Introduction to LCD interfaces

An LCD (Liquid Crystal Display) interface is a crucial component in many electronic devices, from smartphones and laptops to industrial control panels and medical equipment. LCD interfaces provide a visual means of displaying information, allowing users to interact with the device and access its functions. In this ultimate guide, we will delve into the world of LCD interfaces, exploring their history, types, working principles, and applications.

History of LCD technology

The development of LCD technology can be traced back to the late 19th century when Austrian botanist Friedrich Reinitzer discovered the liquid crystalline nature of cholesterol extracted from carrots. However, it wasn’t until the 1960s that the first practical application of liquid crystals was demonstrated by RCA researcher George Heilmeier. In 1968, RCA introduced the first LCD-based electronic display, paving the way for the widespread adoption of LCD technology.

Timeline of LCD technology development

| Year | Milestone |

|---|---|

| 1888 | Friedrich Reinitzer discovers liquid crystals |

| 1968 | RCA introduces the first LCD-based electronic display |

| 1971 | Hoffmann-La Roche introduces the twisted nematic (TN) field effect in LCDs |

| 1972 | Westinghouse Electric Corporation creates the first active-matrix LCD panel |

| 1982 | Seiko introduces the first LCD television |

| 1988 | Sharp Corporation introduces the first 14-inch color TFT LCD |

| 2007 | LCD televisions surpass CRT televisions in worldwide sales |

Types of LCD interfaces

There are several types of LCD interfaces, each with its own unique characteristics and applications. The most common types include:

TN (Twisted Nematic) LCD

TN LCDs are the most basic and inexpensive type of LCD interface. They offer fast response times but have limited viewing angles and color reproduction.

IPS (In-Plane Switching) LCD

IPS LCDs provide wider viewing angles and better color reproduction compared to TN LCDs, making them suitable for high-end displays and color-critical applications.

VA (Vertical Alignment) LCD

VA LCDs offer high contrast ratios and deep blacks, making them ideal for displaying high-quality images and videos. However, they have slower response times compared to TN and IPS LCDs.

OLED (Organic Light-Emitting Diode)

While not technically an LCD, OLED displays are often used as an alternative to traditional LCD interfaces. OLED displays offer superior image quality, wide viewing angles, and fast response times, but are more expensive to manufacture.

Working principles of LCD interfaces

LCD interfaces rely on the unique properties of liquid crystals to manipulate light and create visible images. The basic structure of an LCD consists of two polarized glass panels with a liquid crystal layer sandwiched between them. When an electric current is applied to the liquid crystal layer, the orientation of the crystals changes, allowing light to pass through or be blocked, creating the desired image.

Polarization and liquid crystals

Polarization plays a crucial role in the functioning of LCD interfaces. The two glass panels in an LCD are coated with polarizing filters, which only allow light waves oscillating in a specific direction to pass through. The liquid crystal layer between the glass panels can rotate the polarization of light depending on the applied voltage, effectively controlling the amount of light that passes through the display.

Backlight and color filters

To create a visible image, LCD interfaces require a backlight that shines through the liquid crystal layer. The backlight is typically a cold cathode fluorescent lamp (CCFL) or an array of light-emitting diodes (LEDs). Color LCD interfaces also incorporate color filters (red, green, and blue) to produce a wide range of colors by combining different intensities of the filtered light.

LCD interface connectivity

LCD interfaces can be connected to various devices using different connection methods, depending on the application and the required data transfer rate. Some common connectivity options include:

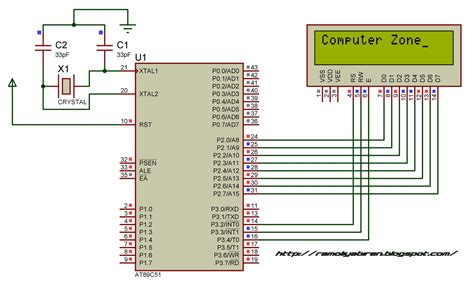

Parallel interface

Parallel interfaces, such as RGB and LVDS (Low-Voltage Differential Signaling), transmit data simultaneously over multiple lines, allowing for high data transfer rates. However, they require more pins and are more susceptible to electromagnetic interference.

Serial interface

Serial interfaces, such as SPI (Serial Peripheral Interface) and I2C (Inter-Integrated Circuit), transmit data sequentially over a single line, reducing the number of required pins. However, they have lower data transfer rates compared to parallel interfaces.

HDMI and DisplayPort

HDMI (High-Definition Multimedia Interface) and DisplayPort are digital interfaces commonly used in consumer electronics to connect LCD displays to video sources, such as computers, gaming consoles, and media players. They support high-resolution video and audio transmission over a single cable.

LCD interface controllers

LCD interface controllers are essential components that manage the communication between the host system and the LCD display. They handle tasks such as receiving display data, generating timing signals, and driving the LCD panel. Some popular LCD interface controllers include:

Intel HD Graphics

Intel HD Graphics is an integrated graphics controller found in many Intel processors, providing a cost-effective solution for driving LCD displays in laptops and desktop computers.

