Introduction to Kelvin Connection

Kelvin connection, also known as four-terminal sensing or four-wire sensing, is a widely used technique in electrical measurements to accurately determine the resistance of a device under test (DUT). This method is particularly useful when measuring low resistances or when the resistance of the connecting wires is significant compared to the resistance of the DUT. In this beginner’s guide, we will explore the concept of Kelvin connection, its advantages, and its applications in various fields.

What is Kelvin Connection?

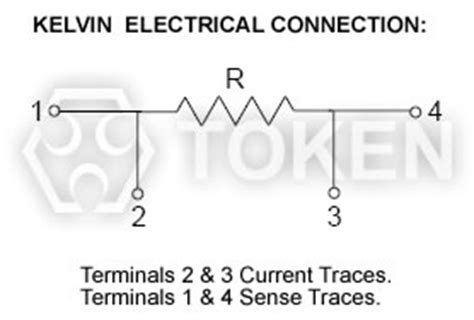

Kelvin connection is a measurement technique that uses four wires to connect the measuring instrument to the DUT. Two of the wires, known as the current-carrying or force wires, supply the current to the DUT, while the other two wires, called the voltage-sensing or sense wires, measure the voltage drop across the DUT. By separating the current-carrying and voltage-sensing paths, the Kelvin connection eliminates the voltage drop across the connecting wires, resulting in a more accurate resistance measurement.

Why Use Kelvin Connection?

The primary reason for using Kelvin connection is to obtain accurate resistance measurements, especially when dealing with low resistances or when the connecting wires have a significant resistance compared to the DUT. In a traditional two-wire measurement, the resistance of the connecting wires is included in the measured resistance, leading to inaccurate results. Kelvin connection overcomes this issue by measuring the voltage drop directly across the DUT, effectively canceling out the voltage drop across the connecting wires.

Advantages of Kelvin Connection

- Accurate measurement of low resistances

- Elimination of lead wire resistance effects

- Reduced measurement errors due to temperature variations

- Suitable for measuring resistances in harsh environments

- Enables precise measurement of contact resistances

How Kelvin Connection Works

The Four-Wire Configuration

In a Kelvin connection setup, four wires are used to connect the measuring instrument to the DUT. The four wires are typically color-coded for easy identification:

| Wire Color | Function |

|---|---|

| Red | Current-carrying (force) wire |

| Black | Current-carrying (force) wire |

| White | Voltage-sensing (sense) wire |

| Blue | Voltage-sensing (sense) wire |

The current-carrying wires are connected to the current source of the measuring instrument and the DUT, while the voltage-sensing wires are connected to the voltage-measuring circuitry of the instrument and the DUT.

Current Flow and Voltage Measurement

When a current is applied through the current-carrying wires, it flows through the DUT and creates a voltage drop across it. The voltage-sensing wires, which are connected as close as possible to the DUT, measure this voltage drop. Since the voltage-sensing wires carry minimal current, the voltage drop across them is negligible, and the measured voltage represents the true voltage drop across the DUT.

Calculating the Resistance

The resistance of the DUT is calculated using Ohm’s law:

R = V / I

Where:

– R is the resistance of the DUT

– V is the voltage measured by the voltage-sensing wires

– I is the current applied through the current-carrying wires

By using the Kelvin connection, the voltage drop across the connecting wires is eliminated from the measurement, resulting in an accurate determination of the DUT’s resistance.

Applications of Kelvin Connection

Kelvin connection finds applications in various fields where accurate resistance measurements are crucial. Some of these applications include:

Battery Testing and Monitoring

Kelvin connection is widely used in battery testing and monitoring applications, particularly in the automotive and aerospace industries. By accurately measuring the internal resistance of battery cells, engineers can assess the health and performance of the battery pack, detect potential issues, and optimize battery management systems.

High-Current Resistance Measurements

In applications involving high currents, such as power electronics, welding, and electric vehicle charging, Kelvin connection is essential for accurate resistance measurements. The high currents can cause significant voltage drops across the connecting wires, which would lead to inaccurate results if a traditional two-wire measurement were used.

Precision Resistor Characterization

Kelvin connection is used in the characterization and calibration of precision resistors, such as standard resistors and shunt resistors. These resistors are often used as references in calibration laboratories and require highly accurate resistance measurements to ensure their performance and reliability.

