Before we delve into the specifics of the Fabtotum PCB, let’s first understand what a PCB is. A PCB is a flat board made of insulating material, such as fiberglass, with conductive tracks printed on its surface. These tracks connect various electronic components, such as resistors, capacitors, and integrated circuits, to form a complete electronic circuit.

PCBs are used in almost all electronic devices, from smartphones and laptops to industrial machinery and medical equipment. They provide a compact and efficient way to connect electronic components and ensure reliable performance.

The Role of PCB in Fabtotum

In the Fabtotum, the PCB plays a crucial role in controlling the wired printing head. The printing head is responsible for extruding the filament material and depositing it layer by layer to create a 3D object. The PCB acts as the brain of the printing head, controlling its movement, temperature, and other parameters.

The Fabtotum PCB is designed to be compact and efficient, allowing it to fit seamlessly into the printing head assembly. It is also designed to be robust and reliable, ensuring consistent performance even under heavy use.

Features of Fabtotum PCB

Microcontroller

At the heart of the Fabtotum PCB is a microcontroller, which is responsible for executing the firmware and controlling the various functions of the printing head. The microcontroller used in the Fabtotum PCB is an Atmel ATmega2560, which is a powerful 8-bit microcontroller with 256KB of flash memory and 8KB of SRAM.

The ATmega2560 is a popular choice for 3D printing applications due to its high performance and low power consumption. It is also compatible with the Arduino development environment, which makes it easy for users to modify and customize the firmware.

Stepper Motor Drivers

The Fabtotum PCB includes stepper motor drivers for controlling the movement of the printing head. Stepper motors are used in 3D printers because they provide precise and accurate motion control, which is essential for creating high-quality prints.

The Fabtotum PCB uses Allegro A4988 stepper motor drivers, which are capable of driving bipolar stepper motors with up to 2A of current per coil. The A4988 drivers also feature adjustable current limiting, over-current protection, and over-temperature shutdown, ensuring safe and reliable operation.

Temperature Sensing

Temperature control is critical in 3D printing, as it affects the quality and consistency of the printed object. The Fabtotum PCB includes a temperature sensing circuit for monitoring the temperature of the printing head and the heated bed.

The temperature sensing circuit uses thermistors, which are temperature-dependent resistors, to measure the temperature of the printing head and heated bed. The thermistor readings are then processed by the microcontroller to maintain the desired temperature setpoint.

Power Management

The Fabtotum PCB includes a power management circuit for regulating the power supply to the various components of the printing head. The power management circuit includes Voltage Regulators, which step down the input voltage to the required levels for the microcontroller, stepper motor drivers, and other components.

The power management circuit also includes protection features, such as over-voltage and over-current protection, to ensure safe and reliable operation.

Connectivity

The Fabtotum PCB includes various connectivity options for communicating with the main control board and other devices. The PCB includes a USB interface for connecting to a computer or other USB host device, allowing users to upload firmware updates and control the printer using software such as Cura or Simplify3D.

The PCB also includes a UART (Universal Asynchronous Receiver/Transmitter) interface for communicating with the main control board. The UART interface allows the PCB to receive commands from the main control board and send back status information, such as temperature readings and motion Feedback.

| Component | Description |

|---|---|

| Microcontroller | Atmel ATmega2560 8-bit microcontroller |

| Stepper Drivers | Allegro A4988 stepper motor drivers |

| Temperature Sensor | Thermistors for measuring printing head and heated bed temp |

| Power Management | Voltage regulators and protection circuits |

| Connectivity | USB interface for firmware updates and UART for control board |

Benefits of Fabtotum PCB

Improved Print Quality

The Fabtotum PCB contributes to improved print quality by providing precise and accurate motion control, temperature regulation, and power management. By ensuring consistent and reliable performance of the printing head, the PCB helps to minimize defects and improve the overall quality of the printed object.

Increased Reliability

The Fabtotum PCB is designed with reliability in mind, featuring robust components and protection circuits to ensure safe and consistent operation. The PCB also undergoes rigorous testing and quality control to ensure that it meets the highest standards of performance and durability.

Customization and Upgradability

The Fabtotum PCB is designed to be customizable and upgradable, allowing users to modify and improve the performance of their printer. The PCB is compatible with the Arduino development environment, which makes it easy for users to modify the firmware and add new features and functionality.

Users can also upgrade the PCB with new components, such as higher-performance stepper motor drivers or more advanced temperature sensors, to further enhance the performance of their printer.

FAQs

Q: Can I replace the Fabtotum PCB with a generic PCB?

A: While it is possible to use a generic PCB in place of the Fabtotum PCB, it is not recommended. The Fabtotum PCB is specifically designed for the Fabtotum printer and includes features and components that are optimized for its performance. Using a generic PCB may result in reduced print quality, reliability, and compatibility issues.

Q: How do I update the firmware on the Fabtotum PCB?

A: To update the firmware on the Fabtotum PCB, you will need to connect the PCB to a computer using the USB interface. You can then use software such as Arduino IDE or Cura to upload the new firmware to the PCB. It is important to follow the manufacturer’s instructions and use the correct firmware version to avoid damaging the PCB or printer.

Q: Can I add new features to the Fabtotum PCB?

A: Yes, the Fabtotum PCB is designed to be customizable and upgradable, allowing users to add new features and functionality. Users can modify the firmware using the Arduino development environment or add new hardware components to the PCB. However, it is important to have a good understanding of electronics and programming before attempting any modifications.

Q: What should I do if the Fabtotum PCB is not working properly?

A: If the Fabtotum PCB is not working properly, the first step is to check the connections and ensure that all components are properly seated and secured. If the issue persists, you may need to troubleshoot the PCB using a multimeter or other diagnostic tools. If you are not comfortable with electronics, it is recommended to seek the assistance of a qualified technician or contact the manufacturer for support.

Q: How long does the Fabtotum PCB last?

A: The lifespan of the Fabtotum PCB depends on various factors, such as usage, environment, and maintenance. With proper care and maintenance, the PCB can last for several years or more. However, like all electronic components, the PCB may eventually wear out or fail due to age, exposure to heat and humidity, or other factors. It is important to follow the manufacturer’s guidelines for maintenance and storage to ensure the longevity of the PCB.

Conclusion

The Fabtotum PCB is a critical component of the Fabtotum 3D printer, responsible for controlling the wired printing head and ensuring consistent and reliable performance. The PCB features a powerful microcontroller, stepper motor drivers, temperature sensing, power management, and connectivity options, all designed to work together seamlessly to produce high-quality prints.

By understanding the features and functions of the Fabtotum PCB, users can better appreciate the capabilities of their printer and troubleshoot any issues that may arise. The customizable and upgradable nature of the PCB also allows users to modify and improve the performance of their printer to suit their specific needs and requirements.

Overall, the Fabtotum PCB is a testament to the innovation and engineering that goes into modern 3D printing technology. As the industry continues to evolve and advance, we can expect to see even more sophisticated and capable PCBs that push the boundaries of what is possible with digital fabrication.

No responses yet