NVIDIA GPU

NVIDIA GPUs (Graphics Processing Units) are high-performance graphics controllers used in gaming and professional applications, offering advanced features such as hardware acceleration and support for multiple displays.

Raspberry Pi

The Raspberry Pi is a popular single-board computer that includes an integrated LCD interface controller, making it suitable for DIY projects and embedded applications.

Applications of LCD interfaces

LCD interfaces find applications in a wide range of industries and devices, including:

Consumer electronics

- Smartphones and tablets

- Laptops and desktop monitors

- Televisions and digital signage

Automotive industry

- In-vehicle infotainment systems

- Instrument clusters and head-up displays

- Rear-view mirrors with integrated displays

Medical devices

- Patient monitors and diagnostic equipment

- Medical imaging systems (e.g., ultrasound, X-ray)

- Wearable health monitoring devices

Industrial control systems

- Human-machine interfaces (HMIs)

- Process control panels

- Factory automation displays

Advantages and disadvantages of LCD interfaces

Advantages

- Low power consumption compared to CRT displays

- Compact and lightweight design

- Wide range of sizes and resolutions available

- Long lifespan and high reliability

- Relatively affordable production costs

Disadvantages

- Limited viewing angles compared to OLED displays

- Backlight bleeding and inconsistent illumination

- Slower response times compared to CRT and OLED displays

- Susceptible to image retention and dead pixels

- Color accuracy and contrast ratio may not match OLED displays

Future trends in LCD interface technology

As display technology continues to advance, LCD interfaces are evolving to meet the growing demands for higher resolution, better color accuracy, and improved energy efficiency. Some notable trends in LCD interface technology include:

Ultra-high resolution displays

The development of 8K and higher resolution LCD panels will provide users with incredibly detailed and lifelike images, enhancing the visual experience in applications such as gaming, entertainment, and professional content creation.

Mini-LED and Micro-LED backlighting

Mini-LED and Micro-LED backlighting technologies offer improved local dimming capabilities, higher contrast ratios, and wider color gamuts compared to traditional LED backlighting, bringing LCD interfaces closer to the performance of OLED displays.

Energy-efficient solutions

Manufacturers are focusing on developing more energy-efficient LCD interfaces by optimizing backlight systems, implementing advanced power management techniques, and exploring new materials and technologies that reduce power consumption.

Frequently Asked Questions (FAQ)

1. What is the difference between LCD and LED displays?

LCD (Liquid Crystal Display) and LED (Light-Emitting Diode) displays are often used interchangeably, but there is a difference between the two. LCD displays use a backlight (which can be LED or CCFL) to illuminate the liquid crystal layer, while LED displays use an array of LEDs as the light source itself. In general, LED displays offer better brightness, contrast, and energy efficiency compared to LCD displays.

2. Can LCD interfaces be used in touchscreen applications?

Yes, LCD interfaces can be combined with touchscreen technologies, such as resistive and capacitive Touch Sensors, to create interactive displays. Touchscreen LCDs are widely used in smartphones, tablets, and industrial control panels, allowing users to directly interact with the displayed content.

3. What is the typical lifespan of an LCD interface?

The lifespan of an LCD interface depends on various factors, such as the quality of the components, the usage conditions, and the backlight technology employed. On average, LCD interfaces can last between 30,000 and 60,000 hours of continuous use, which translates to several years of operation in most applications. However, factors like heat, humidity, and exposure to direct sunlight can shorten the lifespan of an LCD interface.

4. How do I choose the right LCD interface for my application?

When selecting an LCD interface for your application, consider factors such as the required display size, resolution, viewing angles, color accuracy, and response time. Also, take into account the environmental conditions in which the display will be used, such as temperature range, humidity, and exposure to dust or vibrations. Consult with LCD interface manufacturers or distributors to find the best solution for your specific needs.

5. Are LCD interfaces environmentally friendly?

LCD interfaces are generally considered more environmentally friendly than CRT displays, as they consume less power and contain fewer harmful substances. However, LCD interfaces still contain some toxic materials, such as mercury in CCFL backlights, which can pose environmental risks if not disposed of properly. Manufacturers are working on developing more sustainable LCD technologies, such as mercury-free backlights and recyclable materials, to minimize the environmental impact of LCD interfaces.

Conclusion

LCD interfaces have revolutionized the way we interact with electronic devices, providing a versatile and cost-effective solution for displaying information and graphics. From their early beginnings in the 1960s to the advanced technologies used today, LCD interfaces continue to evolve and adapt to the changing needs of various industries and applications.

By understanding the working principles, types, and connectivity options of LCD interfaces, as well as their advantages and disadvantages, you can make informed decisions when selecting and integrating LCD displays into your projects. As display technology continues to advance, LCD interfaces are poised to play a crucial role in shaping the future of visual communication and human-machine interaction.

So embrace the power of LCD interfaces, and unlock the potential of visual data representation in your applications. With the knowledge gained from this ultimate guide, you are well-equipped to navigate the world of LCD interfaces and create engaging, informative, and visually stunning displays.

No responses yet