Introduction to PCB Design Flow

Printed Circuit Board (PCB) design is a complex process that involves several stages, from concept to manufacturing. To ensure the best possible outcome, it is crucial to follow an optimized PCB design flow. This article will guide you through the steps involved in an efficient and effective PCB design process.

The Importance of an Optimized PCB Design Flow

An optimized PCB design flow is essential for several reasons:

- It reduces the likelihood of errors and redesigns, saving time and money.

- It ensures that the final product meets the required specifications and performs as expected.

- It streamlines the communication between various stakeholders, such as designers, engineers, and manufacturers.

Stages of PCB Design Flow

The PCB design flow can be divided into several key stages, each with its own set of tasks and considerations.

1. Concept and Schematic Design

The first stage of the PCB design flow involves developing the concept and creating the schematic design. This stage includes the following steps:

- Define the project requirements and specifications.

- Create a block diagram of the system architecture.

- Select components based on the requirements and available space.

- Create a schematic diagram using EDA (Electronic design Automation) tools.

- Perform a design review to ensure the schematic meets the requirements.

Tips for Effective Schematic Design

- Use a hierarchical design approach to keep the schematic organized and easy to understand.

- Follow consistent naming conventions for components and nets.

- Use schematic symbols that accurately represent the physical components.

- Add notes and comments to clarify the design intent.

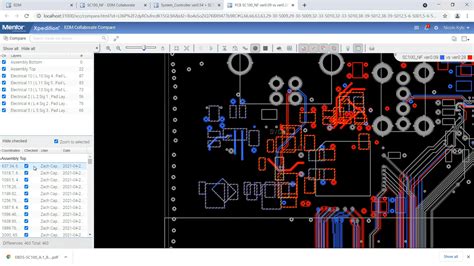

2. Component Placement

Once the schematic design is complete, the next stage is to place the components on the PCB Layout. This stage involves the following steps:

- Define the PCB Stack-Up and layer structure.

- Create a component footprint library.

- Place the components on the PCB layout, considering factors such as signal integrity, power distribution, and mechanical constraints.

- Define the component placement rules, such as minimum spacing and orientation.

- Perform a placement review to ensure the layout meets the requirements.

Tips for Optimal Component Placement

- Place critical components close to each other to minimize signal path lengths.

- Separate sensitive analog and digital circuits to avoid interference.

- Consider the mechanical aspects of the design, such as connector locations and mounting holes.

- Use a modular placement approach for complex designs, grouping related components together.

3. Routing and Signal Integrity

With the components placed, the next stage is to route the connections between them while ensuring signal integrity. This stage includes the following steps:

- Define the routing rules, such as trace width, spacing, and via size.

- Route the critical signals first, such as high-speed signals and power nets.

- Use appropriate routing techniques, such as differential pairs and controlled impedance traces, for high-speed signals.

- Perform signal integrity simulations to verify the design.

- Complete the routing for the remaining signals.

Tips for Effective Routing and Signal Integrity

- Use a gridded routing approach to ensure consistent trace spacing and minimize crosstalk.

- Avoid sharp corners and use curved traces to minimize signal reflections.

- Provide proper grounding and shielding for sensitive signals.

- Use ground planes and power planes to provide a low-impedance return path for signals.

4. Design Rule Check (DRC) and Layout Verification

Before finalizing the PCB layout, it is essential to perform a Design Rule Check (DRC) and layout verification. This stage involves the following steps:

- Set up the DRC rules based on the manufacturing constraints and design requirements.

- Run the DRC to identify any violations of the specified rules.

- Review and resolve any DRC errors or warnings.

- Perform a layout verification to ensure the design meets the functional and mechanical requirements.

- Generate a 3D model of the PCB to check for any mechanical interferences.

Tips for Effective DRC and Layout Verification

- Use a comprehensive set of DRC rules to catch potential issues early in the design process.

- Collaborate with the manufacturing team to ensure the DRC rules align with their capabilities.

- Perform a visual inspection of the layout to identify any potential issues not caught by the DRC.

- Use 3D modeling tools to verify the mechanical aspects of the design, such as component clearances and enclosure fit.

5. Manufacturing Preparation

Once the PCB layout is finalized, the next stage is to prepare the design files for manufacturing. This stage includes the following steps:

- Generate the Gerber Files for each layer of the PCB.

- Create the drill files for the vias and mounting holes.

- Generate the Bill of Materials (BOM) and assembly drawings.

- Provide the manufacturing files to the PCB Fabrication and assembly vendors.

- Communicate any special requirements or instructions to the manufacturing team.

Tips for Smooth Manufacturing Preparation

- Use a consistent naming convention for the Gerber and drill files.

- Verify the Gerber files using a Gerber viewer to ensure they are correct.

- Provide clear and concise assembly instructions, including component orientations and special handling requirements.

- Maintain open communication with the manufacturing team to address any questions or concerns.

