Introduction to PCB Layout and Altium Designer

Printed Circuit Board (PCB) layout is a crucial step in the electronic design process. It involves arranging electronic components and routing the connections between them on a PCB. A well-designed PCB layout ensures proper functionality, reliability, and manufacturability of the electronic device.

Altium Designer is a popular PCB design software that offers a comprehensive set of tools for schematic capture, PCB layout, and design documentation. It provides a user-friendly interface and advanced features to streamline the PCB design process.

In this article, we will guide you through the steps to create a PCB layout schematic using Altium Designer.

Prerequisites

Before starting with PCB layout in Altium Designer, ensure that you have the following prerequisites:

- Altium Designer software installed on your computer.

- Basic knowledge of electronic components and their symbols.

- Understanding of schematic capture and electrical circuits.

- Familiarity with PCB design concepts and terminology.

Step 1: Create a New Project

To begin, open Altium Designer and create a new project. Follow these steps:

- Click on “File” in the top menu bar and select “New Project.”

- Choose a project template or select “Empty Project” for a blank project.

- Specify the project name and location on your computer.

- Click “OK” to create the project.

Step 2: Create a Schematic

The first step in creating a PCB layout is to design the schematic. The schematic represents the electrical connections and components of your circuit. Follow these steps to create a schematic in Altium Designer:

- In the Projects panel, right-click on the project name and select “Add New to Project.”

- Choose “Schematic” from the available options.

- Specify a name for the schematic file and click “OK.”

- The schematic editor will open, providing a blank canvas to design your circuit.

Adding Components

To add components to your schematic:

- Click on the “Libraries” panel to access the component libraries.

- Browse through the libraries to find the desired component or use the search function to locate it quickly.

- Drag and drop the component from the library onto the schematic canvas.

- Repeat the process to add all the necessary components for your circuit.

Connecting Components

Once the components are placed, you need to establish the electrical connections between them. To connect components:

- Click on the “Place Wire” tool in the toolbar or press the “W” key.

- Click on the pin of the first component you want to connect.

- Move the cursor to the pin of the second component and click to create the connection.

- Continue connecting all the required pins and components.

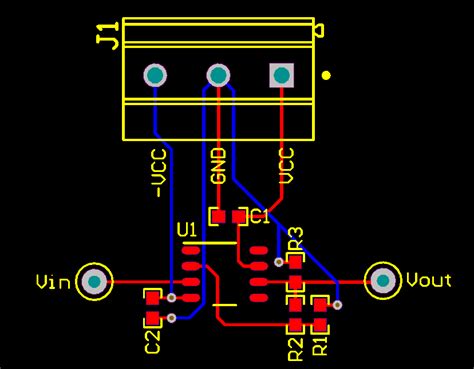

Adding Net Labels and Power Symbols

To improve the readability and organization of your schematic, you can add net labels and power symbols:

- Click on the “Place Net Label” tool in the toolbar or press the “N” key.

- Click on the wire where you want to place the net label.

- Enter a meaningful name for the net label.

- For power connections, click on the “Place Power Port” tool or press the “P” key.

- Click on the wire and select the appropriate power symbol from the library.

Step 3: Design Rules and Constraints

Before proceeding with PCB layout, it’s important to define the design rules and constraints. Design rules ensure that your PCB meets the manufacturing requirements and prevents potential issues. To set up design rules:

- Go to “Design” in the top menu bar and select “Rules.”

- In the PCB Rules and Constraints Editor, you can define various rules such as:

- Clearance rules: Specify the minimum spacing between components, traces, and other elements.

- Width rules: Set the minimum and maximum width of traces based on their current carrying capacity.

- Via rules: Define the size, drill, and spacing requirements for vias.

- Routing rules: Specify the routing guidelines, such as preferred routing directions and layer assignments.

- Customize the rules according to your PCB manufacturing capabilities and design requirements.

- Click “Apply” and “OK” to save the design rules.

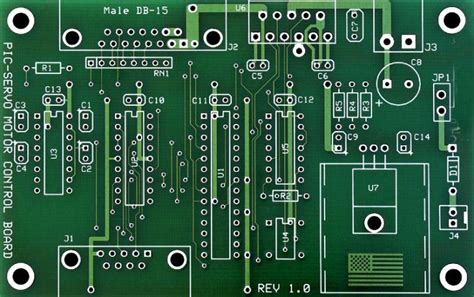

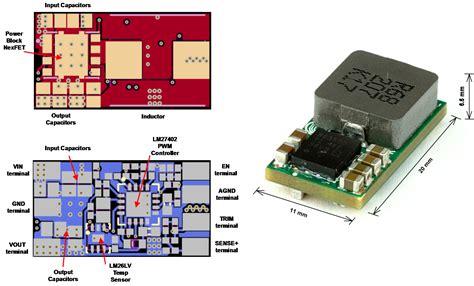

Step 4: PCB Layout

With the schematic design complete and design rules set up, you can now proceed with the PCB layout. The PCB layout process involves placing components and routing the connections on the physical board. Follow these steps:

Creating a PCB Document

- In the Projects panel, right-click on the project name and select “Add New to Project.”

- Choose “PCB” from the available options.

- Specify a name for the PCB file and click “OK.”

- The PCB editor will open, displaying a blank PCB workspace.

Placing Components

- In the PCB editor, go to “Tools” in the top menu bar and select “Component Placement.”

- The components from your schematic will be listed in the Components panel.

- Drag and drop the components onto the PCB workspace.

- Arrange the components in a logical and organized manner, considering factors such as component size, mounting holes, and board space.

Routing Traces

Once the components are placed, you can start routing the traces to establish the electrical connections. To route traces:

- Click on the “Route” tool in the toolbar or press the “R” key.

