Introduction to Watchdog Timers

In the world of electronic systems, ensuring reliable operation is paramount. One of the critical components that contribute to system reliability is the watchdog timer (WDT). A watchdog timer is a hardware or software mechanism that monitors the system’s operation and takes corrective action if the system becomes unresponsive or enters an unexpected state. In this article, we will explore the role of external watchdog timers in PCB design and provide insights into whether you should include one in your board design.

What is a Watchdog Timer?

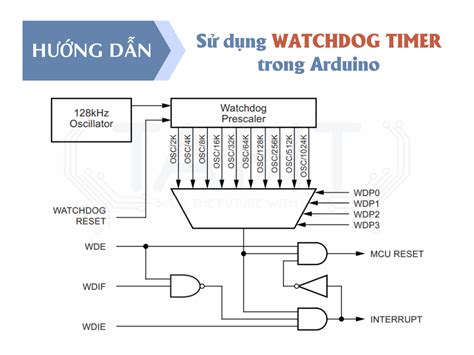

A watchdog timer is essentially a countdown timer that is regularly reset by the system’s software during normal operation. If the software fails to reset the timer within a predefined time window, the watchdog timer assumes that the system has become unresponsive or has encountered an error. In such cases, the watchdog timer triggers a system reset or initiates a predefined recovery mechanism to bring the system back to a known stable state.

Types of Watchdog Timers

There are two main types of watchdog timers:

-

Software Watchdog Timer: A software watchdog timer is implemented entirely in software. It relies on the system’s software to periodically reset the timer. If the software fails to reset the timer, it indicates a software malfunction, and the watchdog timer takes corrective action.

-

Hardware Watchdog Timer: A hardware watchdog timer is a dedicated hardware component, often an external IC, that operates independently of the system’s software. The software must periodically reset the hardware watchdog timer to prevent it from triggering a system reset.

Advantages of Using an External Watchdog Timer

Including an external watchdog timer in your PCB design offers several advantages:

1. Independent Operation

An external watchdog timer operates independently of the system’s main processor and software. This independence ensures that even if the main processor or software becomes unresponsive, the watchdog timer can still detect the issue and initiate a system reset. The external watchdog timer acts as a separate line of defense, providing an additional layer of reliability.

2. Improved System Reliability

By incorporating an external watchdog timer, you can significantly enhance the overall reliability of your system. The watchdog timer continuously monitors the system’s operation and takes action if it detects any abnormalities. This proactive approach helps prevent system hangs, deadlocks, or other unexpected behaviors that could compromise the system’s functionality.

3. Faster Recovery

In the event of a system malfunction, an external watchdog timer can quickly detect the issue and initiate a system reset. This fast response time minimizes downtime and ensures that the system recovers promptly. Without a watchdog timer, a system hang or deadlock could persist indefinitely, requiring manual intervention to resolve the issue.

4. Flexibility and Customization

External watchdog timers offer flexibility in terms of configuration and customization. You can select a watchdog timer IC that meets your specific requirements, such as timeout period, reset behavior, and additional features like windowed operation or programmable timeout intervals. This flexibility allows you to tailor the watchdog timer’s behavior to your system’s needs.

Considerations for Implementing an External Watchdog Timer

While including an external watchdog timer in your PCB design offers benefits, there are several considerations to keep in mind:

1. Selecting the Right Watchdog Timer IC

Choosing the appropriate watchdog timer IC is crucial. Consider factors such as the timeout period range, reset behavior, power consumption, and package size. Ensure that the selected IC is compatible with your system’s voltage levels and interfaces properly with your microcontroller or processor.

2. Proper Configuration and Timeout Settings

Configuring the external watchdog timer correctly is essential for effective operation. Determine an appropriate timeout period based on your system’s requirements. The timeout period should be long enough to allow the software to complete its tasks and reset the timer, but short enough to detect and respond to system hangs or malfunctions promptly.

3. Software Integration

Integrating the external watchdog timer with your system’s software is crucial. Ensure that your software includes the necessary code to periodically reset the watchdog timer within the configured timeout period. Failing to reset the timer correctly can lead to unintended system resets.

4. Reset Behavior and System Recovery

Consider how the system should behave when the external watchdog timer triggers a reset. Define a proper reset sequence and ensure that the system recovers gracefully. This may involve initializing critical components, restoring default settings, or performing necessary cleanup tasks.

5. Testing and Validation

Thorough testing and validation of the external watchdog timer implementation are essential. Simulate various scenarios, including normal operation and induced system hangs or malfunctions, to verify that the watchdog timer detects and responds appropriately. Conduct rigorous testing to ensure the reliability and effectiveness of the watchdog timer mechanism.

PCB Design Considerations for External Watchdog Timers

When incorporating an external watchdog timer into your PCB design, consider the following:

1. Placement and Routing

Pay attention to the placement and routing of the watchdog timer IC on your PCB. Position the IC close to the microcontroller or processor it monitors to minimize signal integrity issues. Ensure proper routing of the reset and control signals to avoid any signal degradation or interference.

