Why Use Unusual PCB Shapes?

Before we dive into the how-to, let’s discuss some of the reasons you might want to use an unusual PCB shape:

Aesthetics and Branding

An unconventional PCB shape can make your product stand out from the crowd. A sleek, stylized shape signals that your device is unique, high-end, and thoughtfully designed. If you sell your product, an eye-catching PCB can be a key part of your branding.

Space Efficiency

In some cases, using a non-rectangle PCB can allow you to pack circuitry into tight or awkwardly-shaped enclosures. Curved or rounded PCBs are ideal for wearables, cylindrical devices, and other compact products where every millimeter matters.

Enhanced Functionality

The shape of your PCB can also enhance its functionality. For example, a circular PCB might provide better angular coverage for an array of sensors. A PCB with a hole or cutout could allow wires, buttons, or other components to protrude through.

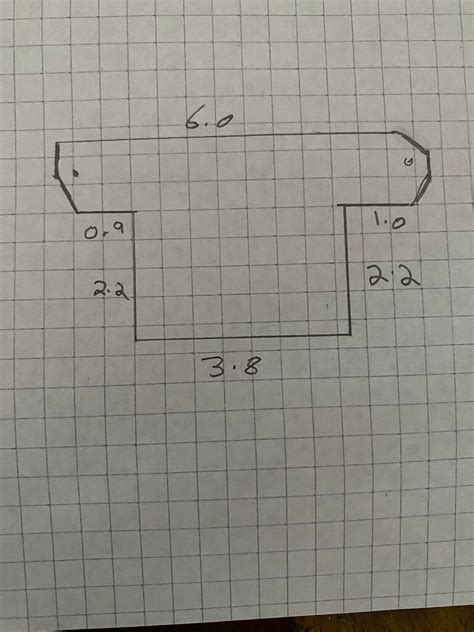

Design Considerations for Unusual PCB Shapes

Creating a non-standard PCB shape involves some unique design challenges and considerations compared to a typical rectangular board. Here are some of the key factors to keep in mind:

Structural Integrity

An unusual PCB shape with thin areas or cutouts may be less structurally sound than a solid rectangle. You’ll need to carefully consider how to provide mechanical support and prevent the PCB from flexing or snapping. Using a thicker PCB, additional mounting holes, or supportive overlays can help.

Component Placement

Fitting all your required components onto an unconventional PCB shape can be like playing Tetris. You may need to get creative with component placement and orientation. Use your PCB design software to visualize component clearances and check for conflicts.

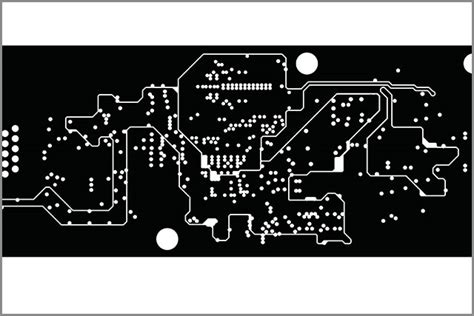

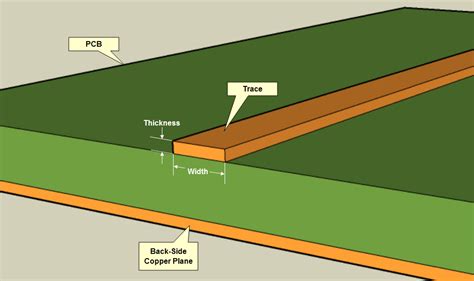

Trace Routing

Routing traces on a non-rectangular PCB can also be trickier than on a standard board. You may encounter bottlenecks or awkward angles. Give yourself ample time for routing and be prepared to do some manual trace cleanup.

Manufacturability

Not all PCB shapes can be easily manufactured. Extremely thin areas, sharp inside corners, and tricky cutouts can pose challenges. Consult with your PCB manufacturer early in the design process to ensure your shape is feasible and cost-effective to produce.

