What is a Laser Cutter?

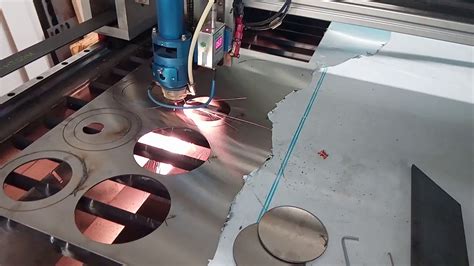

A laser cutter is a CNC machine that uses a high-powered laser beam to cut, mark, or engrave materials. The laser beam is focused through a lens and directed onto the material’s surface, where it melts, vaporizes, or burns the material, creating the desired shape or design. Laser cutters are controlled by computer software that interprets digital designs and translates them into machine instructions, enabling precise and repeatable results.

Types of Lasers Used in Laser Cutters

There are three main types of lasers used in laser cutters:

-

CO2 Lasers: These are the most common type of lasers used in laser cutters. They are suitable for cutting and engraving non-metallic materials such as wood, acrylic, fabric, and paper.

-

Fiber Lasers: These lasers are more powerful and efficient than CO2 lasers and are primarily used for marking and engraving metal surfaces.

-

UV Lasers: These lasers have a shorter wavelength and are used for high-precision cutting and marking of materials such as glass, ceramic, and some plastics.

Advantages of Using Laser Cutters

Laser cutters offer several advantages over traditional cutting and engraving methods:

-

Precision: Laser cutters can produce highly accurate and intricate designs with tight tolerances, making them ideal for applications that require precision and consistency.

-

Speed: Laser cutters can complete cutting and engraving tasks much faster than manual methods, reducing production time and increasing efficiency.

-

Versatility: Laser cutters can work with a wide range of materials, from wood and acrylic to metal and fabric, making them suitable for various applications and industries.

-

Cost-effectiveness: Laser cutters can reduce material waste and labor costs, as they require minimal setup time and can produce consistent results with fewer errors.

-

Customization: Laser cutters allow for easy customization of designs and patterns, enabling businesses to create unique and personalized products.

Applications of Laser Cutters

Laser cutters have found applications in numerous industries, from manufacturing and engineering to art and crafts. Some of the most common applications include:

Manufacturing and Engineering

-

Prototyping: Laser cutters are widely used in product development to create prototypes and test designs before mass production.

-

Fabrication: Laser cutters can be used to cut and shape various materials, such as metal sheets, plastic parts, and wooden components, for use in manufacturing and engineering projects.

-

Marking and Engraving: Laser cutters are used to mark and engrave serial numbers, barcodes, and logos on products for identification and branding purposes.

Art and Crafts

-

Jewelry Making: Laser cutters can create intricate and delicate designs on materials like wood, acrylic, and metal for unique and personalized jewelry pieces.

-

Home Decor: Laser cutters can be used to create custom wall art, signs, and decorative items for homes and businesses.

-

Fashion and Textiles: Laser cutters can cut and engrave fabric and leather to create unique patterns and designs for clothing, accessories, and footwear.

Education and Research

-

STEM Education: Laser cutters are used in schools and universities to teach students about CNC technology, design, and manufacturing processes.

-

Research and Development: Laser cutters are used in research laboratories to create custom components and devices for scientific experiments and studies.

Other Industries

-

Automotive: Laser cutters are used to cut and engrave interior and exterior components for vehicles, such as dashboard panels, trim pieces, and logos.

-

Medical: Laser cutters can create precise and sterile components for medical devices and equipment, such as implants and surgical tools.

-

Advertising and Signage: Laser cutters can create custom signs, displays, and promotional materials for businesses and events.

Choosing the Right Laser Cutter

When selecting a laser cutter for your specific application, consider the following factors:

-

Material Compatibility: Ensure that the laser cutter is compatible with the materials you plan to work with, as different lasers are suitable for different substrates.

-

Bed Size: Consider the size of the laser cutter’s bed, which determines the maximum dimensions of the materials you can cut or engrave.

-

Power and Speed: Choose a laser cutter with the appropriate power and speed settings for your application, as higher power and speed can result in faster production times but may also affect the quality of the output.

