What is a Low-voltage cutoff Circuit?

A low-voltage cutoff circuit is an electronic circuit that monitors the voltage of a battery and disconnects the load when the voltage drops below a predetermined threshold. This prevents the battery from being drained beyond its safe operating range, which can lead to reduced capacity, shorter lifespan, and even complete failure.

Why is a Low-Voltage Cutoff Circuit Important?

Batteries have a minimum voltage level below which they should not be discharged. Discharging a battery below this level can cause irreversible chemical changes, resulting in reduced capacity and performance. In some cases, over-discharging can even cause the battery to leak or explode, posing a safety hazard.

A low-voltage cutoff circuit ensures that the battery is disconnected from the load before it reaches the critical discharge level. This protects the battery and extends its lifespan, while also preventing potential safety hazards.

Working Principle of a Low-Voltage Cutoff Circuit

A basic low-voltage cutoff circuit consists of the following components:

- Voltage reference: Provides a stable reference voltage to compare against the battery voltage.

- Comparator: Compares the battery voltage with the reference voltage and outputs a high or low signal based on the result.

- Switch: Disconnects the load from the battery when the comparator output goes low.

Here’s a simple block diagram illustrating the working principle of a low-voltage cutoff circuit:

┌───────────┐

│ Battery │

└─────┬─────┘

│

├───────────────┐

│ │

┌──────▼─────┐ ┌─────▼──────┐

│ Voltage │ │ Comparator │

│ Reference │ └─────┬──────┘

└────────────┘ │

│

┌─────▼──────┐

│ Switch │

└─────┬──────┘

│

│

┌─────▼──────┐

│ Load │

└────────────┘

When the battery voltage is above the reference voltage, the comparator output is high, and the switch remains closed, allowing current to flow to the load. When the battery voltage drops below the reference voltage, the comparator output goes low, opening the switch and disconnecting the load from the battery.

Designing a Low-Voltage Cutoff Circuit

To design a low-voltage cutoff circuit, you need to consider the following factors:

- Battery type and characteristics

- Minimum safe discharge voltage

- Load current requirements

- Hysteresis for stable operation

Selecting the Voltage Reference

The voltage reference determines the minimum voltage at which the cutoff circuit will disconnect the load. It should be chosen based on the minimum safe discharge voltage of the battery. For example, a lithium-ion battery typically has a minimum discharge voltage of 3.0V per cell.

Some common voltage reference ICs include:

| IC | Output Voltage | Tolerance |

|---|---|---|

| LM4040 | 2.5V, 4.1V | 0.1% |

| LT1004 | 1.2V, 2.5V | 0.4% |

| TL431 | Adjustable | 0.5% |

Choosing the Comparator

The comparator should have the following characteristics:

- Low quiescent current to minimize battery drain

- Rail-to-rail input and output for compatibility with low-voltage systems

- Hysteresis for stable operation

Some suitable comparators for low-voltage cutoff circuits include:

| IC | Quiescent Current | Input/Output | Hysteresis |

|---|---|---|---|

| LTC1440 | 0.3µA | Rail-to-rail | Adjustable |

| MAX9119 | 0.8µA | Rail-to-rail | Fixed |

| TS881 | 0.6µA | Rail-to-rail | None |

Selecting the Switch

The switch should be able to handle the maximum load current and have a low on-resistance to minimize voltage drop. MOSFETs are commonly used as switches in low-voltage cutoff circuits due to their low on-resistance and high current handling capability.

When selecting a MOSFET, consider the following parameters:

- Maximum drain current (ID)

- Maximum drain-source voltage (VDS)

- Threshold voltage (VGS(th))

- On-resistance (RDS(on))

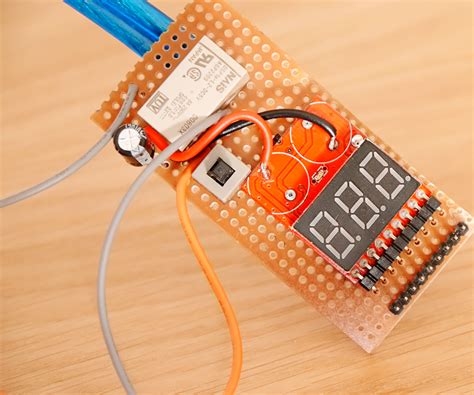

Implementing a Low-Voltage Cutoff Circuit

Now that we have covered the working principle and design considerations, let’s build a simple low-voltage cutoff circuit using the LTC1440 comparator and a P-channel MOSFET.

