Understanding PCB Edge Clearance and Its Importance

When designing printed circuit boards (PCBs), one crucial aspect to consider is the edge clearance. PCB edge clearance refers to the minimum distance between the edge of the board and any copper features, such as traces, pads, or vias. Maintaining proper edge clearance is essential for several reasons:

-

Manufacturing process: Adequate edge clearance ensures that the PCB can be safely handled during the manufacturing process without damaging any components or copper features near the edges.

-

Mechanical stability: Sufficient edge clearance helps maintain the mechanical stability of the PCB by preventing any damage or delamination caused by stress or impact near the edges.

-

Electrical safety: Proper edge clearance reduces the risk of short circuits or electrical failures caused by exposed copper near the edges of the board.

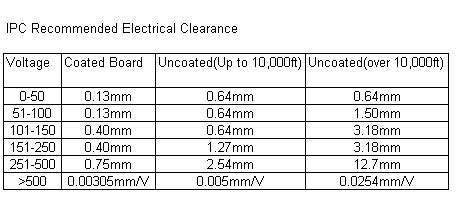

Recommended PCB Edge Clearance Values

The recommended edge clearance values may vary depending on the PCB manufacturer and the specific requirements of the project. However, the following table provides general guidelines for edge clearance based on the copper weight and board thickness:

| Copper Weight (oz) | Board Thickness (mm) | Minimum Edge Clearance (mm) |

|---|---|---|

| 1/2 | 0.8 – 1.6 | 0.5 |

| 1 | 0.8 – 2.4 | 0.7 |

| 2 | 1.6 – 3.2 | 1.0 |

| 3 | 2.4 – 4.0 | 1.2 |

| 4 | 3.2 – 4.8 | 1.5 |

It is always advisable to consult with your PCB manufacturer to determine the specific edge clearance requirements for your project.

Design Techniques to Maximize PCB Edge Clearance

When designing PCBs, there are several techniques you can employ to maximize edge clearance and ensure the optimal performance and reliability of your board. Some of these techniques include:

1. Proper Component Placement

One of the most effective ways to maximize edge clearance is to carefully plan the placement of components on the PCB. By strategically positioning components away from the edges of the board, you can create more space for copper features and minimize the risk of damage or electrical issues.

Tips for proper component placement:

- Place larger components towards the center of the board

- Keep smaller components grouped together and away from edges

- Consider the orientation of components to optimize space utilization

2. Use of Copper Pours

Copper pours, also known as ground planes or power planes, are large areas of copper that are used to provide a low-impedance path for ground or power connections. By utilizing copper pours, you can not only improve the electrical performance of your PCB but also maximize edge clearance.

Benefits of using copper pours:

- Reduces the need for individual traces near the edges of the board

- Provides better shielding and reduces electromagnetic interference (EMI)

- Improves heat dissipation and thermal management

3. Optimizing Trace Routing

Efficient trace routing is another key factor in maximizing PCB edge clearance. By carefully planning the paths of your traces and minimizing their proximity to the edges of the board, you can reduce the risk of damage or electrical issues.

Tips for optimizing trace routing:

- Use 45-degree angles instead of 90-degree angles to reduce stress on traces

- Avoid running traces parallel to the edges of the board

- Use via stitching to provide additional mechanical support for traces near edges

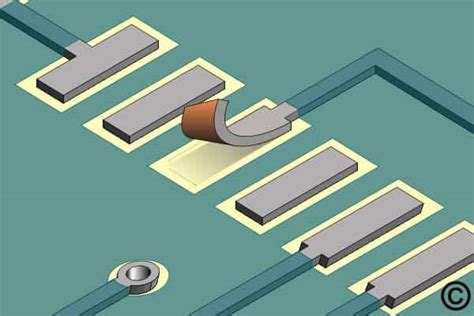

4. Implementing Edge Plating

Edge plating is a process in which a conductive layer, typically copper, is applied to the edges of the PCB. This technique can help improve the mechanical strength and durability of the board, as well as provide additional protection against damage or delamination.

Advantages of edge plating:

- Enhances the mechanical stability of the PCB

- Provides a conductive path for grounding and shielding

- Helps prevent moisture ingress and corrosion

Advanced Techniques for Extending PCB Edge Clearance

In addition to the basic design techniques mentioned above, there are several advanced methods that can be used to further extend PCB edge clearance and improve the overall performance and reliability of your board.

1. Blind and Buried Vias

Blind and buried vias are specialized types of vias that are used to connect inner layers of a multi-layer PCB without penetrating the entire thickness of the board. By utilizing blind and buried vias, you can free up more space on the outer layers of the PCB, allowing for greater edge clearance.