-

Software Compatibility: Ensure that the laser cutter is compatible with the design software you use, such as Adobe Illustrator, CorelDRAW, or AutoCAD.

-

Budget: Laser cutters vary in price depending on their features, size, and capabilities. Determine your budget and choose a machine that offers the best value for your specific needs.

Safety Considerations

Laser cutters are powerful machines that require proper safety measures to prevent accidents and injuries. Some important safety considerations include:

-

Proper Training: Ensure that all operators are properly trained in the safe use and maintenance of the laser cutter.

-

Personal Protective Equipment (PPE): Wear appropriate PPE, such as safety glasses, gloves, and respirators, when operating the laser cutter to protect against laser radiation, fumes, and debris.

-

Ventilation: Ensure that the laser cutter is operated in a well-ventilated area to prevent the buildup of harmful fumes and gases.

-

Fire Safety: Keep flammable materials away from the laser cutter and ensure that a fire extinguisher is readily available in case of a fire.

-

Regular Maintenance: Perform regular maintenance on the laser cutter to ensure that it is functioning correctly and safely, and to prevent malfunctions that could lead to accidents.

Future of Laser Cutting Technology

As technology advances, laser cutting is expected to become even more precise, efficient, and versatile. Some of the trends and developments in laser cutting technology include:

-

Automation and Integration: Laser cutters are increasingly being integrated with other manufacturing processes, such as 3D printing and robotics, to create fully automated production lines.

-

Fiber Laser Adoption: Fiber lasers are becoming more popular due to their higher efficiency, lower maintenance costs, and ability to cut and engrave a wider range of materials.

-

Increased Precision: Advances in laser technology and motion control systems are enabling laser cutters to achieve even higher levels of precision and accuracy.

-

Sustainable Manufacturing: Laser cutting technology is being used to develop more sustainable manufacturing processes, such as reducing material waste and energy consumption.

Frequently Asked Questions (FAQ)

-

What materials can a laser cutter work with?

Laser cutters can work with a wide range of materials, including wood, acrylic, plastic, metal, fabric, leather, paper, and more. However, the specific materials that a laser cutter can process depend on the type of laser being used (CO2, fiber, or UV). -

How much does a laser cutter cost?

The cost of a laser cutter varies depending on its size, features, and capabilities. Entry-level laser cutters can cost around $2,000 to $5,000, while high-end industrial machines can cost upwards of $100,000 or more. -

Can a laser cutter engrave photos?

Yes, laser cutters can engrave photos onto various materials, such as wood, acrylic, and metal. The photo must be converted into a grayscale or black-and-white image and processed using the appropriate software before it can be engraved. -

How long does it take to learn how to use a laser cutter?

The time it takes to learn how to use a laser cutter depends on the individual’s background and experience with similar technologies. Basic operation can be learned in a few hours, but becoming proficient in design and material optimization may take several weeks or months of practice. -

What maintenance is required for a laser cutter?

Regular maintenance for a laser cutter includes cleaning the lenses and mirrors, replacing the air filters, and checking the alignment of the laser beam. The specific maintenance requirements may vary depending on the manufacturer and model of the laser cutter.

| Application | Materials | Industries |

|---|---|---|

| Cutting | Wood, Acrylic, Plastic, Metal, Fabric, Leather | Manufacturing, Engineering, Art, Fashion |

| Engraving | Wood, Acrylic, Metal, Glass, Stone | Jewelry, Signage, Awards, Personalization |

| Marking | Metal, Plastic, Glass, Ceramic | Automotive, Medical, Electronics |

| Prototyping and Fabrication | Wood, Acrylic, Plastic, Metal | Product Development, Research, Education |

In conclusion, laser cutters are incredibly versatile CNC machines that have transformed the way we cut, mark, and engrave various materials. With their precision, speed, and cost-effectiveness, laser cutters have found applications in numerous industries, from manufacturing and engineering to art and crafts. As technology continues to advance, we can expect laser cutting to become even more precise, efficient, and sustainable, opening up new possibilities for innovation and creativity.

No responses yet