Introduction

Printed Circuit Board (PCB) design and Bill of Materials (BOM) management are critical aspects of low volume manufacturing. Ensuring profitability in this context requires careful planning, attention to detail, and effective strategies for optimizing the design and manufacturing processes. In this article, we will explore the key considerations and best practices for PCB design and BOM management in low volume manufacturing.

The Importance of PCB Design in Low Volume Manufacturing

Optimizing PCB Design for Manufacturing

Effective PCB design is essential for ensuring the manufacturability and reliability of the final product. In low volume manufacturing, it is particularly important to optimize the design for manufacturing (DFM) to minimize costs and reduce the risk of defects. Some key considerations for DFM include:

- Choosing appropriate component sizes and packages

- Ensuring adequate spacing between components

- Minimizing the number of layers in the PCB

- Using standard materials and processes wherever possible

Designing for Testability

Designing for testability (DFT) is another important aspect of PCB design in low volume manufacturing. By incorporating testability features into the design, such as test points and boundary scan, manufacturers can reduce the time and cost associated with testing and debugging. This can help to improve overall profitability by reducing the number of defective units and minimizing the need for rework.

Leveraging Design Reuse

In low volume manufacturing, leveraging design reuse can be an effective way to reduce development costs and improve profitability. By reusing existing designs or design elements, manufacturers can minimize the time and effort required for new product development. This can be particularly beneficial for products that share common features or functionality.

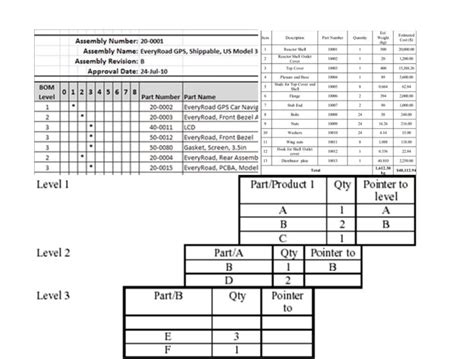

Effective BOM Management Strategies

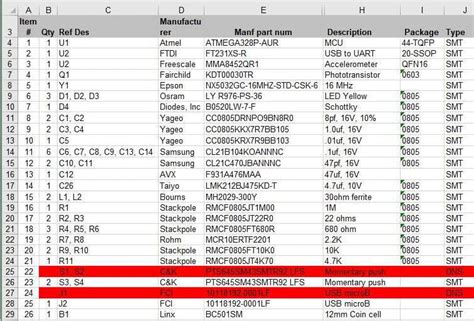

Creating Accurate and Complete BOMs

An accurate and complete BOM is essential for ensuring the smooth and efficient procurement and manufacturing processes. In low volume manufacturing, where margins may be tight, any errors or omissions in the BOM can have a significant impact on profitability. Some key considerations for creating effective BOMs include:

- Including all necessary components and materials

- Specifying the correct quantities and units of measure

- Providing detailed descriptions and specifications for each item

- Ensuring consistency and accuracy across all documentation

Optimizing Inventory Management

Effective inventory management is critical for minimizing costs and ensuring the timely availability of components and materials in low volume manufacturing. Some strategies for optimizing inventory management include:

- Implementing just-in-time (JIT) inventory practices

- Establishing minimum and maximum stock levels for each item

- Regularly reviewing and adjusting inventory levels based on demand forecasts

- Leveraging vendor-managed inventory (VMI) programs where appropriate

Managing Supplier Relationships

Building strong relationships with suppliers is essential for ensuring the timely and cost-effective procurement of components and materials in low volume manufacturing. Some strategies for managing supplier relationships include:

- Establishing clear communication channels and expectations

- Negotiating favorable terms and pricing based on volume commitments

- Implementing quality control measures to ensure consistent quality and reliability

- Regularly evaluating supplier performance and making adjustments as needed

Integrating PCB Design and BOM Management

The Benefits of Integration

Integrating PCB design and BOM management can provide significant benefits for low volume manufacturers. By ensuring that the design and BOM are aligned and synchronized, manufacturers can reduce the risk of errors and inconsistencies, improve the efficiency of procurement and manufacturing processes, and ultimately enhance profitability.

