Introduction to Circuit-Drawing

Drawing a circuit board can seem like a daunting task, especially for beginners. However, with the right tools and techniques, anyone can create a simple yet functional circuit board. In this article, we’ll walk you through the process of drawing a circuit board, from gathering the necessary materials to finalizing your design.

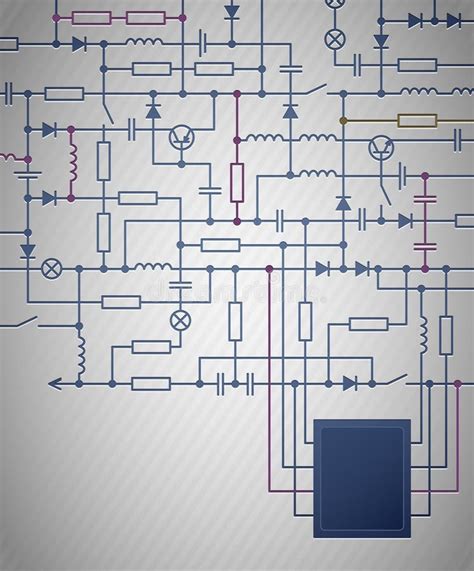

What is a Circuit Board?

A circuit board, also known as a printed circuit board (PCB), is a flat board made of insulating material, such as fiberglass or plastic, with conductive pathways etched or printed onto its surface. These pathways, called traces, connect various electronic components, such as resistors, capacitors, and integrated circuits, to form a complete electronic circuit.

Why Draw a Circuit Board?

Drawing a circuit board is an essential skill for anyone interested in electronics, whether you’re a hobbyist, a student, or a professional. By creating your own circuit boards, you can:

- Customize your electronic projects to suit your specific needs

- Save money by avoiding the cost of purchasing pre-made circuit boards

- Gain a deeper understanding of how electronic circuits work

- Develop your problem-solving and design skills

Materials and Tools Needed for Circuit-Drawing

Before you start drawing your circuit board, you’ll need to gather the following materials and tools:

Essential Materials

| Material | Description |

|---|---|

| Copper-clad board | A board made of insulating material with a layer of copper on one or both sides |

| Permanent marker | Used for drawing the Circuit design on the copper-clad board |

| Etchant solution | A chemical solution used to remove unwanted copper from the board |

| Drill bits | Used for drilling holes in the board for component leads |

| Soldering iron and solder | Used for soldering components onto the board |

Optional Materials

| Material | Description |

|---|---|

| Ruler or straightedge | Helps in drawing straight lines and accurate measurements |

| Pencil and eraser | Useful for sketching out your design before using the permanent marker |

| Tweezers | Helps in handling small components during soldering |

| Magnifying glass | Assists in inspecting the board for any defects or errors |

Step-by-Step Guide to Drawing a Circuit Board

Now that you have your materials and tools ready, let’s dive into the process of drawing your circuit board.

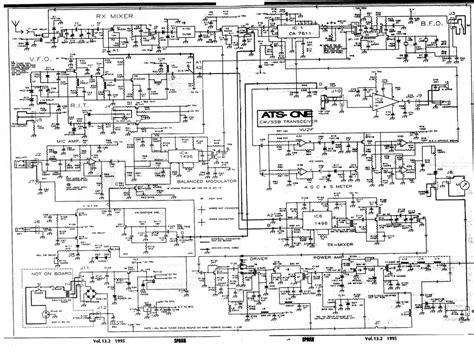

Step 1: Design Your Circuit

The first step in drawing a circuit board is to design your electronic circuit. This involves selecting the appropriate components and determining how they will be connected. You can use Circuit design software, such as EasyEDA or KiCad, to create a schematic diagram of your circuit.

Step 2: Transfer Your Design to the Copper-Clad Board

Once you have your circuit design ready, it’s time to transfer it to the copper-clad board. Here’s how:

- Clean the copper-clad board with steel wool or fine sandpaper to remove any oxidation or dirt.

- Place your schematic diagram or printout of your circuit design on the copper side of the board.

- Using a permanent marker, carefully trace the component outlines and traces onto the copper surface.

- Remove the schematic diagram or printout, and check that all lines and shapes are clearly visible on the copper.

Step 3: Etch the Circuit Board

With your design transferred to the copper-clad board, you can now etch away the unwanted copper using an etchant solution. Follow these steps:

- Prepare the etchant solution according to the manufacturer’s instructions.

