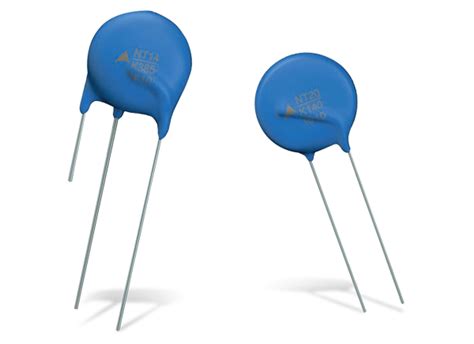

What are Varistors?

Varistors, short for variable resistors, are electronic components that exhibit non-linear current-voltage characteristics. They are designed to protect electronic circuits from voltage spikes and transient surges by limiting the voltage across their terminals. The most common type of varistor is the Metal Oxide Varistor (MOV), which is widely used in various applications, including power supplies, surge protectors, and telecommunications equipment.

How do MOVs work?

Metal Oxide Varistors are composed of a ceramic material, typically zinc oxide (ZnO), combined with other metal oxides such as bismuth, cobalt, and manganese. These metal oxides are mixed together, pressed into a disk shape, and sintered at high temperatures. The resulting material has a polycrystalline structure with numerous grain boundaries, which play a crucial role in the varistor’s functionality.

Under normal operating conditions, the MOV acts as a high-resistance component, allowing only a small leakage current to flow through it. However, when the voltage across the MOV exceeds a certain threshold, known as the varistor voltage, the grain boundaries break down, and the MOV becomes highly conductive. This allows the MOV to divert the excess current away from the protected circuit, effectively limiting the voltage across its terminals.

Key characteristics of MOVs

-

Varistor voltage (V1mA): The voltage at which the MOV starts to conduct a current of 1 mA. This is the voltage rating of the varistor and is chosen based on the application requirements.

-

Clamping voltage (Vc): The maximum voltage that appears across the MOV during a transient event. It is typically higher than the varistor voltage and depends on the magnitude and duration of the transient current.

-

Energy absorption capacity: The amount of energy the MOV can absorb during a transient event without being damaged. It is usually expressed in joules (J) and depends on the size and material composition of the varistor.

-

Response time: The time it takes for the MOV to switch from its high-resistance state to its low-resistance state when a transient occurs. MOVs have fast response times, typically in the range of nanoseconds.

Applications of MOVs

Metal Oxide Varistors find applications in various fields where protection against voltage transients and surges is essential. Some common applications include:

Power supply protection

MOVs are frequently used in power supplies to protect against voltage spikes caused by lightning strikes, switching transients, or other sources. They are connected in parallel with the input or output of the power supply to clamp the voltage to a safe level.

Surge protection devices (SPDs)

Surge protectors, also known as transient voltage surge suppressors (TVSS), employ MOVs as their main protective component. These devices are designed to safeguard electronic equipment from voltage surges that can occur on power lines, telephone lines, or data communication lines.

Telecommunications equipment

MOVs are used in telecommunications equipment, such as modems, routers, and switches, to protect against voltage surges on communication lines. They help ensure the reliability and longevity of the equipment by preventing damage caused by transient overvoltages.

Automotive electronics

In the automotive industry, MOVs are used to protect sensitive electronic components, such as engine control units (ECUs), from voltage transients caused by load dumps, alternator field decay, or other electrical disturbances in the vehicle’s electrical system.

Selecting the right MOV

When choosing an MOV for a specific application, several factors need to be considered:

-

Voltage rating: The varistor voltage should be selected based on the nominal operating voltage of the protected circuit. It should be higher than the maximum continuous operating voltage to avoid continuous conduction of the MOV.

-

Energy absorption capacity: The MOV should be capable of absorbing the expected energy of the transient events without being damaged. This is determined by the size and material composition of the varistor.

-

Clamping voltage: The clamping voltage should be low enough to protect the sensitive components in the circuit but high enough to avoid interfering with normal operation.

-

Response time: The response time of the MOV should be fast enough to effectively suppress the transient event before it can cause damage to the protected circuit.

