Introduction to RAYPCB PCB Assembly Services

RAYPCB is a leading provider of comprehensive PCB assembly services, catering to the diverse needs of electronics manufacturers worldwide. With state-of-the-art facilities, experienced engineers, and a commitment to quality, RAYPCB offers a one-stop solution for all your PCB assembly requirements. From prototype development to high-volume production, RAYPCB ensures that your projects are completed efficiently, cost-effectively, and to the highest industry standards.

The Advantages of Choosing RAYPCB for Your PCB Assembly Needs

1. Expertise and Experience

RAYPCB boasts a team of highly skilled engineers and technicians with extensive experience in PCB assembly. Our experts are well-versed in the latest technologies and best practices, ensuring that your projects are handled with the utmost professionalism and expertise. Whether you require simple or complex PCB assemblies, RAYPCB has the knowledge and resources to deliver exceptional results.

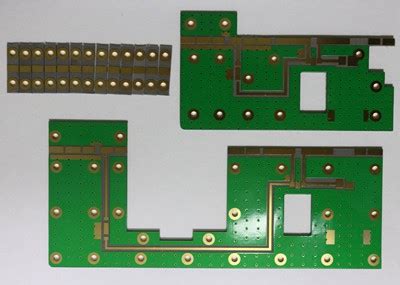

2. Advanced Manufacturing Facilities

Our state-of-the-art manufacturing facilities are equipped with the latest equipment and tools to handle a wide range of PCB assembly projects. From automated SMT Lines to precise manual assembly stations, RAYPCB invests in cutting-edge technology to ensure the highest levels of quality, consistency, and efficiency in our production processes.

3. Comprehensive Services

RAYPCB offers a comprehensive range of PCB assembly services to meet the unique needs of our clients. Our services include:

- Prototype development and low-volume production

- High-volume PCB assembly

- Surface mount technology (SMT) assembly

- Through-hole technology (THT) assembly

- Mixed technology assembly (SMT + THT)

- Box build assembly

- Functional testing and quality assurance

With RAYPCB as your partner, you can rely on a single source for all your PCB assembly requirements, streamlining your supply chain and reducing lead times.

4. Quality Assurance and Testing

At RAYPCB, quality is our top priority. We have implemented rigorous quality control measures throughout our manufacturing process to ensure that every PCB assembly meets or exceeds the highest industry standards. Our experienced quality assurance team conducts thorough inspections and testing at various stages of production, including:

- Incoming material inspection

- In-process quality control

- Automated optical inspection (AOI)

- X-ray inspection

- Functional testing

- Final quality control

By adhering to strict quality standards and utilizing advanced testing equipment, RAYPCB delivers consistently reliable and high-performing PCB assemblies.

5. Cost-Effective Solutions

RAYPCB understands the importance of cost-efficiency in today’s competitive market. We strive to offer our clients the most Cost-Effective PCB Assembly solutions without compromising on quality. Our streamlined processes, advanced technology, and strong supplier relationships enable us to optimize production costs and pass the savings on to our clients.

The RAYPCB PCB Assembly Process

1. Design and Engineering Support

RAYPCB’s experienced engineering team works closely with clients to provide design and engineering support. We review your PCB design files, offer recommendations for manufacturability, and assist in optimizing your design for cost-effectiveness and reliability. Our engineers use the latest CAD tools and design software to ensure that your PCB design is ready for production.

2. Prototype Development

For clients requiring prototype PCBs, RAYPCB offers quick-turn prototype services. We understand the importance of rapid prototyping in the product development cycle, and our dedicated prototype team works diligently to deliver high-quality prototypes in the shortest possible timeframe. Our prototype services include:

- Quick-turn PCB fabrication

- Prototype PCB assembly

- Functional testing and validation

- Design refinement and optimization

3. Component Sourcing and Procurement

RAYPCB has established strong relationships with leading component suppliers worldwide. Our experienced procurement team sources high-quality components at competitive prices, ensuring a reliable and cost-effective supply chain for your PCB assembly projects. We maintain a comprehensive component library and work closely with our clients to select the most suitable components for their specific requirements.

4. PCB Assembly

Once the components are sourced and the PCB design is finalized, RAYPCB begins the assembly process. Our state-of-the-art manufacturing facilities are equipped to handle a wide range of PCB assembly technologies, including:

- Surface Mount Technology (SMT) Assembly:

- Automated SMT lines for high-volume production

- Precise placement of small and large components

-

Advanced solder paste printing and reflow soldering

-

Through-Hole Technology (THT) Assembly:

- Manual and automated THT assembly stations

- Wave soldering and selective soldering capabilities

-

Skilled operators for precise component placement

-

Mixed Technology Assembly:

- Combination of SMT and THT assembly techniques

- Efficient integration of different component types

- Expertise in handling complex mixed-technology designs

5. Quality Control and Testing

Throughout the PCB assembly process, RAYPCB implements rigorous quality control measures to ensure the highest levels of quality and reliability. Our experienced quality assurance team conducts comprehensive inspections and testing, including:

