What is PCB Assembly?

PCB assembly is the process of mounting electronic components onto a printed circuit board. The components are placed on the board according to a predetermined design and then soldered in place to create a functional electronic circuit. The process can be done manually or using automated machines, depending on the complexity of the design and the volume of production required.

Types of PCB Assembly

There are two main types of PCB assembly:

-

Through-hole assembly (THA): This method involves inserting the leads of components through holes drilled in the PCB and soldering them in place on the opposite side of the board. THA is often used for larger components or those that require more mechanical stability.

-

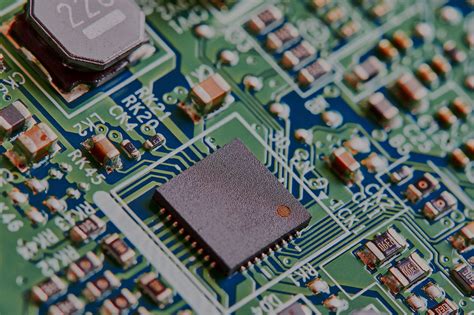

Surface mount assembly (SMT): In this method, components are placed directly on the surface of the PCB and soldered in place using a reflow oven. SMT allows for smaller components and higher density of components on the board, making it the preferred method for most modern electronic devices.

The PCB Assembly Process

The PCB assembly process can be broken down into several steps:

1. PCB design and Fabrication

Before the assembly process can begin, the PCB must be designed and fabricated. The design process involves creating a schematic diagram of the electronic circuit and then laying out the components and traces on the board using specialized software. The design is then sent to a PCB fabrication facility, where the board is manufactured according to the specifications.

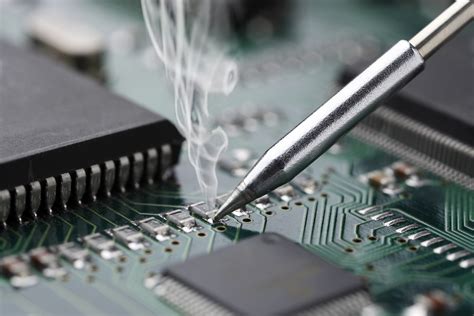

2. Solder Paste Application

Once the PCB is fabricated, a thin layer of solder paste is applied to the pads where the components will be placed. The solder paste is a mixture of tiny solder balls and flux, which helps to clean the surfaces and prevent oxidation during the soldering process.

3. Component Placement

The next step is to place the components onto the PCB. This can be done manually for small batches or low-complexity designs, but most modern PCB assembly is done using automated pick-and-place machines. These machines use computer vision and robotic arms to pick up components from reels or trays and place them onto the board with high precision and speed.

4. Reflow Soldering

After the components are placed, the PCB is sent through a reflow oven. The oven heats the board to a specific temperature profile, melting the solder paste and creating a strong bond between the components and the PCB. The temperature profile is carefully controlled to ensure that the components are not damaged during the process.

5. Inspection and Testing

Once the soldering process is complete, the PCB undergoes a series of inspections and tests to ensure that it is functioning correctly. This may include visual inspection, automated optical inspection (AOI), and functional testing. Any defects or issues found during this stage are corrected before the PCB is sent for final assembly into the end product.

Factors to Consider When Choosing a PCB Assembly Service Provider

When choosing a PCB assembly service provider, there are several factors to consider:

1. Experience and Expertise

Look for a provider with a proven track record of experience and expertise in PCB assembly. They should have a deep understanding of the latest technologies and best practices in the industry.

2. Quality Control

Quality is critical in PCB assembly, as even small defects can lead to device failure or malfunction. Choose a provider with strict quality control measures in place, such as ISO certification and regular testing and inspection throughout the assembly process.

3. Turnaround Time

The speed at which a provider can complete your PCB assembly order is important, especially if you are working on a tight deadline. Look for a provider that can offer fast turnaround times without compromising on quality.

4. Cost

PCB assembly can be a significant cost in the production of electronic devices. While it is important to find a provider that offers competitive pricing, be wary of those that offer prices that seem too good to be true. They may be cutting corners on quality or using inferior components.

5. Customer Service

Good communication and customer service are essential when working with a PCB assembly provider. Look for a provider that is responsive to your needs and willing to work with you to ensure that your project is a success.

Benefits of PCB Assembly

PCB assembly offers several benefits over other methods of electronic circuit construction:

1. Consistency and Reliability

Automated PCB assembly processes ensure that each board is assembled to the same high standard, reducing the risk of human error and ensuring consistent performance across all devices.

2. Miniaturization

PCB assembly allows for the use of smaller components and higher density of components on the board, enabling the creation of more compact and lightweight electronic devices.

3. Cost Efficiency

While the initial setup costs for PCB assembly can be high, the process is highly scalable and can offer significant cost savings over manual assembly methods for large production runs.

4. Faster Time to Market

Automated PCB assembly processes can significantly reduce the time required to bring a new product to market, enabling companies to stay competitive in fast-moving industries.

Common PCB Assembly Challenges and Solutions

Despite its many benefits, PCB assembly can also present some challenges. Here are some common issues and their solutions:

1. Solder Bridging

Solder bridging occurs when excess solder creates an unintended connection between two or more pads on the PCB. This can be caused by improper solder paste application or incorrect reflow oven settings. To prevent solder bridging, ensure that the solder paste is applied evenly and in the correct amount, and that the reflow oven profile is optimized for the specific components and PCB design.

2. Component Shifting

Component shifting can occur during the reflow process, causing components to move out of their intended position on the PCB. This can be caused by improper placement or insufficient solder paste. To prevent component shifting, ensure that the pick-and-place machine is properly calibrated and that the solder paste is applied evenly and in sufficient quantity.

3. Tombstoning

Tombstoning is a phenomenon where a component lifts up on one end during the reflow process, creating an open circuit. This can be caused by uneven heating or incorrect component placement. To prevent tombstoning, ensure that the reflow oven profile is optimized for the specific components and PCB design, and that the components are placed correctly on the board.

FAQ

1. What is the difference between PCB assembly and PCB fabrication?

PCB fabrication is the process of manufacturing the bare PCB, while PCB assembly involves mounting and soldering the electronic components onto the fabricated board.

2. Can PCB assembly be done manually?

Yes, PCB assembly can be done manually for small batches or low-complexity designs. However, most modern PCB assembly is done using automated machines for higher efficiency and accuracy.

3. What is the typical turnaround time for PCB assembly?

The turnaround time for PCB assembly varies depending on the complexity of the design and the volume of production required. Typical turnaround times range from a few days to several weeks.

4. How much does PCB assembly cost?

The cost of PCB assembly depends on several factors, including the complexity of the design, the volume of production, and the specific components used. In general, larger production runs will have a lower per-unit cost than smaller batches.

5. What certifications should I look for in a PCB assembly provider?

Look for a PCB assembly provider with certifications such as ISO 9001 for quality management and IPC-A-610 for acceptability of electronic assemblies. These certifications demonstrate a commitment to quality and adherence to industry standards.

Conclusion

PCB assembly is a critical process in the production of electronic devices, enabling the creation of reliable, high-performance circuits in a cost-effective and scalable manner. When choosing a PCB assembly service provider, it is important to consider factors such as experience, quality control, turnaround time, cost, and customer service. By understanding the PCB assembly process and its challenges, you can ensure that your electronic devices are manufactured to the highest standards of quality and reliability.

No responses yet