Introduction to PCB Violations Report

In the world of Printed Circuit Board (PCB) design, ensuring the integrity and manufacturability of the final product is of utmost importance. One crucial aspect of this process is identifying and resolving design rule violations. The PCB DLG Violations Report is a comprehensive tool that helps designers and engineers detect and analyze various types of violations in their PCB designs. This article will delve into the details of the DLG Violation Details AD, a critical component of the PCB Violations Report.

What is a PCB Violation?

A PCB violation refers to any deviation from the predefined design rules and guidelines set forth by the PCB manufacturer or the industry standards. These violations can range from simple spacing issues to more complex problems related to signal integrity and electromagnetic compatibility. Some common types of PCB violations include:

- Clearance violations

- Trace width violations

- Annular ring violations

- Copper pour violations

- Silk screen violations

Failing to address these violations can lead to manufacturing delays, increased costs, and even functional failures of the final PCB assembly.

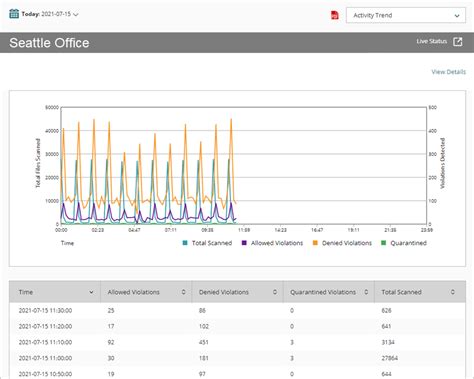

The Role of DLG Violation Details AD

The DLG Violation Details AD is an essential part of the PCB Violations Report that provides a detailed analysis of each detected violation. This section of the report offers a comprehensive breakdown of the violation, including its location, severity, and potential impact on the overall design.

Violation Location

One of the primary functions of the DLG Violation Details AD is to pinpoint the exact location of each violation within the PCB design. This information is crucial for designers and engineers to quickly identify and address the issue. The location data typically includes:

- Layer: The specific layer on which the violation occurs (e.g., Top Layer, Bottom Layer, Inner Layers)

- Coordinates: The X and Y coordinates of the violation relative to the PCB origin

- Component: If the violation is associated with a specific component, its reference designator is provided

Having accurate location data streamlines the debugging process and allows for targeted corrections.

Violation Severity

Not all PCB violations are created equal. Some may have a minor impact on the design, while others can lead to catastrophic failures. The DLG Violation Details AD assigns a severity level to each violation based on its potential consequences. The severity levels can be categorized as follows:

- Critical: Violations that can cause significant manufacturing issues or functional failures

- Major: Violations that may affect the performance or reliability of the PCB

- Minor: Violations that have minimal impact on the design but should still be addressed

By prioritizing violations based on their severity, designers can focus their efforts on the most pressing issues first.

Violation Description

In addition to location and severity, the DLG Violation Details AD provides a concise description of each violation. This description helps designers understand the nature of the problem and the specific design rule that has been violated. Some examples of violation descriptions include:

- “Clearance violation between trace and pad”

- “Trace width below minimum allowed value”

- “Insufficient annular ring for via”

These descriptions serve as a starting point for designers to investigate the root cause of the violation and determine the appropriate course of action.

Benefits of Using DLG Violation Details AD

Incorporating the DLG Violation Details AD into the PCB design workflow offers several key benefits:

-

Early Detection of Issues: By identifying violations early in the design process, designers can avoid costly manufacturing delays and rework.

-

Improved Design Quality: Addressing violations based on their severity and potential impact leads to higher-quality PCB designs that meet industry standards and manufacturer requirements.

-

Time and Cost Savings: The detailed information provided by the DLG Violation Details AD allows for targeted corrections, reducing the time and effort required to resolve issues.

-

Enhanced Collaboration: The clear and concise violation details facilitate effective communication between design teams, manufacturers, and other stakeholders.

Best Practices for Resolving PCB Violations

When working with the DLG Violation Details AD, consider the following best practices to efficiently resolve PCB violations:

-

Prioritize Violations: Focus on addressing critical and major violations first, as they have the greatest potential impact on the design.

-

Use Design Rule Check (DRC) Tools: Leverage DRC tools within your PCB design software to automatically detect and report violations.

-

Collaborate with Manufacturers: Consult with your PCB manufacturer to understand their specific design requirements and guidelines.

-

Implement Design for Manufacturability (DFM) Principles: Incorporate DFM principles into your design process to minimize the occurrence of violations.

-

Continuously Monitor and Update: Regularly run the PCB Violations Report and review the DLG Violation Details AD to ensure that your design remains compliant throughout the development cycle.

FAQ

-

Q: What is the difference between critical and major violations in the DLG Violation Details AD?

A: Critical violations are those that can cause significant manufacturing issues or functional failures, while major violations may affect the performance or reliability of the PCB but are less severe than critical violations. -

Q: How can I quickly locate a specific violation in my PCB design?

A: The DLG Violation Details AD provides the layer, coordinates, and component information for each violation, allowing you to easily locate the issue within your PCB design software. -

Q: Can the DLG Violation Details AD help me prioritize which violations to address first?

A: Yes, the DLG Violation Details AD assigns a severity level (critical, major, or minor) to each violation, helping you prioritize your efforts based on the potential impact of the violation. -

Q: How often should I run the PCB Violations Report and review the DLG Violation Details AD?

A: It is recommended to run the PCB Violations Report and review the DLG Violation Details AD regularly throughout the design process, especially after making significant changes to the design. -

Q: Can the DLG Violation Details AD help me communicate violations to my PCB manufacturer?

A: Yes, the clear and concise violation descriptions provided in the DLG Violation Details AD can facilitate effective communication between design teams and PCB manufacturers, ensuring that everyone is on the same page regarding design requirements and issues.

Conclusion

The DLG Violation Details AD is a vital component of the PCB Violations Report, providing designers and engineers with the necessary information to identify, analyze, and resolve design rule violations efficiently. By leveraging the detailed location, severity, and description data offered by this tool, PCB designers can improve the quality of their designs, reduce manufacturing delays, and ultimately create more reliable and cost-effective products. Incorporating the DLG Violation Details AD into the PCB design workflow, along with following best practices for resolving violations, will help ensure the success of your PCB projects.

No responses yet