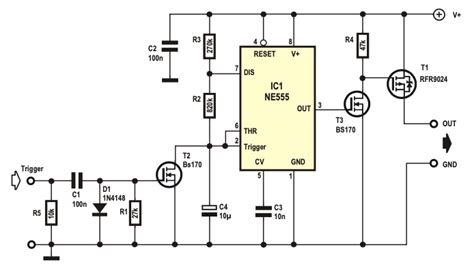

2. Power Supply

Provide a stable and reliable power supply to the external watchdog timer IC. Consider using a separate power domain or a dedicated voltage regulator to ensure the watchdog timer remains operational even if the main system power is compromised.

3. Reset Signal Integrity

The reset signal generated by the external watchdog timer is critical for system recovery. Ensure that the reset signal is properly routed and has sufficient drive strength to reset the necessary components. Consider using a reset IC or a dedicated reset circuit to handle the reset signal distribution.

4. Debugging and Test Points

Include debugging and test points in your PCB design to facilitate testing and troubleshooting of the external watchdog timer. Provide access to the watchdog timer’s control and status signals, allowing you to monitor its operation and diagnose any issues during development or field testing.

Real-World Applications and Examples

External watchdog timers find applications in various domains where system reliability is critical. Some real-world examples include:

1. Automotive Electronics

In automotive systems, external watchdog timers are commonly used to ensure the reliable operation of critical components such as engine control units (ECUs), safety systems, and infotainment systems. The watchdog timer helps detect and recover from software or hardware malfunctions, enhancing the overall safety and reliability of the vehicle.

2. Industrial Control Systems

Industrial control systems, such as programmable logic controllers (PLCs) and supervisory control and data acquisition (SCADA) systems, often employ external watchdog timers. These timers monitor the operation of the control software and hardware, ensuring that the system remains responsive and recovers from any abnormalities.

3. Medical Devices

Medical devices, particularly those involved in life-critical functions, rely on external watchdog timers to ensure reliable operation. Watchdog timers help detect and mitigate software or hardware failures, preventing potential harm to patients and ensuring the device’s integrity.

4. Aerospace and Defense Systems

In aerospace and defense applications, external watchdog timers are used to monitor mission-critical systems, such as flight control computers, communication systems, and avionics. The watchdog timer helps maintain system stability and initiates recovery mechanisms in case of any anomalies.

Frequently Asked Questions (FAQ)

-

Q: Is an external watchdog timer necessary for all PCB designs?

A: While an external watchdog timer provides additional reliability, it may not be necessary for all PCB designs. The decision to include one depends on the criticality of the system, the consequences of system failure, and the required level of reliability. -

Q: Can a software watchdog timer replace an external hardware watchdog timer?

A: A software watchdog timer can provide some level of system monitoring, but it is not as reliable as an external hardware watchdog timer. Software watchdog timers are still susceptible to software bugs, deadlocks, or system hangs, whereas an external hardware watchdog timer operates independently of the system software. -

Q: How do I determine the appropriate timeout period for my watchdog timer?

A: The timeout period should be based on the system’s requirements and the expected execution time of critical tasks. It should be long enough to allow the software to complete its tasks and reset the timer, but short enough to detect and respond to system hangs or malfunctions promptly. Determine the timeout period through careful analysis and testing of your system. -

Q: Can an external watchdog timer detect all types of system failures?

A: While an external watchdog timer is effective in detecting system hangs, deadlocks, or unresponsive behavior, it may not detect all types of system failures. For example, it cannot detect logical errors in software that do not cause the system to become unresponsive. Comprehensive testing and error handling mechanisms should be implemented alongside the watchdog timer. -

Q: Are there any disadvantages to using an external watchdog timer?

A: The main disadvantage of using an external watchdog timer is the additional cost and board space required for the watchdog timer IC. It also requires proper configuration, software integration, and testing to ensure effective operation. However, the benefits of improved system reliability often outweigh these considerations in critical applications.

Conclusion

Including an external watchdog timer in your PCB design can significantly enhance the reliability and robustness of your system. By independently monitoring the system’s operation and initiating corrective actions when necessary, an external watchdog timer helps prevent system hangs, deadlocks, and other unexpected behaviors. However, the decision to include an external watchdog timer should be based on the specific requirements and criticality of your application.

When incorporating an external watchdog timer, careful consideration should be given to selecting the appropriate watchdog timer IC, configuring it correctly, and integrating it with your system’s software. Proper PCB design practices, such as placement, routing, and power supply considerations, are essential for the effective operation of the watchdog timer.

Real-world applications in various domains, including automotive electronics, industrial control systems, medical devices, and aerospace and defense systems, demonstrate the importance of external watchdog timers in ensuring system reliability.

By understanding the benefits, considerations, and best practices associated with external watchdog timers, you can make an informed decision on whether to include one in your PCB design. Ultimately, the inclusion of an external watchdog timer can provide an additional layer of protection and peace of mind, contributing to the overall reliability and dependability of your electronic system.

| Component | Purpose |

|---|---|

| Watchdog Timer IC | Monitors system operation and initiates corrective actions |

| Reset Circuit | Handles reset signal distribution and ensures signal integrity |

| Power Supply | Provides stable and reliable power to the watchdog timer IC |

| Control Signals | Interfaces between the watchdog timer and the system |

| Debugging Test Points | Facilitates testing and troubleshooting of the watchdog timer |

No responses yet