Types of blind and buried vias:

- Blind via: Connects an outer layer to an inner layer, but does not penetrate the entire board thickness

- Buried via: Connects two or more inner layers, but does not extend to the outer layers

Advantages of using blind and buried vias:

- Increases available space on outer layers for components and routing

- Reduces the overall size and weight of the PCB

- Improves signal integrity and reduces crosstalk

2. High-Density Interconnect (HDI) PCBs

High-density interconnect (HDI) PCBs are a type of advanced PCB technology that utilizes a combination of microvias, blind and buried vias, and fine-pitch components to achieve higher component density and improved performance.

Features of HDI PCBs:

- Microvias with diameters less than 150 microns

- Fine-pitch components with lead spacing less than 0.5mm

- Sequential lamination process for multi-layer construction

Benefits of using HDI technology:

- Enables higher component density and smaller board sizes

- Improves signal integrity and reduces signal delays

- Allows for greater design flexibility and customization

3. Rigid-Flex PCBs

Rigid-flex PCBs are a hybrid type of PCB that combines rigid and flexible substrates in a single board. This technology allows for greater design flexibility and can help maximize edge clearance by allowing components to be placed in unconventional locations.

Advantages of rigid-flex PCBs:

- Enables 3D packaging and non-planar designs

- Reduces the need for connectors and cable assemblies

- Improves reliability and reduces the risk of mechanical failures

Case Studies: Successful Implementation of Edge Clearance Techniques

To illustrate the effectiveness of the various edge clearance techniques discussed in this article, let’s take a look at some real-world case studies where these methods have been successfully implemented.

Case Study 1: Medical Device PCB Design

In this case study, a medical device manufacturer was faced with the challenge of designing a compact, high-density PCB for a new implantable device. The limited space available within the device housing required the PCB to have minimal edge clearance while still maintaining optimal performance and reliability.

Solution:

– Implemented HDI technology with microvias and fine-pitch components

– Utilized blind and buried vias to maximize space on outer layers

– Employed strategic component placement and copper pours for improved shielding

Result:

The resulting PCB design successfully met the stringent size and performance requirements of the medical device, while maintaining adequate edge clearance for manufacturing and long-term reliability.

Case Study 2: Automotive ECU PCB Design

An automotive electronics manufacturer was tasked with designing a new engine control unit (ECU) PCB that could withstand the harsh environmental conditions and vibrations encountered in vehicle applications. The design required robust edge clearance to prevent any damage or electrical failures due to mechanical stress.

Solution:

– Utilized edge plating to enhance the mechanical stability of the PCB

– Implemented rigid-flex technology to allow for non-planar packaging

– Optimized trace routing and via stitching for improved mechanical support

Result:

The final ECU PCB design demonstrated excellent durability and reliability, even under the demanding conditions of automotive applications. The enhanced edge clearance techniques employed in the design helped prevent any mechanical or electrical failures, ensuring optimal performance throughout the product lifecycle.

FAQ

1. What is PCB edge clearance, and why is it important?

PCB edge clearance refers to the minimum distance between the edge of the board and any copper features, such as traces, pads, or vias. Maintaining proper edge clearance is essential for ensuring the manufacturability, mechanical stability, and electrical safety of the PCB.

2. How can I determine the appropriate edge clearance for my PCB design?

The recommended edge clearance values may vary depending on the specific requirements of your project and the capabilities of your PCB manufacturer. As a general guideline, the minimum edge clearance ranges from 0.5mm to 1.5mm, based on the copper weight and board thickness. Always consult with your manufacturer to determine the optimal edge clearance for your design.

3. What are some effective techniques for maximizing PCB edge clearance?

Some effective techniques for maximizing PCB edge clearance include:

– Proper component placement

– Use of copper pours

– Optimizing trace routing

– Implementing edge plating

– Utilizing blind and buried vias

– Adopting HDI technology

– Employing rigid-flex PCBs

4. How can HDI technology help extend PCB edge clearance?

HDI (High-Density Interconnect) technology utilizes microvias, blind and buried vias, and fine-pitch components to achieve higher component density and improved performance. By using these advanced features, HDI PCBs can free up more space on the outer layers, allowing for greater edge clearance and design flexibility.

5. Are there any real-world examples of successful edge clearance implementation?

Yes, there are numerous case studies showcasing the successful implementation of edge clearance techniques in various industries. For example, a medical device manufacturer was able to design a compact, high-density PCB with minimal edge clearance by utilizing HDI technology and strategic component placement. Similarly, an automotive electronics manufacturer employed edge plating, rigid-flex technology, and optimized trace routing to create a durable and reliable ECU PCB that could withstand harsh environmental conditions.

In conclusion, understanding and implementing proper PCB edge clearance techniques is crucial for ensuring the optimal performance, reliability, and manufacturability of your PCB designs. By adopting a combination of basic and advanced techniques, such as strategic component placement, copper pours, HDI technology, and rigid-flex PCBs, you can effectively maximize edge clearance and push the boundaries of PCB design. Always collaborate closely with your PCB manufacturer to determine the best approach for your specific project requirements and ensure the success of your design.

No responses yet