Contact Resistance Measurements

Kelvin connection is employed in the measurement of contact resistances, such as the resistance between a connector and a wire or between two conductors. Accurate contact resistance measurements are essential in ensuring the reliability and performance of electrical connections in various applications, including telecommunications, automotive systems, and industrial equipment.

Implementing Kelvin Connection

Equipment and Setup

To implement Kelvin connection, you will need the following equipment:

- A measuring instrument capable of four-wire measurements (e.g., a digital multimeter or a resistance meter)

- Four connecting wires (typically color-coded)

- Kelvin clips or probes for connecting the wires to the DUT

When setting up the Kelvin connection, ensure that:

- The current-carrying and voltage-sensing wires are connected as close as possible to the DUT to minimize the effects of lead resistance.

- The voltage-sensing wires are connected inside the current-carrying wire connection points to avoid including the contact resistance in the measurement.

- The connecting wires are properly secured and insulated to prevent short circuits and electrical noise.

Best Practices and Tips

To obtain the most accurate resistance measurements using Kelvin connection, consider the following best practices and tips:

- Use high-quality, low-resistance connecting wires to minimize the lead resistance effects.

- Ensure that the connecting wires are properly twisted to reduce electromagnetic interference and noise.

- Use shielded cables in noisy environments to minimize the impact of external electromagnetic fields.

- Avoid moving the connecting wires during the measurement to prevent changes in lead resistance.

- Allow sufficient settling time for the measurement to stabilize, especially when measuring low resistances or using long connecting wires.

Troubleshooting and Common Issues

Despite its advantages, Kelvin connection is not immune to issues that can affect the accuracy of the resistance measurement. Some common issues and their solutions include:

High Resistance Measurements

If the measured resistance is unexpectedly high, possible causes include:

- Poor contact between the connecting wires and the DUT

- Damaged or corroded connecting wires or probes

- Incorrect wire connections

To resolve these issues, ensure that the connections are secure and clean, replace any damaged components, and double-check the wire connections.

Noisy or Unstable Measurements

If the resistance measurements are noisy or unstable, possible causes include:

- Electromagnetic interference from nearby equipment

- Loose or intermittent connections

- Insufficient settling time

To mitigate these issues, use shielded cables, ensure that all connections are tight and secure, and allow adequate time for the measurement to stabilize.

Frequently Asked Questions (FAQ)

- What is the difference between Kelvin connection and two-wire measurement?

-

Kelvin connection uses four wires (two for current and two for voltage sensing) to eliminate the lead resistance effects, while two-wire measurement uses only two wires and includes the lead resistance in the measurement.

-

Can I use Kelvin connection to measure high resistances?

-

While Kelvin connection is primarily used for measuring low resistances, it can also be used for measuring high resistances. However, the benefits of using Kelvin connection diminish as the resistance of the DUT increases relative to the lead resistance.

-

How do I choose the appropriate connecting wires for Kelvin connection?

-

When selecting connecting wires for Kelvin connection, consider factors such as the wire gauge, insulation material, and flexibility. Use high-quality, low-resistance wires with good insulation properties to minimize lead resistance effects and electrical noise.

-

Can I use Kelvin connection with any measuring instrument?

-

To use Kelvin connection, the measuring instrument must support four-wire measurements. Most modern digital multimeters and resistance meters have this capability, but it is essential to consult the instrument’s specifications or user manual to confirm compatibility.

-

How do I properly maintain and store Kelvin connection equipment?

- To ensure the longevity and performance of Kelvin connection equipment, store the components in a clean, dry, and secure environment. Regularly inspect the connecting wires and probes for signs of damage or wear, and replace them as needed. Clean the connections with isopropyl alcohol to remove any dirt or oxidation buildup.

Conclusion

Kelvin connection is a powerful technique for accurately measuring low resistances and eliminating the effects of lead resistance in electrical measurements. By using four wires to separate the current-carrying and voltage-sensing paths, Kelvin connection enables precise resistance measurements in various applications, including battery testing, high-current systems, precision resistor characterization, and contact resistance measurements.

To successfully implement Kelvin connection, it is essential to use high-quality equipment, follow best practices for setup and measurement, and be aware of common issues and their solutions. By understanding the principles and applications of Kelvin connection, beginners can confidently employ this technique to obtain accurate and reliable resistance measurements in their projects and experiments.

No responses yet