- Select the appropriate routing layer (e.g., Top Layer or Bottom Layer) from the Layers panel.

- Click on the pad or via of the first component you want to connect.

- Move the cursor to the pad or via of the second component and click to create the trace.

- Altium Designer will automatically route the trace based on the design rules you defined earlier.

- Continue routing all the necessary connections.

Placing Vias and Mounting Holes

Vias are used to connect traces on different layers, while mounting holes are used to secure the PCB to an enclosure or chassis. To place vias and mounting holes:

- Click on the “Via” tool in the toolbar or press the “V” key.

- Click on the location where you want to place the via.

- Select the appropriate via size and drill diameter from the Properties panel.

- For mounting holes, click on the “Hole” tool or press the “H” key.

- Click on the desired location for the mounting hole.

- Specify the hole size and other properties in the Properties panel.

Adding Copper Pours and Planes

Copper pours and planes are used to provide a low-impedance ground or power connection and to improve EMI shielding. To add copper pours and planes:

- Click on the “Pour” tool in the toolbar or press the “P” key.

- Select the desired layer and copper pour type (e.g., Solid, Hatched, or Void).

- Draw a closed boundary around the area where you want to place the copper pour.

- Altium Designer will automatically fill the area with copper based on the selected pour type and design rules.

Step 5: Design Rule Check (DRC)

Before finalizing your PCB layout, it’s crucial to run a Design Rule Check (DRC) to ensure that your design complies with the defined design rules and constraints. To run a DRC:

- Go to “Tools” in the top menu bar and select “Design Rule Check.”

- In the DRC dialog box, select the rules you want to check.

- Click “Run DRC” to start the check process.

- Altium Designer will analyze your PCB layout and report any violations or errors.

- Review the DRC report and make necessary modifications to resolve any issues.

Step 6: Generate Manufacturing Files

Once your PCB layout is complete and has passed the DRC, you can generate the manufacturing files required for PCB fabrication. The most common manufacturing files include Gerber files, drill files, and assembly files. To generate manufacturing files:

- Go to “File” in the top menu bar and select “Fabrication Outputs.”

- In the Fabrication Outputs dialog box, select the desired output formats (e.g., Gerber, NC Drill, Pick and Place).

- Configure the output settings, such as layer selection and file naming conventions.

- Click “OK” to generate the manufacturing files.

- Save the generated files in a designated location.

Tips and Best Practices

Here are some tips and best practices to keep in mind while creating a PCB layout schematic in Altium Designer:

- Keep the schematic organized and well-labeled for better readability and maintainability.

- Use consistent naming conventions for components, nets, and labels.

- Follow industry-standard component placement and orientation guidelines.

- Consider the signal integrity and EMI/EMC requirements of your design.

- Optimize component placement to minimize trace lengths and reduce signal interference.

- Use appropriate trace widths based on the current carrying capacity and signal integrity requirements.

- Provide adequate clearance between components, traces, and other elements to ensure manufacturability.

- Use ground planes and power planes to improve signal integrity and reduce EMI.

- Perform thorough design rule checks and make necessary adjustments before finalizing the layout.

- Collaborate with PCB manufacturers and assembly houses to ensure compatibility and manufacturability of your design.

FAQs

-

Q: What is the difference between a schematic and a PCB layout?

A: A schematic represents the electrical connections and components of a circuit, while a PCB layout is the physical representation of those connections on a printed circuit board. -

Q: Can I import an existing schematic into Altium Designer for PCB layout?

A: Yes, Altium Designer allows you to import schematics from various formats, such as OrCAD, Eagle, and KiCad. You can use the “File” > “Import” option to bring in an existing schematic. -

Q: How do I create custom footprints for components in Altium Designer?

A: Altium Designer provides a footprint editor where you can create custom footprints. You can access it by going to “Tools” > “Footprint Wizard” or by creating a new PCB Library project and adding a new footprint. -

Q: What are the common manufacturing files required for PCB fabrication?

A: The common manufacturing files include Gerber files (for copper layers, solder mask, and silkscreen), NC drill files (for drilling holes), and assembly files (such as pick and place files and bill of materials). -

Q: How can I ensure my PCB layout meets the manufacturing requirements?

A: To ensure your PCB layout meets the manufacturing requirements, follow these steps: - Define appropriate design rules and constraints based on the manufacturing capabilities.

- Perform thorough design rule checks (DRC) to identify and resolve any violations.

- Communicate with your PCB manufacturer and provide them with the necessary manufacturing files and specifications.

- Request a design for manufacturability (DFM) review from the manufacturer to catch any potential issues early in the process.

Conclusion

Creating a PCB layout schematic in Altium Designer involves a systematic approach, starting from schematic capture to PCB layout and generation of manufacturing files. By following the steps outlined in this article and adhering to best practices and design rules, you can develop a reliable and manufacturable PCB design.

Remember to keep your schematic organized, define appropriate design rules, optimize component placement and routing, and perform thorough design rule checks. Collaboration with PCB manufacturers and assembly houses is also essential to ensure the successful fabrication and assembly of your PCB.

With practice and experience, you will become proficient in using Altium Designer for PCB layout and be able to tackle complex design challenges efficiently.

| Step | Description |

|---|---|

| 1 | Create a new project in Altium Designer |

| 2 | Create a schematic and add components |

| 3 | Define design rules and constraints |

| 4 | Perform PCB layout, including component placement and routing |

| 5 | Run Design Rule Check (DRC) to ensure compliance |

| 6 | Generate manufacturing files for PCB fabrication |

By following these steps and utilizing the features and tools provided by Altium Designer, you can create professional-grade PCB layouts that meet your design requirements and manufacturing standards.

No responses yet