Introduction to PCB-Library

A PCB footprint library is an essential tool for electronic design automation (EDA) software, containing a collection of component footprints used in printed circuit board (PCB) design. These footprints represent the physical dimensions and characteristics of electronic components, enabling designers to create accurate PCB layouts. In this comprehensive guide, we will explore the fundamentals of PCB footprint libraries, their importance in the design process, and best practices for creating and managing them.

What is a PCB Footprint?

A PCB footprint, also known as a land pattern, is a graphical representation of a component’s physical dimensions and connection points on a PCB. It defines the size, shape, and placement of pads, holes, and other features necessary for soldering the component to the board. Footprints are crucial for ensuring proper component fit and assembly.

The Role of PCB-Library in Electronic Design

PCB footprint libraries play a vital role in electronic design by providing a centralized repository of component footprints. They enable designers to quickly select and place components on the PCB layout, saving time and reducing errors. By using standardized footprints, designers can ensure consistency and compatibility across different designs.

Types of PCB Footprints

PCB footprints come in various types, each designed to accommodate specific component packages. Some common footprint types include:

| Footprint Type | Description |

|---|---|

| SMD | Surface Mount Device footprints for components without leads |

| THT | Through-Hole Technology footprints for leaded components |

| BGA | Ball Grid Array footprints for high-density components |

| QFP | Quad Flat Package footprints for integrated circuits |

| DIP | Dual In-line Package footprints for through-hole ICs |

SMD Footprints

Surface Mount Device (SMD) footprints are designed for components that are soldered directly onto the surface of the PCB without through-holes. SMD footprints are compact and enable high-density PCB designs. They typically include pads for each component lead, with specific dimensions and spacing based on the component package.

THT Footprints

Through-Hole Technology (THT) footprints are used for components with leads that are inserted into drilled holes on the PCB and soldered on the opposite side. THT footprints include pad shapes and hole sizes that match the component leads. Although THT components are larger than SMD, they offer stronger mechanical connections and are easier to hand-solder.

BGA footprints

Ball Grid Array (BGA) footprints are designed for high-density components with a grid of solder balls underneath the package. BGA footprints consist of a matrix of circular pads that align with the solder balls. Due to their high pin count and small pitch, BGA footprints require precise alignment and specialized soldering techniques.

QFP Footprints

Quad Flat Package (QFP) footprints are used for integrated circuits with leads extending from all four sides of the package. QFP footprints have elongated pads that match the component lead pitch and provide sufficient space for soldering. They offer a balance between component density and ease of assembly.

DIP Footprints

Dual In-line Package (DIP) footprints are designed for through-hole integrated circuits with two parallel rows of leads. DIP footprints include rectangular pads and holes that accommodate the component leads. They are commonly used for larger ICs and provide good mechanical stability.

Creating PCB Footprints

Creating accurate PCB footprints is essential for successful PCB design and manufacturing. Here are the key steps involved in creating a PCB footprint:

-

Obtain Component Specifications: Gather detailed information about the component, including package dimensions, lead pitch, and any specific requirements from the manufacturer’s datasheet.

-

Choose the Appropriate Footprint Type: Select the footprint type that matches the component package, such as SMD, THT, BGA, QFP, or DIP.

-

Define Pad Dimensions and Spacing: Determine the size and shape of the pads based on the component leads and the desired soldering requirements. Ensure appropriate spacing between pads to prevent short circuits.

-

Add Silkscreen and Assembly Notes: Include silkscreen outlines and text to indicate component orientation, pin numbering, and any assembly notes or guidelines.

-

Verify Footprint Accuracy: Double-check the footprint dimensions against the component datasheet and perform a visual inspection to ensure accuracy.

-

Test and Validate: Create a prototype PCB with the newly created footprint and test it with the actual component to validate the footprint design.

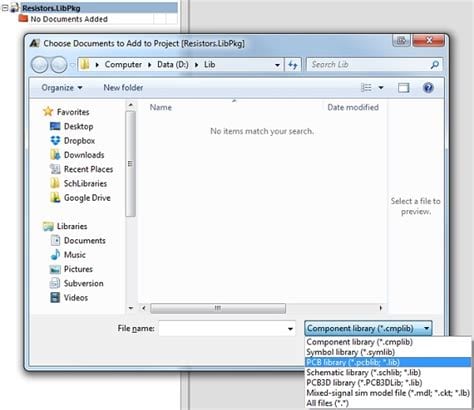

Footprint Creation Tools

Various EDA software packages offer tools for creating PCB footprints. Some popular options include:

- Altium Designer

- KiCad

- Eagle PCB

- OrCAD PCB Editor

These tools provide graphical interfaces and libraries of pre-built footprints to streamline the footprint creation process. They also allow for customization and the ability to import footprints from other sources.

Managing PCB-Library

Effective management of PCB footprint libraries is crucial for maintaining design consistency and efficiency. Here are some best practices for managing PCB-Library:

-

Standardization: Establish standardized naming conventions and footprint parameters to ensure consistency across designs and teams.

-

Version Control: Implement version control systems to track changes and revisions to footprint libraries over time. This allows for easy collaboration and rollback if necessary.

-

Documentation: Maintain clear documentation for each footprint, including creation date, author, and any specific notes or guidelines.

-

Regular Updates: Keep the footprint library up to date with the latest component releases and industry standards. Regularly review and update footprints to incorporate any changes or improvements.

-

Access Control: Implement access control measures to ensure that only authorized individuals can modify the footprint library, reducing the risk of unintended changes or errors.

Footprint Library Resources

There are numerous resources available for obtaining pre-built PCB footprints and expanding your PCB-Library. Some popular resources include:

- Component manufacturer websites

- EDA software vendor libraries

- Online footprint repositories (e.g., SnapEDA, PCB Libraries)

- Open-source hardware projects and communities

These resources provide a wide range of footprints for various components and can save significant time and effort in footprint creation.

Conclusion

PCB footprint libraries are essential tools for efficient and accurate PCB design. By understanding the types of footprints, the creation process, and best practices for library management, designers can streamline their workflows and ensure high-quality PCB layouts. Utilizing pre-built footprints from reliable sources and maintaining a well-organized PCB-Library can greatly enhance productivity and reduce design errors.

Frequently Asked Questions (FAQ)

-

What is the difference between a PCB footprint and a schematic symbol?

A PCB footprint represents the physical dimensions and layout of a component on the PCB, while a schematic symbol represents the electrical properties and connections of the component in the schematic diagram. -

Can I use the same footprint for different components?

Generally, each component requires a specific footprint that matches its package dimensions and lead configuration. Using the wrong footprint can lead to assembly issues and malfunctions. However, some components with similar packages may share the same footprint. -

How do I ensure the accuracy of a PCB footprint?

To ensure footprint accuracy, always refer to the component manufacturer’s datasheet for precise dimensions and specifications. Double-check the footprint against the datasheet and perform a visual inspection. Creating a prototype PCB and testing with the actual component is the best way to validate the footprint. -

What should I do if I can’t find a footprint for a specific component?

If you cannot find a pre-built footprint for a specific component, you may need to create a custom footprint. Refer to the component datasheet and use footprint creation tools in your EDA software to design the footprint according to the specifications. -

How often should I update my PCB footprint library?

It is recommended to regularly update your PCB footprint library to keep up with new component releases and any changes in industry standards. The frequency of updates may vary depending on the pace of new component introductions in your specific industry or project requirements. Conducting periodic reviews and incorporating updates as needed can help maintain an up-to-date and reliable footprint library.

No responses yet