- Immerse the board in the etchant solution, making sure that the copper side is facing up.

- Agitate the solution gently to ensure even etching.

- Periodically check the board to see if all the unwanted copper has been removed. This process usually takes between 10 to 30 minutes, depending on the strength of the etchant and the size of your board.

- Once etching is complete, remove the board from the solution and rinse it thoroughly with water.

Step 4: Drill Holes for Component Leads

After etching, you’ll need to drill holes in the board for the component leads. Use a drill bit that is slightly larger than the component leads to ensure a snug fit. Be careful not to apply too much pressure while drilling, as this can cause the board to crack or break.

Step 5: Solder the Components

With the holes drilled, you can now solder the components onto the board. Here’s how:

- Insert the component leads through the appropriate holes on the board.

- Bend the leads slightly to hold the components in place.

- Heat up your soldering iron and apply a small amount of solder to the tip.

- Touch the soldering iron to the component lead and the copper pad simultaneously, allowing the solder to flow and create a strong connection.

- Repeat this process for all components.

Step 6: Inspect and Test Your Circuit Board

Once all components are soldered in place, inspect your circuit board for any errors or defects. Check for the following:

- Correct component placement

- Proper soldering joints (no cold joints or excessive solder)

- Unintentional short circuits or broken traces

If everything looks good, it’s time to test your circuit board. Connect a power source and use a Multimeter to check for continuity and proper voltage levels. If your circuit functions as intended, congratulations! You’ve successfully drawn and assembled your own simple circuit board.

Tips and Tricks for Circuit-Drawing Success

To help you achieve the best results when drawing your circuit board, consider these tips and tricks:

- Always wear safety goggles and gloves when handling etchant solutions and other chemicals.

- Work in a well-ventilated area to avoid inhaling fumes from the etchant solution or solder.

- Use a high-quality permanent marker for drawing your circuit design to ensure clean, precise lines.

- If you make a mistake while drawing your design, you can remove the ink with a cotton swab dipped in acetone or rubbing alcohol.

- When soldering, make sure to heat the component lead and the copper pad simultaneously to create a strong, reliable connection.

Common Mistakes to Avoid in Circuit-Drawing

Avoid these common mistakes to ensure your circuit board functions properly and safely:

- Using a low-quality copper-clad board that may have defects or inconsistencies in the copper layer.

- Drawing traces that are too thin or too close together, which can lead to short circuits or signal interference.

- Overheating components or the board while soldering, which can cause damage or reduce the lifespan of your circuit.

- Forgetting to clean the board thoroughly after etching, which can lead to poor soldering or corrosion over time.

- Not testing your circuit board before powering it up, which can result in damage to components or even personal injury.

Frequently Asked Questions (FAQ)

-

Q: Can I use any type of paper for transferring my circuit design to the copper-clad board?

A: It’s best to use a printout or a schematic diagram on regular paper. Avoid using glossy or thick paper, as this can make it difficult to trace the design accurately. -

Q: How long does it take to etch a circuit board?

A: The etching process typically takes between 10 to 30 minutes, depending on the size of your board and the strength of the etchant solution. Always follow the manufacturer’s instructions for the best results. -

Q: Can I reuse the etchant solution?

A: Yes, you can reuse the etchant solution several times until it becomes saturated with copper and loses its effectiveness. Store the used solution in a labeled container for future use. -

Q: What should I do if I accidentally over-etch my circuit board?

A: If you’ve over-etched your board and removed too much copper, you may need to start over with a new copper-clad board. To avoid this, periodically check the board during the etching process and remove it from the solution as soon as all the unwanted copper has been removed. -

Q: How can I make my circuit board more durable?

A: To make your circuit board more durable, consider applying a protective coating, such as a conformal coating or a soldermask, after soldering your components. This will help protect your board from moisture, dust, and other environmental factors that can cause damage over time.

Conclusion

Drawing a simple circuit board may seem challenging at first, but with practice and patience, anyone can master this essential skill. By following the steps outlined in this article and keeping the tips and tricks in mind, you’ll be well on your way to creating your own custom circuit boards for your electronic projects.

Remember to always prioritize safety when working with chemicals and soldering equipment, and don’t be discouraged if your first attempts aren’t perfect. With each circuit board you draw, you’ll gain valuable experience and improve your skills, opening up a world of possibilities in the fascinating field of electronics.

No responses yet