PCB Design Flow Checklist

To ensure a successful PCB design flow, use the following checklist:

- Concept and Schematic Design

- [ ] Project requirements and specifications defined

- [ ] System architecture block diagram created

- [ ] Components selected

- [ ] Schematic diagram created using EDA tools

-

[ ] Design review performed

-

Component Placement

- [ ] PCB stack-up and layer structure defined

- [ ] Component footprint library created

- [ ] Components placed on the PCB layout

- [ ] Component placement rules defined

-

[ ] Placement review performed

-

Routing and Signal Integrity

- [ ] Routing rules defined

- [ ] Critical signals routed

- [ ] Appropriate routing techniques used for high-speed signals

- [ ] Signal integrity simulations performed

-

[ ] Remaining signals routed

-

Design Rule Check (DRC) and Layout Verification

- [ ] DRC rules set up based on manufacturing constraints and design requirements

- [ ] DRC run to identify violations

- [ ] DRC errors and warnings resolved

- [ ] Layout verification performed

-

[ ] 3D model generated to check for mechanical interferences

-

Manufacturing Preparation

- [ ] Gerber files generated for each PCB layer

- [ ] Drill files created for vias and mounting holes

- [ ] Bill of Materials (BOM) and assembly drawings generated

- [ ] Manufacturing files provided to PCB fabrication and assembly vendors

- [ ] Special requirements or instructions communicated to the manufacturing team

Common PCB Design Flow Challenges and Solutions

Designing a PCB can present various challenges, but with the right approach, these challenges can be overcome. Some common PCB design flow challenges and their solutions include:

1. Component Availability and Obsolescence

Challenge: Components may become obsolete or unavailable during the design process, leading to redesigns and delays.

Solution:

– Select components with long-term availability and multiple sourcing options.

– Monitor component availability and lifecycle status throughout the design process.

– Have alternative components identified in case of obsolescence or supply chain issues.

2. Signal Integrity and EMI/EMC

Challenge: Ensuring signal integrity and managing electromagnetic interference (EMI) and electromagnetic compatibility (EMC) can be difficult, especially in high-speed designs.

Solution:

– Follow best practices for high-speed PCB design, such as controlled impedance traces and proper termination.

– Use simulation tools to analyze signal integrity and identify potential issues early in the design process.

– Incorporate EMI/EMC mitigation techniques, such as proper grounding, shielding, and filtering.

3. Thermal Management

Challenge: Ensuring proper thermal management to prevent component overheating and reliability issues.

Solution:

– Perform thermal simulations to identify potential hot spots and optimize component placement.

– Use thermal management techniques, such as copper pours, thermal vias, and heatsinks, to dissipate heat effectively.

– Consider the use of thermal interface materials (TIMs) to improve heat transfer between components and the PCB.

4. Manufacturing and Assembly Constraints

Challenge: Designing a PCB that can be efficiently manufactured and assembled while meeting the required specifications.

Solution:

– Collaborate with the manufacturing and assembly teams to understand their capabilities and constraints.

– Follow the manufacturer’s design guidelines and incorporate their feedback into the design process.

– Use Design for Manufacturing (DFM) and Design for Assembly (DFA) principles to optimize the design for manufacturability and assembly.

5. Design Collaboration and Version Control

Challenge: Managing design collaboration and version control among multiple team members and stakeholders.

Solution:

– Use a version control system, such as Git, to manage design files and track changes.

– Establish clear communication channels and design review processes to ensure all stakeholders are aligned.

– Use collaborative design tools that allow multiple team members to work on the same design simultaneously.

PCB Design Flow Best Practices

To achieve an optimum PCB design flow, consider the following best practices:

- Start with a clear understanding of the project requirements and specifications.

- Use a modular design approach to break down complex designs into manageable sections.

- Follow consistent naming conventions and design standards throughout the project.

- Perform regular design reviews to catch potential issues early and ensure alignment among stakeholders.

- Use simulation tools to verify signal integrity, power integrity, and thermal performance.

- Collaborate closely with the manufacturing and assembly teams to ensure the design is optimized for manufacturability.

- Continuously monitor and update the design based on component availability and lifecycle status.

- Document the design process, including design decisions, trade-offs, and lessons learned.

Conclusion

An optimized PCB design flow is essential for creating high-quality, reliable, and manufacturable PCBs. By following the stages outlined in this article and adopting the best practices and solutions to common challenges, you can streamline your PCB design process and achieve better results.

Remember to prioritize clear communication, collaboration, and continuous improvement throughout the design flow. By doing so, you can ensure that your PCB design meets the required specifications, performs as expected, and can be efficiently manufactured and assembled.

Frequently Asked Questions (FAQ)

-

What is the importance of a well-defined PCB design flow?

A well-defined PCB design flow ensures that the design process is efficient, organized, and results in a high-quality, manufacturable PCB. It helps to minimize errors, reduce redesigns, and improve collaboration among team members. -

What are the key stages of a typical PCB design flow?

The key stages of a typical PCB design flow include: - Concept and schematic design

- Component placement

- Routing and signal integrity

- Design Rule Check (DRC) and layout verification

-

Manufacturing preparation

-

How can I ensure signal integrity in my PCB design?

To ensure signal integrity in your PCB design, follow these tips: - Use controlled impedance traces for high-speed signals

- Properly terminate transmission lines

- Minimize crosstalk by using appropriate trace spacing and routing techniques

- Use ground planes and power planes to provide a low-impedance return path

-

Perform signal integrity simulations to verify the design

-

What are some common challenges in PCB design, and how can they be overcome?

Some common PCB design challenges include component availability and obsolescence, signal integrity and EMI/EMC issues, thermal management, manufacturing and assembly constraints, and design collaboration and version control. These challenges can be overcome by selecting appropriate components, following best practices for high-speed design, performing simulations, collaborating with manufacturing teams, and using version control and collaborative design tools. -

What are some best practices for an optimum PCB design flow?

Some best practices for an optimum PCB design flow include: - Starting with clear project requirements and specifications

- Using a modular design approach

- Following consistent naming conventions and design standards

- Performing regular design reviews

- Using simulation tools to verify performance

- Collaborating closely with manufacturing and assembly teams

- Continuously monitoring and updating the design based on component availability

- Documenting the design process, decisions, and lessons learned

By following these best practices and addressing common challenges, you can optimize your PCB design flow and create high-quality, reliable, and manufacturable PCBs.

No responses yet