How to Design a 3D Donut PCB

Now let’s go through the steps to design a 3D donut or torus-shaped PCB using your preferred PCB design software:

-

Create the donut outline: Use the drawing tools to create two concentric circles representing the inner and outer diameters of your donut. The ring between these circles will be your PCB.

-

Add mounting holes: Place mounting holes at regular intervals around the donut. These holes will allow you to secure the layers of the donut together.

-

Place components: Arrange your components on the donut as you would for a normal PCB. Keep the component height in mind, as this will determine the thickness needed for each donut layer.

-

Route traces: Carefully route the connections between your components. You may need to route some traces on an inner layer of the donut.

-

Create the 3D stack-up: Determine how many PCB layers you need to accommodate your components and routing. Design a stack-up with your donut outline repeated on each layer, adjusting the inner and outer diameters as needed to create a tiered effect.

-

Generate Gerber files: Export Gerber files for each layer of your 3D donut PCB, carefully labeling them so the manufacturer knows the layer order.

Other Creative PCB Shape Ideas

In addition to a 3D donut, here are some other unique PCB shape ideas to get your creative juices flowing:

| Shape | Description | Applications |

|---|---|---|

| Hexagon | A six-sided polygon | Modular devices, tile-based systems |

| Heart | A stylized heart shape | Wearables, IoT devices, Valentine’s Day projects |

| Star | A star shape with any number of points | Decorative lighting, LED displays |

| Mobius Strip | A looped shape with a half-twist | Art pieces, math/science demos |

| Custom Logo | A PCB outline matching a logo or graphic | Branded products, promotional items |

The possibilities are endless – let your imagination run wild!

Tips for Manufacturing Unusual PCB Shapes

Once you’ve designed your uniquely-shaped PCB, you’ll need to get it manufactured. Here are some tips for ensuring a smooth fabrication process:

-

Choose an experienced manufacturer: Look for a PCB fab house that has experience with unique shapes and can advise you on best practices.

-

Communicate early and often: Work closely with your manufacturer during the design and prototyping phase to identify any issues and refine your design for optimal manufacturability.

-

Consider panelization: Depending on the shape, panelizing multiple copies of your PCB in an array may be more cost-effective than manufacturing them individually.

-

Plan for extra time: Manufacturing a uniquely-shaped PCB may take longer than a standard rectangular board, so plan accordingly.

Frequently Asked Questions

-

Can I create any shape of PCB?

In theory, yes – but in practice, some shapes are much easier to manufacture than others. Extremely intricate shapes with thin areas or small cutouts can pose challenges. It’s always best to consult with your PCB manufacturer to determine what shapes are feasible. -

Is it more expensive to manufacture a unique PCB shape?

It can be, especially for very complex shapes that require special tooling or extra processing steps. Simple shapes like circles or hexagons are usually more affordable. Get quotes from multiple manufacturers to compare costs. -

What’s the minimum thickness possible for a 3D donut PCB?

The minimum thickness will depend on your components and PCB manufacturer’s capabilities. In general, each “slice” of the donut needs to be thick enough to accommodate your tallest components. Consult with your manufacturer for specific guidance. -

Can I 3D print a uniquely-shaped PCB?

You can 3D print a substrate to serve as the base for a PCB, but you can’t 3D print the actual copper traces and components. 3D printing can be a good option for prototyping the overall shape and fit of your PCB before proceeding with fabrication. -

Are there any performance benefits to using an unusual PCB shape?

In some cases, yes. A circular PCB can provide better angular coverage for antennas or sensors, for example. However, in most cases, the primary benefits are aesthetic and space efficiency rather than electrical performance.

Conclusion

Creating a 3D donut or other unique shape for your PCB design is a fun way to add creativity and visual interest to your project. With careful planning and attention to manufacturability, you can bring even the wildest design ideas to life.

Remember to work closely with your PCB manufacturer, consider the structural and functional implications of your chosen shape, and don’t be afraid to think outside the rectangle!

No responses yet