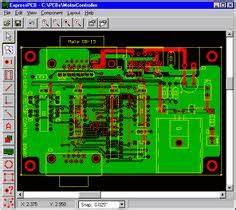

What is Express PCB?

Express PCB is a rapid printed circuit board (PCB) manufacturing and assembly service that allows customers to receive high-quality PCBs in a short turnaround time. This service caters to the needs of engineers, designers, and hobbyists who require quick prototyping or small-batch production of PCBs.

Benefits of Express PCB

- Fast turnaround times

- Cost-effective for small quantities

- High-quality PCBs

- Suitable for prototyping and testing

Key Considerations for Express PCB Manufacturing

When opting for Express PCB manufacturing, there are several crucial factors to keep in mind to ensure a smooth and successful process.

1. Design for Manufacturability (DFM)

One of the most important aspects of Express PCB manufacturing is ensuring that your PCB design is optimized for manufacturability. This involves adhering to the manufacturer’s design guidelines and considering factors such as:

- Minimum trace width and spacing

- Minimum drill hole size

- Copper weight and thickness

- Clearance and creepage distances

- Solder mask and silkscreen requirements

By following DFM principles, you can minimize the risk of manufacturing issues and delays, ultimately saving time and money.

2. Material Selection

Choosing the right materials for your Express PCB is crucial for its performance and reliability. The most common PCB materials include:

| Material | Description | Applications |

|---|---|---|

| FR-4 | Glass-reinforced epoxy laminate | General-purpose, high-volume production |

| Polyimide | High-temperature, flexible material | Aerospace, military, and medical devices |

| Aluminum | Metal-core PCB for heat dissipation | High-power LED lighting, automotive electronics |

| Rogers | High-frequency, low-loss material | RF and microwave applications |

Consider the electrical, thermal, and mechanical requirements of your application when selecting the appropriate material for your Express PCB.

3. Layer Stack-up

The layer stack-up of your Express PCB refers to the arrangement of copper layers, insulating layers, and planes within the board. A well-designed layer stack-up can help:

- Minimize crosstalk and electromagnetic interference (EMI)

- Improve signal integrity and power delivery

- Reduce manufacturing complexity and cost

Work closely with your Express PCB manufacturer to determine the optimal layer stack-up for your design, taking into account factors such as signal speed, impedance control, and power requirements.

Express PCB Assembly Considerations

Once your Express PCB is manufactured, the next step is to assemble the components onto the board. Here are some key considerations for Express PCB assembly:

1. Component Selection and Placement

Proper component selection and placement are essential for a successful Express PCB assembly. When choosing components, consider factors such as:

- Package type and size

- Electrical specifications

- Availability and lead time

- Cost and minimum order quantity

When placing components on the PCB, follow best practices such as:

- Grouping similar components together

- Providing adequate spacing for soldering and inspection

- Orienting components for easy assembly and testing

- Minimizing the number of different component types

2. Soldering Techniques

The choice of soldering technique can significantly impact the quality and reliability of your Express PCB assembly. The two main soldering methods are:

-

Through-hole soldering: Components with leads are inserted through holes in the PCB and soldered on the opposite side. This method is suitable for larger components and provides strong mechanical connections.

-

Surface-mount soldering: Components are placed directly on the surface of the PCB and soldered using techniques such as reflow or wave soldering. This method allows for smaller component sizes and higher component density.

Choose the appropriate soldering technique based on your component types, PCB design, and production volume.

3. Inspection and Testing

To ensure the quality and functionality of your Express PCB assembly, it is crucial to perform thorough inspection and testing. Common inspection methods include:

- Visual inspection: Checking for proper component placement, soldering quality, and any visible defects.

- Automated optical inspection (AOI): Using cameras and image processing software to detect assembly defects.

- X-ray inspection: Examining hidden solder joints and connections within the PCB.

Functional testing should also be conducted to verify that the assembled PCB performs as intended. This may involve:

- In-circuit testing (ICT): Verifying the presence and value of individual components using a bed-of-nails fixture.

- Functional testing: Applying input signals and measuring output responses to ensure proper operation.

- Boundary scan testing: Using built-in test circuitry to isolate and test individual components and interconnections.

By incorporating comprehensive inspection and testing procedures, you can identify and address any issues early in the production process, ultimately improving the quality and reliability of your Express PCB assembly.

FAQ

- What is the typical turnaround time for Express PCB manufacturing?

-

Express PCB manufacturing typically offers turnaround times ranging from 24 hours to 5 business days, depending on the complexity of the design and the manufacturer’s capabilities.

-

Can I get a prototype PCB made through Express PCB services?

-

Yes, Express PCB services are well-suited for prototyping and small-batch production. Many manufacturers offer low minimum order quantities and quick turnaround times for prototype PCBs.

-

What file formats are required for Express PCB manufacturing?

-

Most Express PCB manufacturers accept industry-standard file formats such as Gerber files (RS-274X), drill files (Excellon), and pick-and-place files (CSV or TXT). Some may also accept CAD design files from popular software such as Altium Designer, Eagle, or KiCad.

-

How much does Express PCB Manufacturing Cost?

-

The cost of Express PCB manufacturing varies depending on factors such as the PCB size, layer count, material, quantity, and turnaround time. Prices can range from a few dollars to several hundred dollars per PCB. Many manufacturers offer online quoting tools to help estimate costs based on your specific requirements.

-

Can I get assembled PCBs through Express PCB services?

- Yes, many Express PCB manufacturers offer turnkey assembly services, which include component sourcing, PCB assembly, and testing. This allows you to receive fully assembled and functional PCBs in a short turnaround time, saving you time and effort in the production process.

Conclusion

Express PCB manufacturing and assembly offer a fast and cost-effective solution for engineers, designers, and hobbyists who need quick prototyping or small-batch production of PCBs. By understanding the key considerations for PCB design, material selection, layer stack-up, component placement, soldering techniques, and inspection and testing, you can ensure a smooth and successful Express PCB manufacturing and assembly process. Working closely with your chosen Express PCB manufacturer and following their guidelines and best practices can help you achieve high-quality, reliable, and functional PCBs in a short turnaround time.

No responses yet