Circuit Diagram

┌───────────────────────────────────────────────────────┐

│ │

│ │

│ ┌───────┐ │

│ │ │ ┌────────────────────┐ │

┌─────┴───┐│ ┌┴┐ ┌───┤ LTC1440 │ ┌────────┴─────┐

│ Battery ││ │ │ │ │ │ │ P-MOSFET │

│ ││ │ │ │ │ ┌─────────┴───┤ │

│ ││ ┌┴─┴──┴───┤IN- │ │ │

│ ││ │ LM4040 ├──────────┤IN+ │ │

│ ││R1 │ 2.5V │ R3 │ │ │

│ │├────┐│ │ ┌──┐ │ ┌────┐ │ │

│ ││ ││ │ │ │ │ │ │D │S │

│ ││ ││ │ └┐ │ │ │R5 ├────┤ │

│ ││ ││ │ │_│ │ │ │ │ ┌─────────┴───────┐

│ ││ ││ │ │OUT└────┘G │ │ Load │

│ ││ ││ │ │ │ │ │

│ ││ │└─────────┴──────────┘ │ │ │

│ ││ │ R2 │ │ │

│ ││ │ │ │ │

└─────────┘│ └───────────────────────────────────┘ └────────────────┘

│

└──────────────────────────────────────────────

Component Values

- R1, R2: Voltage divider for setting the reference voltage. Choose values based on the desired cutoff voltage and the LM4040 reference voltage.

- R3: Hysteresis resistor. Adjust the value to set the desired hysteresis.

- R5: Pull-up resistor for the MOSFET gate. A typical value is 10kΩ.

- P-MOSFET: Choose a MOSFET with appropriate current and voltage ratings for your load.

Step-by-Step Guide

- Calculate the values for R1 and R2 based on the desired cutoff voltage and the LM4040 reference voltage.

- Select an appropriate value for R3 to set the desired hysteresis.

- Choose a suitable P-MOSFET based on the load current and voltage requirements.

- Assemble the circuit according to the diagram, using the calculated component values.

- Test the circuit by connecting a Variable Power Supply to the battery input and a load to the output. Gradually lower the input voltage and observe the cutoff behavior.

Frequently Asked Questions (FAQ)

-

Q: What happens if I don’t use a low-voltage cutoff circuit in my battery-powered device?

A: Without a low-voltage cutoff circuit, your battery may be discharged below its safe operating range, leading to reduced capacity, shorter lifespan, and potential safety hazards such as leakage or explosion. -

Q: Can I use a low-voltage cutoff circuit with any type of battery?

A: Low-voltage cutoff circuits can be used with various Battery Types, including lithium-ion, lithium-polymer, lead-acid, and NiMH. However, you need to adjust the cutoff voltage according to the specific battery chemistry and its minimum safe discharge voltage. -

Q: How do I set the cutoff voltage in a low-voltage cutoff circuit?

A: The cutoff voltage is determined by the voltage reference and the ratio of the voltage divider resistors (R1 and R2). By selecting appropriate values for these components, you can set the desired cutoff voltage. -

Q: What is hysteresis, and why is it important in a low-voltage cutoff circuit?

A: Hysteresis is the difference between the voltage at which the cutoff circuit disconnects the load and the voltage at which it reconnects the load. It prevents the circuit from rapidly switching on and off when the battery voltage is close to the cutoff threshold, ensuring stable operation. -

Q: Can I use a low-voltage cutoff circuit to protect my device from overcharging?

A: No, a low-voltage cutoff circuit is designed to protect the battery from over-discharging. To protect your device from overcharging, you need a separate overcharge protection circuit or a battery management system (BMS) that includes both overcharge and over-discharge protection.

Conclusion

A low-voltage cutoff circuit is a crucial component in battery-powered electronic devices, as it protects the battery from over-discharging and extends its lifespan. By understanding the working principle and design considerations, you can create a reliable and efficient low-voltage cutoff circuit for your projects.

Remember to choose appropriate components based on your specific battery and load requirements, and always test your circuit thoroughly before implementing it in your final device. With a properly designed low-voltage cutoff circuit, you can ensure the safety and longevity of your battery-powered projects.

No responses yet