Introduction to PCB Layers

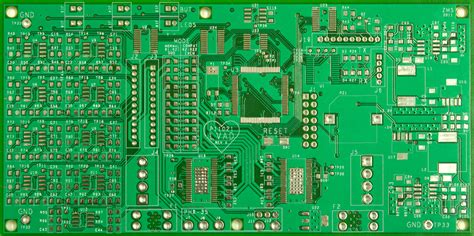

Printed Circuit Boards (PCBs) are essential components in modern electronic devices. They provide a platform for electrical components to be mounted and connected, enabling the device to function as intended. PCBs can be categorized based on the number of layers they have, ranging from single-layer to multilayer boards. In this article, we will focus on Multilayer PCBs and discuss how to determine the optimal number of layers for a given design.

What are Multilayer PCBs?

Multilayer PCBs are boards that consist of three or more conductive layers. These layers are separated by insulating materials, typically fiberglass or resin, and are interconnected through vias (vertical interconnect access). The use of multiple layers allows for more complex circuit designs and higher component density compared to single or double-layer boards.

Advantages of Multilayer PCBs

- Increased circuit density

- Improved signal integrity

- Better power distribution

- Reduced electromagnetic interference (EMI)

- Enhanced mechanical strength

Factors Influencing the Number of PCB Layers

When determining the number of layers for a multilayer PCB, several factors must be considered. These factors include:

1. Circuit Complexity

The complexity of the circuit design is a primary factor in determining the number of layers required. As the number of components and connections increases, so does the need for additional layers to accommodate them. Complex designs with high component density, such as those found in smartphones or laptops, often require a higher number of layers compared to simpler designs.

2. Signal Integrity

Signal integrity is crucial in ensuring the proper functioning of electronic devices. As the frequency of signals increases, the risk of signal degradation and crosstalk also increases. Multilayer PCBs can help mitigate these issues by providing dedicated layers for power and ground planes, as well as by allowing for controlled impedance routing. The number of layers required to maintain signal integrity depends on the frequency and sensitivity of the signals being transmitted.

3. Power Distribution

Efficient power distribution is another important factor in determining the number of PCB layers. Dedicated power and ground planes help reduce voltage drops and minimize noise in the power supply. As the power requirements of the circuit increase, additional layers may be necessary to ensure proper power distribution and to prevent voltage drops across the board.

4. EMI and Noise Reduction

Electromagnetic interference (EMI) and noise can cause significant problems in electronic devices, leading to reduced performance and even malfunctions. Multilayer PCBs can help reduce EMI and noise by providing shielding and by allowing for the separation of sensitive signals from potential sources of interference. The number of layers required for effective EMI and noise reduction depends on the specific requirements of the device and its operating environment.

5. Manufacturing Constraints

The manufacturing process and available technologies also play a role in determining the number of PCB layers. Some manufacturers may have limitations on the maximum number of layers they can produce, while others may specialize in high-layer count boards. Additionally, the choice of materials, such as the type of laminate or the thickness of the copper, can impact the feasibility and cost of manufacturing a given number of layers.

Determining the Optimal Number of PCB Layers

To determine the optimal number of layers for a multilayer PCB, designers must consider all of the factors mentioned above and balance them against the specific requirements of the project. The following steps can help guide the decision-making process:

Step 1: Assess Circuit Complexity

Begin by evaluating the complexity of the circuit design. Identify the number of components, their sizes, and the connections between them. This information will provide a baseline for estimating the number of layers required to accommodate the circuit.

Step 2: Analyze Signal Requirements

Next, consider the signal requirements of the circuit. Identify the frequencies and sensitivities of the signals being transmitted, as well as any potential sources of interference. This information will help determine the need for dedicated signal layers and controlled impedance routing.

Step 3: Evaluate Power Distribution Needs

Assess the power requirements of the circuit and identify any potential issues with voltage drops or power supply noise. Determine the need for dedicated power and ground planes, and consider the placement of these planes within the layer stack.

Step 4: Consider EMI and Noise Reduction

Evaluate the EMI and noise reduction requirements of the device and its operating environment. Identify potential sources of interference and determine the need for shielding or signal separation. This information will help guide the placement of layers and the use of shielding techniques.

Step 5: Review Manufacturing Constraints

Finally, consider the manufacturing constraints and available technologies. Consult with the chosen PCB manufacturer to understand their capabilities and limitations, as well as any cost implications associated with the number of layers.

Common PCB Layer Configurations

While the optimal number of layers for a multilayer PCB varies depending on the specific requirements of the project, there are some common layer configurations used in the industry. These configurations provide a starting point for designers and can be adapted to meet the needs of a particular design.

| Number of Layers | Typical Configuration |

|---|---|

| 4 | Signal – Ground – Power – Signal |

| 6 | Signal – Ground – Signal – Signal – Power – Signal |

| 8 | Signal – Ground – Signal – Power – Ground – Signal – Power – Signal |

| 10 | Signal – Ground – Signal – Power – Ground – Signal – Power – Signal – Ground – Signal |

| 12 | Signal – Ground – Signal – Power – Ground – Signal – Signal – Power – Ground – Signal – Power – Signal |

It’s important to note that these are just examples, and the actual configuration will depend on the specific requirements of the design.

FAQ

1. What is the minimum number of layers in a multilayer PCB?

The minimum number of layers in a multilayer PCB is three. This configuration consists of a signal layer, a power or ground layer, and another signal layer.

2. How does the number of layers affect the cost of a PCB?

Generally, as the number of layers increases, so does the cost of manufacturing the PCB. This is due to the increased complexity of the manufacturing process and the additional materials required. However, the cost increase is not always linear and may depend on the specific manufacturer and the volume of boards being produced.

3. Can the number of layers be changed during the design process?

Yes, the number of layers can be changed during the design process. However, it’s best to establish the required number of layers early in the design phase to avoid significant rework and potential delays. Changes made later in the process may also impact the cost and manufacturing timeline.

4. What is the maximum number of layers that can be used in a PCB?

The maximum number of layers in a PCB is not strictly defined and can vary depending on the manufacturer’s capabilities. Some specialized manufacturers can produce PCBs with over 50 layers. However, most commercial PCBs rarely exceed 20 layers due to the increased complexity and cost associated with higher layer counts.

5. Are there any disadvantages to using a higher number of layers?

While a higher number of layers can offer benefits such as increased circuit density and improved signal integrity, there are some potential disadvantages. These include increased manufacturing complexity, higher costs, and potential issues with thermal management. It’s essential to strike a balance between the required functionality and the practical limitations of the design.

Conclusion

Determining the optimal number of layers for a multilayer PCB is a critical aspect of the design process. By considering factors such as circuit complexity, signal integrity, power distribution, EMI and noise reduction, and manufacturing constraints, designers can make informed decisions that balance the specific requirements of the project with practical limitations.

While common layer configurations can provide a starting point, the ultimate goal is to create a PCB design that meets the functional and performance requirements of the device while remaining cost-effective and manufacturable. By following a systematic approach and collaborating with experienced PCB manufacturers, designers can ensure that their multilayer PCBs are optimized for their intended applications.

No responses yet