MOV selection table

| Application | Voltage Rating | Energy Absorption Capacity | Clamping Voltage | Response Time |

|---|---|---|---|---|

| Power supply protection | 120 VAC – 480 VAC | 10 J – 100 J | 200 V – 1000 V | < 25 ns |

| Surge protection devices | 120 VAC – 480 VAC | 100 J – 1000 J | 200 V – 1000 V | < 25 ns |

| Telecommunications equipment | 5 V – 48 V | 0.1 J – 10 J | 10 V – 100 V | < 1 ns |

| Automotive electronics | 12 V – 48 V | 1 J – 10 J | 20 V – 100 V | < 1 ns |

MOV failure modes and protection

Although MOVs are designed to protect circuits from voltage transients, they can fail under certain conditions. The two main failure modes of MOVs are:

-

Thermal runaway: If the MOV is subjected to a prolonged overvoltage or a transient event that exceeds its energy absorption capacity, it can enter a state of thermal runaway. In this state, the MOV’s resistance decreases, leading to increased current flow and heat generation. This can result in the MOV short-circuiting and potentially causing damage to the protected circuit.

-

Gradual degradation: MOVs can degrade over time due to repeated exposure to transient events or continuous operation at high temperatures. This degradation manifests as a decrease in the varistor voltage and an increase in leakage current. As the MOV degrades, its ability to protect the circuit diminishes, and it may eventually fail.

To mitigate these failure modes and ensure the long-term reliability of the protected circuit, several measures can be taken:

-

Fusing: A fuse can be connected in series with the MOV to prevent excessive current flow in case of MOV failure. If the MOV enters thermal runaway and short-circuits, the fuse will blow, disconnecting the MOV from the circuit.

-

Thermal protection: A thermal fuse or a positive temperature coefficient (PTC) thermistor can be used in conjunction with the MOV to provide additional thermal protection. These components will interrupt the current flow if the MOV’s temperature rises above a certain threshold.

-

Proper sizing: Selecting an MOV with an appropriate voltage rating and energy absorption capacity for the specific application can help prevent overloading and premature failure of the varistor.

-

Regular maintenance: In critical applications, regular inspection and replacement of MOVs can help ensure that the protection remains effective over time. Monitoring the leakage current and varistor voltage can provide an indication of the MOV’s health and help predict when replacement is necessary.

Frequently Asked Questions (FAQ)

1. Can MOVs be used for AC and DC applications?

Yes, MOVs can be used for both AC and DC applications. However, the voltage rating of the MOV should be selected based on the type of voltage (AC or DC) and the expected transient levels in the specific application.

2. Are MOVs polarized?

No, MOVs are not polarized components. They can be connected in either direction in a circuit without affecting their performance.

3. Can MOVs be connected in series or parallel?

MOVs can be connected in parallel to increase the energy absorption capacity of the protection system. However, connecting MOVs in series is not recommended, as it can lead to uneven voltage distribution and reduced effectiveness of the protection.

4. How do MOVs compare to other surge protection devices?

MOVs offer fast response times and high energy absorption capabilities, making them suitable for many surge protection applications. However, they may not provide complete protection against all types of transient events. In some cases, additional protection devices, such as gas discharge tubes (GDTs) or transient voltage suppression (TVS) diodes, may be used in combination with MOVs to provide comprehensive protection.

5. Can MOVs be used for ESD protection?

While MOVs can provide some level of protection against electrostatic discharge (ESD), they are not the most suitable devices for this purpose. Tvs Diodes and multilayer varistors (MLVs) are more commonly used for ESD protection due to their faster response times and lower clamping voltages.

Conclusion

Metal Oxide Varistors are essential components in the field of circuit protection, offering a reliable and efficient means of safeguarding electronic devices and systems from voltage transients and surges. By understanding the key characteristics, applications, and selection criteria of MOVs, engineers and technicians can effectively incorporate these components into their designs, ensuring the long-term reliability and performance of the protected circuits.

However, it is crucial to be aware of the potential failure modes of MOVs and to implement appropriate protection measures, such as fusing and thermal protection, to mitigate these risks. Regular maintenance and monitoring of MOVs in critical applications can further enhance the overall reliability of the protection system.

As technology continues to advance and the demand for robust circuit protection grows, the role of Metal Oxide Varistors in various industries, including power electronics, telecommunications, and automotive, is expected to remain significant. By staying informed about the latest developments and best practices in MOV technology, engineers can continue to design and implement effective surge protection solutions that meet the evolving needs of modern electronic systems.

No responses yet