Tools and Technologies for Integration

There are a variety of tools and technologies available to support the integration of PCB design and BOM management. These may include:

- Electronic design automation (EDA) software for PCB design

- Product lifecycle management (PLM) systems for BOM management

- Enterprise resource planning (ERP) systems for inventory and procurement management

- Data exchange standards and protocols, such as IPC-2581 and ODB++

| Tool/Technology | Description |

|---|---|

| EDA Software | Used for PCB design, schematic capture, and layout |

| PLM Systems | Manage product data, including BOMs and design files |

| ERP Systems | Manage inventory, procurement, and other business processes |

| Data Exchange Standards | Facilitate the exchange of design and BOM data between systems |

Best Practices for Integration

To effectively integrate PCB design and BOM management, manufacturers should follow best practices such as:

- Establishing clear roles and responsibilities for design and BOM management

- Implementing standardized processes and workflows for design and BOM creation and maintenance

- Ensuring regular communication and collaboration between design and procurement teams

- Leveraging automation and data exchange technologies to minimize manual effort and reduce errors

Case Studies and Examples

Company A: Optimizing PCB Design for Low Volume Manufacturing

Company A, a manufacturer of specialized medical devices, faced challenges in ensuring the profitability of their low volume products. By implementing a comprehensive DFM strategy, including the use of standard components and processes, they were able to reduce manufacturing costs by 20% and improve overall product reliability.

Company B: Streamlining BOM Management for Improved Efficiency

Company B, a contract manufacturer of electronic assemblies, struggled with inconsistencies and errors in their BOM management processes. By implementing a PLM system and establishing standardized workflows for BOM creation and maintenance, they were able to reduce BOM errors by 75% and improve on-time delivery to their customers.

FAQ

-

Q: What are some key considerations for PCB design in low volume manufacturing?

A: Some key considerations for PCB design in low volume manufacturing include optimizing for manufacturability, designing for testability, and leveraging design reuse to reduce development costs. -

Q: Why is an accurate and complete BOM important in low volume manufacturing?

A: An accurate and complete BOM is essential for ensuring the smooth and efficient procurement and manufacturing processes. In low volume manufacturing, where margins may be tight, any errors or omissions in the BOM can have a significant impact on profitability. -

Q: How can manufacturers optimize inventory management in low volume manufacturing?

A: Some strategies for optimizing inventory management in low volume manufacturing include implementing just-in-time (JIT) inventory practices, establishing minimum and maximum stock levels for each item, regularly reviewing and adjusting inventory levels based on demand forecasts, and leveraging vendor-managed inventory (VMI) programs where appropriate. -

Q: What are the benefits of integrating PCB design and BOM management?

A: Integrating PCB design and BOM management can provide significant benefits for low volume manufacturers, including reducing the risk of errors and inconsistencies, improving the efficiency of procurement and manufacturing processes, and ultimately enhancing profitability. -

Q: What are some best practices for integrating PCB design and BOM management?

A: To effectively integrate PCB design and BOM management, manufacturers should establish clear roles and responsibilities for design and BOM management, implement standardized processes and workflows for design and BOM creation and maintenance, ensure regular communication and collaboration between design and procurement teams, and leverage automation and data exchange technologies to minimize manual effort and reduce errors.

Conclusion

PCB design and BOM management are critical aspects of low volume manufacturing that require careful planning and execution to ensure profitability. By optimizing PCB design for manufacturability, designing for testability, and leveraging design reuse, manufacturers can reduce development costs and improve product reliability. Effective BOM management strategies, including creating accurate and complete BOMs, optimizing inventory management, and managing supplier relationships, can help to minimize costs and ensure the timely availability of components and materials.

Integrating PCB design and BOM management through the use of tools and technologies such as EDA software, PLM systems, and data exchange standards can provide significant benefits for low volume manufacturers. By following best practices for integration, manufacturers can reduce the risk of errors and inconsistencies, improve the efficiency of procurement and manufacturing processes, and ultimately enhance profitability.

As demonstrated by the case studies and examples provided, implementing effective strategies for PCB design and BOM management can have a significant impact on the profitability of low volume manufacturing. By carefully considering the unique challenges and opportunities of this context and adopting best practices and technologies for design and BOM management, manufacturers can position themselves for success in this competitive and demanding market.

No responses yet