- Automated Optical Inspection (AOI):

- High-speed, non-contact inspection of assembled PCBs

- Detection of component placement and soldering defects

-

Ensures consistent quality and minimizes human error

-

X-Ray Inspection:

- Non-destructive inspection of solder joints and internal components

- Identification of hidden defects, such as voids and bridging

-

Ensures the integrity of critical connections

-

Functional Testing:

- Comprehensive testing of assembled PCBs

- Verification of electrical functionality and performance

-

Customized test fixtures and software for specific requirements

-

Final Quality Control:

- Visual inspection and final functional testing

- Packaging and shipping preparation

- Ensures that finished products meet client specifications

6. Packaging and Shipping

Once the assembled PCBs have passed all quality control checks, RAYPCB carefully packages them to ensure safe transit to their final destination. We use high-quality packaging materials and follow industry-standard practices to protect your products during shipping. RAYPCB works with reliable shipping partners to deliver your PCB assemblies on time and in perfect condition.

Why Choose RAYPCB for Your PCB Assembly Needs?

Choosing the right PCB assembly partner is crucial for the success of your electronics manufacturing projects. RAYPCB offers a compelling combination of expertise, advanced facilities, comprehensive services, and a commitment to quality that sets us apart from the competition. By partnering with RAYPCB, you can expect:

- Reliable and high-quality PCB assembly services

- Experienced engineers and skilled technicians

- State-of-the-art manufacturing facilities and equipment

- Comprehensive services, from prototype to high-volume production

- Rigorous quality control and testing procedures

- Cost-effective solutions tailored to your specific needs

- Timely delivery and excellent customer support

RAYPCB is dedicated to building long-term partnerships with our clients, providing them with the support and expertise they need to succeed in the competitive electronics industry.

Frequently Asked Questions (FAQ)

- What is the minimum order quantity (MOQ) for PCB assembly at RAYPCB?

-

RAYPCB offers flexible MOQ options to accommodate the diverse needs of our clients. For prototype and low-volume production, we have no minimum order quantity requirements. For high-volume production, our MOQ varies depending on the specific project requirements. Please contact our sales team to discuss your specific needs.

-

How long does it take to complete a PCB assembly project at RAYPCB?

-

The lead time for PCB assembly projects depends on various factors, such as the complexity of the design, the availability of components, and the order quantity. For prototype and low-volume orders, RAYPCB offers quick-turn services with lead times as short as 24-48 hours. For high-volume production, lead times are typically longer and will be provided upon request.

-

What file formats does RAYPCB accept for PCB assembly projects?

-

RAYPCB accepts industry-standard file formats for PCB assembly, including Gerber files (RS-274X), ODB++ files, and CAD design files (such as Altium, Eagle, and KiCad). We also require the bill of materials (BOM) and assembly drawings to ensure accurate and efficient assembly.

-

Does RAYPCB offer design and engineering support for PCB assembly projects?

-

Yes, RAYPCB has a dedicated team of experienced engineers who provide design and engineering support to our clients. We can review your PCB design files, offer recommendations for manufacturability, and assist in optimizing your design for cost-effectiveness and reliability. Our engineering team uses the latest CAD tools and design software to ensure that your PCB design is ready for production.

-

What quality certifications does RAYPCB hold for PCB assembly?

- RAYPCB is committed to maintaining the highest quality standards in the industry. We hold several quality certifications, including ISO 9001:2015 for quality management systems, ISO 14001:2015 for environmental management systems, and IATF 16949:2016 for automotive quality management systems. These certifications demonstrate our dedication to providing consistently high-quality PCB assembly services to our clients.

Conclusion

RAYPCB is your trusted partner for one-stop PCB assembly services. With our expertise, advanced facilities, comprehensive services, and commitment to quality, we are well-equipped to handle all your electronics manufacturing needs. From prototype development to high-volume production, RAYPCB delivers reliable, cost-effective, and high-quality PCB assemblies that meet the most demanding industry standards.

By choosing RAYPCB for your PCB assembly requirements, you can streamline your supply chain, reduce lead times, and focus on your core business activities. Our experienced team is dedicated to providing exceptional service and support, ensuring that your projects are completed efficiently and to your satisfaction.

Contact RAYPCB today to discuss your PCB assembly needs and experience the benefits of partnering with a leading provider in the industry. Let us be your one-stop solution for all your electronics manufacturing requirements.

| Service | Description |

|---|---|

| Prototype Development | Quick-turn prototype services for rapid product development |

| Low-Volume Production | Flexible low-volume production options for small-scale projects |

| High-Volume Production | Efficient high-volume production capabilities for large-scale orders |

| SMT Assembly | Automated surface mount technology assembly for precision placement |

| THT Assembly | Through-hole technology assembly for reliable component mounting |

| Mixed Technology Assembly | Combination of SMT and THT assembly for complex designs |

| Quality Control | Rigorous quality control measures and testing procedures |

| Engineering Support | Experienced engineers providing design and manufacturability support |

No responses yet