Introduction to PCB Assembly

PCB (Printed Circuit Board) assembly is the process of soldering or mounting electronic components onto a printed circuit board. This process is crucial in the manufacturing of electronic devices, as it determines the functionality, reliability, and quality of the final product. In this article, we will delve into the various aspects of PCB assembly, including the types of PCB assembly, the process involved, and the factors to consider when choosing a PCB assembly service provider.

Types of PCB Assembly

There are three main types of PCB assembly:

Through-Hole Assembly (THA)

Through-hole assembly involves inserting component leads through drilled holes in the PCB and soldering them to pads on the opposite side of the board. This method is often used for larger components or when a stronger mechanical connection is required.

Surface Mount Assembly (SMA)

Surface mount assembly involves placing components directly onto pads on the surface of the PCB and soldering them in place. This method allows for smaller components and higher component density compared to through-hole assembly.

Mixed Assembly

Mixed assembly combines both through-hole and surface mount techniques on a single PCB. This method is used when a design requires the benefits of both assembly types.

| Assembly Type | Advantages | Disadvantages |

|---|---|---|

| Through-Hole | – Stronger mechanical connection – Easier to replace components |

– Larger components – Lower component density – More expensive |

| Surface Mount | – Smaller components – Higher component density – Lower cost |

– Weaker mechanical connection – More difficult to replace components |

| Mixed | – Combines benefits of both THA and SMA | – More complex assembly process |

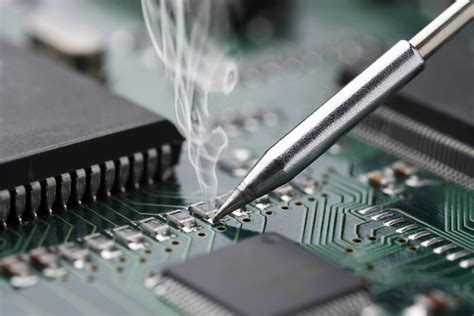

The PCB Assembly Process

The PCB assembly process typically involves the following steps:

-

Solder Paste Application: Solder paste, a mixture of tiny solder spheres and flux, is applied to the pads on the PCB using a stencil or screen printing process.

-

Component Placement: Components are placed onto the PCB, either manually or using automated pick-and-place machines. The machines use computer-aided design (CAD) files to accurately position the components on the board.

-

Reflow Soldering: The PCB is passed through a reflow oven, which heats the board to melt the solder paste and form a permanent connection between the components and the pads.

-

Inspection and Testing: The assembled PCB undergoes visual inspection and electrical testing to ensure proper functionality and quality. Automated optical inspection (AOI) systems and in-circuit testing (ICT) are commonly used methods.

-

Conformal Coating and Potting: If required, a conformal coating or potting compound is applied to protect the PCB and its components from environmental factors such as moisture, dust, and vibration.

Factors to Consider When Choosing a PCB Assembly Service Provider

When selecting a PCB assembly service provider, consider the following factors:

-

Experience and Expertise: Choose a provider with a proven track record in PCB assembly and experience working with designs similar to yours.

-

Quality Control: Ensure that the provider has strict quality control measures in place, such as ISO certifications and advanced inspection and testing equipment.

-

Production Capacity: Verify that the provider has the capacity to meet your production volume and lead time requirements.

-

Technology and Equipment: Select a provider that invests in state-of-the-art technology and equipment to ensure the highest quality and efficiency in the assembly process.

-

Customer Support: Look for a provider that offers excellent customer support, including clear communication, responsiveness, and technical assistance throughout the project.

Benefits of Outsourcing PCB Assembly

Outsourcing PCB assembly offers several benefits:

-

Cost Savings: Outsourcing eliminates the need to invest in expensive assembly equipment, facilities, and skilled labor, reducing overall production costs.

-

Expertise and Quality: PCB assembly service providers have specialized knowledge and experience, ensuring high-quality results and adherence to industry standards.

-

Scalability and Flexibility: Outsourcing allows you to scale production up or down based on demand, without the need to adjust in-house resources.

-

Time Savings: By outsourcing PCB assembly, you can focus on core competencies and product development, while the assembly process is handled by experts.

Common Challenges in PCB Assembly

PCB assembly can present various challenges, including:

-

Component Availability: Shortages or long lead times for specific components can delay the assembly process and impact production schedules.

-

Design Complexity: Highly complex designs with dense component placement or advanced features may require specialized assembly techniques and increase the risk of defects.

-

Miniaturization: As electronic devices become smaller, the demand for miniaturized components and higher density PCBs increases, posing challenges in the assembly process.

-

Thermal Management: Ensuring proper thermal management is crucial to prevent overheating and maintain the reliability of the assembled PCB.

Future Trends in PCB Assembly

The PCB assembly industry is constantly evolving to keep pace with advancements in technology. Some future trends include:

-

Increased Automation: The use of advanced automation technologies, such as robotics and artificial intelligence, will continue to streamline the assembly process and improve efficiency.

-

Adoption of Industry 4.0: The integration of smart factory concepts, such as the Internet of Things (IoT) and real-time data analytics, will enable more intelligent and adaptive PCB assembly processes.

-

Sustainable Practices: There will be a growing emphasis on sustainable PCB assembly practices, including the use of eco-friendly materials and processes, and the adoption of circular economy principles.

-

Advanced Materials: The development of new, high-performance materials, such as graphene and carbon nanotubes, will enable the creation of more advanced and reliable PCBs.

Frequently Asked Questions (FAQ)

-

Q: What is the difference between PCB fabrication and PCB assembly?

A: PCB fabrication is the process of manufacturing the bare printed circuit board, while PCB assembly involves soldering or mounting electronic components onto the fabricated board. -

Q: How long does the PCB assembly process typically take?

A: The lead time for PCB assembly varies depending on factors such as design complexity, production volume, and component availability. Generally, the process can take anywhere from a few days to several weeks. -

Q: Can I assemble PCBs in-house instead of outsourcing?

A: Yes, it is possible to assemble PCBs in-house, but it requires significant investment in equipment, facilities, and skilled labor. Outsourcing is often more cost-effective and allows for access to specialized expertise. -

Q: What is the minimum order quantity (MOQ) for PCB assembly?

A: The MOQ for PCB assembly varies among service providers. Some providers offer low-volume production services with MOQs as low as one piece, while others may require higher minimum quantities for cost-effectiveness. -

Q: How can I ensure the quality of my assembled PCBs?

A: To ensure the quality of your assembled PCBs, work with a reputable PCB assembly service provider that follows strict quality control measures, such as ISO certifications and advanced inspection and testing procedures. Clearly communicate your requirements and specifications, and consider conducting regular audits of the provider’s facilities and processes.

Conclusion

PCB assembly is a critical process in the manufacturing of electronic devices, directly impacting the functionality, reliability, and quality of the final product. Understanding the types of PCB assembly, the process involved, and the factors to consider when choosing a service provider is essential for ensuring successful project outcomes. By staying informed about industry trends and best practices, you can make informed decisions and optimize your PCB assembly strategy for long-term success.

No responses yet